Toyota Kata In Field Training

Develop your leaders as problem solvers and coaches of the improvement journey

10-12 July

Toyota Kata In field Training

Develop your leaders as problem solvers and coaches of the improvement journey

10-12 July

Learn the management way to achieve challenging objectives, and developing leaders as coaches for creating a culture of continuous improvement.

In Field Training: we will learn and practice on the shop floor

Practice the Kata

Practice several rounds the improvement and coaching Kata receiving feedback from ALFRA Coaches

Group Discussions

Learn & share experiences with managers from different industries, with team based activities.

Shop Floor Implementation

Perform experiments and coaching cycles on the shop floor from the host company

Who should attend?

Senior managers, leaders and middle managers that are interested in creating a sustainable culture of continuous improvement through use of the cutting edge management methodology of Toyota Kata.

Dates: 10-12 July Location: BOA RBT, Arad Romania.

Language: English

Key benefits

You will learn the fundamentals of how to apply the improvement and coaching routines in your organization

- Providing a systematic, scientific routine that can be applied to any problem or challenge.

- Commonizing how the members of an organization develop solutions.

- Migrating managers toward a role of coach and mentor, by having them practice coaching cycles.

- Framing PDCA in a way that has people taking small steps every day

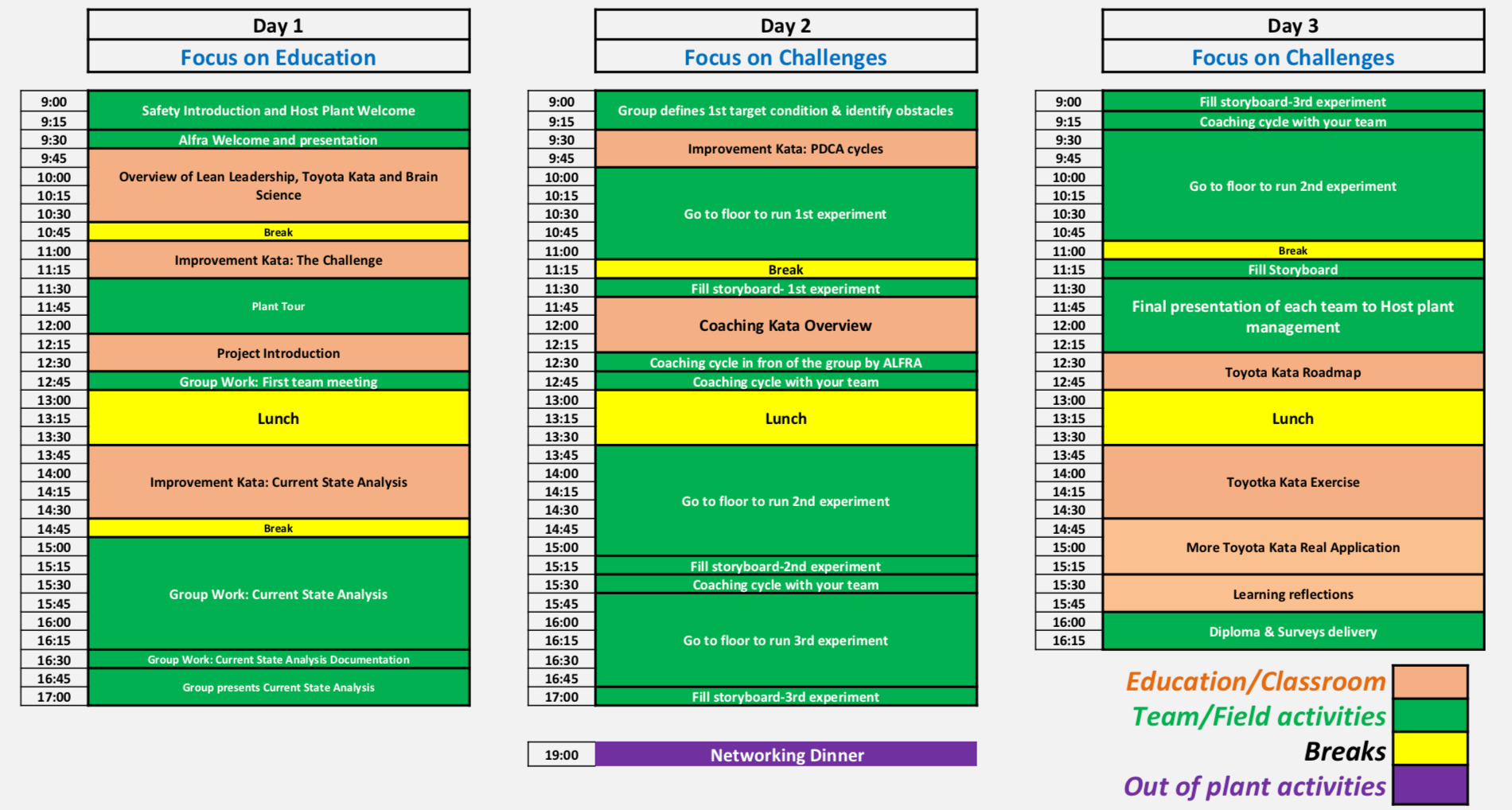

TRAINING AGENDA

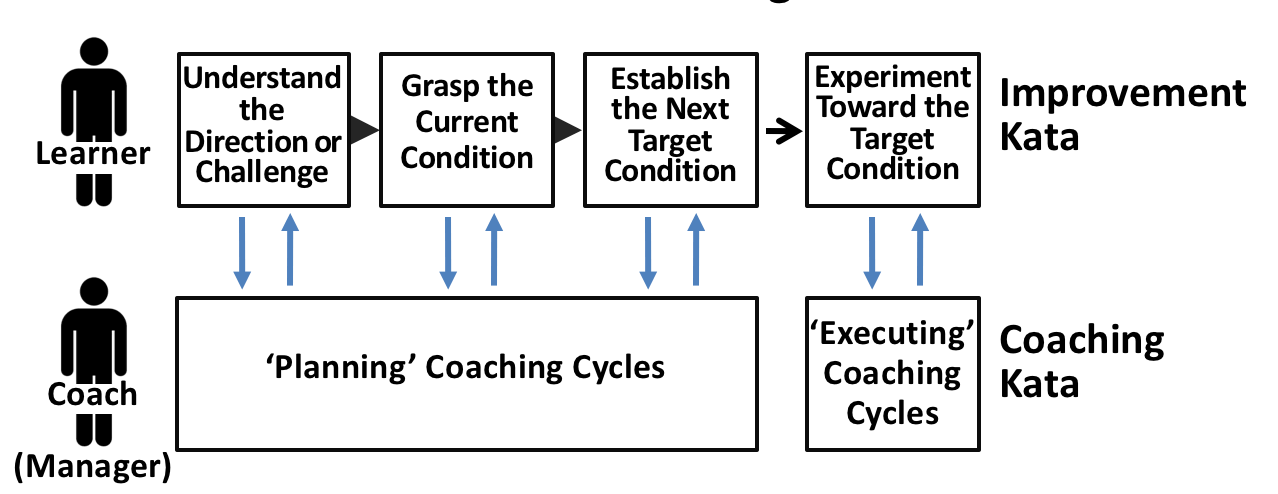

The Improvement Kata

A four-step sequence that is a systematic, scientific pattern for managing teams. Practicing it helps any team get better at meeting goals and challenges.

The Coaching Kata

A set of teaching routines that help you develop coaching skill. It is a coaching pattern that helps managers teach improvement thinking and acting.

Host Company

Host Company: BOA RBT – Arad, Romania

BOA RBT – Arad Plant

The BOA Group is one of the world’s leading manufacturers for flexible mechanical elements for the automotive and aerospace industry as well as for a wide range of industrial applications.

The headquarters is based in Stutensee, Germany. Today, the BOA Group consists of 15 subsidiaries and shareholdings in 13 countries.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

BOA Romania is located in Arad. The plant started its operations in July 2014 producing metal hoses and exhaust gas recirculation pipes for the automotive industry as well as V-clamps for industrial applications.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

In the industrial division, the BOA Group delivers flexible elements for applications in the Energy sector, Shipbuilding, Rail and Heavy Engine industry. Customized expansion joints are designed for Petrochemical, Chemical as well as Oil & Gas Pipelines.

