Total Productive Maintenance

In Field Training

27-29 March 2018 — Moscow

Practical Training to Start the Improvement Journey for a better Uptime, Maintenance Activities, and Cost Reduction.

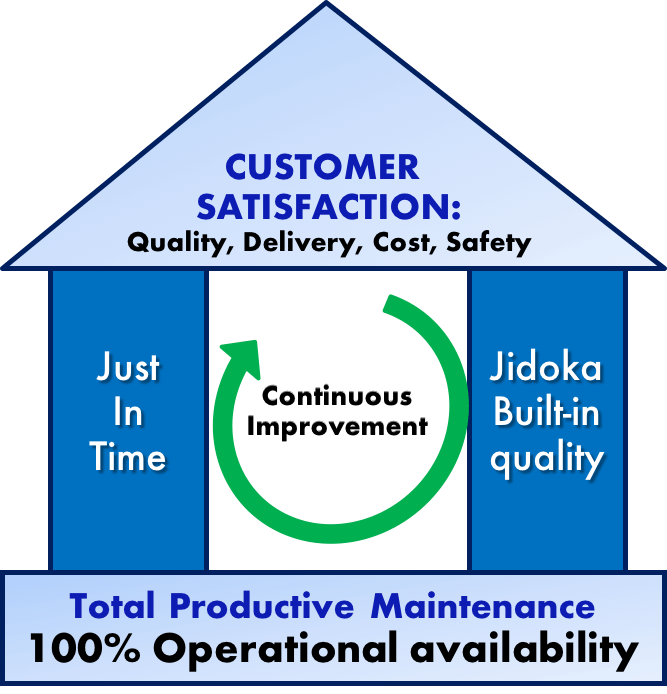

Why Total Productive Maintenance?

50 years ago Toyota recognized that the key to manufacturing success is when the machinery performs as expected from the design specifications.

The base of a successful production system is “Total Productive Maintenance (TPM)”

Many manufacturers soon realize in their pursuit of Lean that poor productivity is their main barrier to manufacturing excellence.

This training will give participants the foundation necessary to start the first steps of the TPM implementation.

Understand the TPM System

Identify and analyze the operational losses using TPM management tools and structure.

Team up with other managers

Share experiences and discuss with other colleagues from different industries

Genba Activities

We will apply different TPM concepts directly on the host plant process

Training Lenght:

24 Hours (3 days)

Investment:

950 Euro/ participant + VAT

Available seats

18 external participants

Who should attend?

General Managers, Managers and Supervisors in Maintenance, Lean Managers that would like to understand the implementation of TPM

Recommended Industries

Manufacturing Companies: Automotive, Electrical/Electronic, Pharmaceutical, Food & Beverages, Printing, Plastics, among others.

Main Benefits:

-

To get an overview on how to implement TPM in your company

-

How TPM improves the teamwork of maintenance, production, engineering, and management

-

Learn why TPM is at the base of TPS and how TPM will give your company a strong foundation for manufacturing excellence

-

Implement the first, basic TPM elements as a foundation for the complete TPM System.

Training Approach

-

TPM Training is oriented to develop solid Maintenance Management practices.

-

All the content is related as a whole Management System, as part of the General Production System.

-

This Training is not oriented to learn or develop technical skills (e.g. repair a motor, program a Robot, etc).

MODULE 1. Toyota’s Equipment Maintenance Theory

- The 4 Pillars of TPM activity. Toyota Total Productive Maintenance (TPM) Toyota’s Japanese Original version.

- 12 Important Items for TPM Management. Toyota’s Japanese Original version

MODULE 2. Failure Occurence Prevention

- Toyota Total Productive Maintenance Visual Elements to Facilitate Operation and Maintenance

- 5 Senses on the Shop Floor.

- Autonomous Maintenance: Steps for Implementing Operator’s Maintenance

- Visual Preventive Maintenance.

MODULE 3. Foundation Systems: HR Development for Maintenance and Production Personnel

- HR on Maintenance

- Fundamental Concepts: 4 major items for TL Role

MODULE 4. Hoshin Alignment: Management System applied to Maintenance

- Toyota FMDS for Maintenance Management.

MODULE 5. Implementing TPM

- Strategy to Implement TPM on Plant

Host Company: BOA Below Technologies Romania

The BOA Group is one of the world’s leading manufacturers for flexible mechanical elements for the automotive and aerospace industry as well as for a wide range of industrial applications.

The headquarters is based in Stutensee, Germany. Today, the BOA Group consists of 15 subsidiaries and shareholdings in 13 countries.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

BOA Romania is located in Arad. The plant started its operations in July 2014 producing metal hoses and exhaust gas recirculation pipes for the automotive industry as well as V-clamps for industrial applications.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

In the industrial division, the BOA Group delivers flexible elements for applications in the Energy sector, Shipbuilding, Rail and Heavy Engine industry. Customized expansion joints are designed for Petrochemical, Chemical as well as Oil & Gas Pipelines.

Precision metal bellows and ultra clean metal hoses complete the product range and offer high tech product applications in the Vacuum, Semiconductor & Magnet Technology market.

Zona Industriala Nord-Vest, str. IV, Nr. 13, Arad, Romania.

Instructor

Gustavo Varela

+17 years as Global Continuous Improvement Leader

Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard and Master Black Belt Champion for Daltile. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy.

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles.

Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes:

- Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving),

- Toyota Kata for development,

- Supply Chain Management,

- TPM,

- Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.)

- Lean Office approach.

On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts.

Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.