Precision metal bellows and ultra clean metal hoses complete the product range and offer high tech product applications in the Vacuum, Semiconductor & Magnet Technology market.

Instructor

Francisco Ocejo – Toyota Kata Ambassador

Francisco Ocejo

Toyota Kata Ambassador

Francisco is a Toyota Kata Ambassador and Pioneer to spread the Toyota Kata in America, he has been applying the Kata approach with his colleague Dr. Jeff Liker ( author of the best seller the Toyota Way) and many other Coaches in companies with the highest TPS people development.

Francisco is a Toyota Kata Ambassador and Pioneer to spread the Toyota Kata in America, he has been applying the Kata approach with his colleague Dr. Jeff Liker ( author of the best seller the Toyota Way) and many other Coaches in companies with the highest TPS people development.

He has been learning, applying, and teaching the Toyota Production System in Canada, USA, Mexico, Brazil, Costa Rica, & Europe. He has taught and applied Lean Manufacturing concepts from the senior management level to the operational levels closest to Gemba for over 150 companies from international corporations, to mid-size and small family businesses from different industry sectors

Francisco is a former leader & manager of the Lean Culture Transformation working with BlackBerry (RIM), Palm, HTC as their principal customers. This transformation involved over 5,000 people. The Business Unit started with scrap of over $1 Million a month, high absenteeism, low productivity, long production lead times and internal and supplier quality issues.

By coaching the Leadership team through a Lean Transformation beginning with the training people through all levels they were able to reduce scrap to only 0.035%, achieve 100% On-time-delivery, improve process flow and lead times and dramatically increase Direct Labor Efficiency.

Francisco has taught classes for students in over 15 Universities, lecturing in various Congresses in Mexico on TPS and Kata.

Francisco holds a Bachelors of Science in Industrial and Systems Engineering from the Monterrey Technical Institute. He also has MBA from IPADE. He is a certified Six Sigma Black Belt from the Institute of Industrial Engineers, and has certifications in the Theory of Constraints and Thinking Process from the EGADE of the Monterrey Technical Institute.

Recent Kata Workshops:

Toyota Kata at TAC Michigan – Special guest: Mike Rother

Toyota Kata in Field at ifm Efector Sibiu, Romania

Toyota Kata at Mercedes Benz

Toyota Kata at Avanzar – Tier 1 Toyota Supplier

Receive the brochure with all details in your email

Coaching, Leadership, Lean, Toyota, Kata, Development, Problem Solving, 8D, Lean Management, PDCA, Scientific thinking, process improvement,