Lean Implementation Cases

Benefits & Learnings from different industries.

We have worked with over 1000 organizations around the world, leaders of their industry segment, helping them to enhance the way of how they grow and sustain a culture of continuous learning and improvement.

Another part of the collaboration with our customers is to help them to achieve solid results, here are examples from different industries.

How ALFRA can help you on this journey

Using operational excellence Models, like the Shingo Model, customers in the mining industry have achieved outstanding improvements in a 2-years implementation.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Equipment availability

Contact us to discuss how lean can be implemented in your industry.

Automotive Industry

We have worked with the automotive industry leaders, Automakers like Ford, Fiat-Chrysler, Daimler, and top tier suppliers, heallping them to improve their quality, productivity, and delivery indicators using the kaizen approach.

Some of the benefits:

- 20% Scrap reduction

- 50% Lead time reduction

- 30% Productivity Improvement

- 40% First time quality Improvement

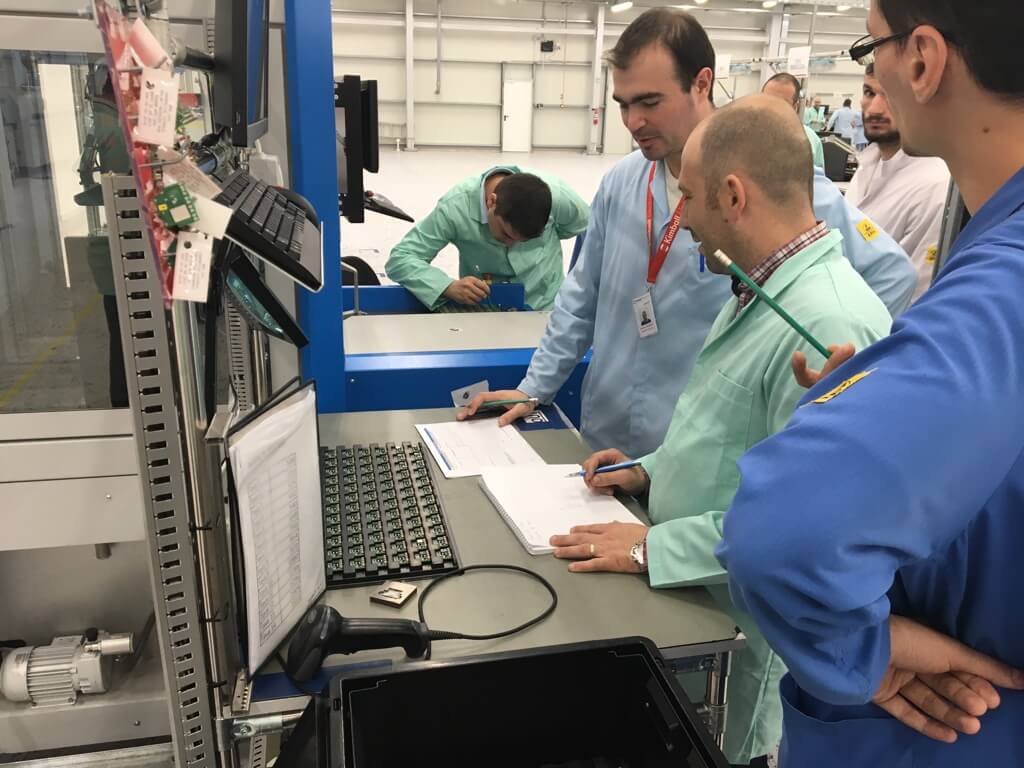

Electronics Industry

Worker safety is one of the most important factors to take into consideration. Using the Yamazumi method, we reduced not only Muri, Mura, and Muda (Waste) for our clients, but also the Lead time.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Reduction of quality issues

Mining Industry

Using operational excellence Models, like the Shingo Model, customers in the mining industry have achieved outstanding improvements in a 2-years implementation.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Equipment availability

Food & Drinks Industry

With a focus on product safety, increase equipment availability, and flexibility, we have supported customers from food and beverage to increase their performance by developing their teams to sustain and improve working conditions.

Some of the benefits:

- 20% Production Output

- 5% OEE Improvement

- 20% Productivity Improvement

- 30% Equipment availability increase

- 50% reduction of batch size (inventory)

Financial Services Industry

By standardizing the operational processes and giving more power to the front-line staff, we reduced operational risk and eliminated waste.

Some of the benefits:

- Productivity Improvement

- Improvement on Employee Rotation

- Elimination of waste

- A Sustainable Lean Cultural Transformation

Energy Industry

We have helped companies from the energy industry expand their business capacity without spending money on an expanded or new facility.

Some of the benefits:

- Safety Improvement

- Quantification of cost and value

- Productivity Improvement

- Space reduction

Printing & Packing Industry

Using the Single Minute Exchange of Die (SMED) method, developed by Shigeo Shingo, customers in the printing and Packing Industry have achieved outstanding improvements in their Changeover Processes.

Some of the benefits:

- Major Changeover Reduction

- Zero production impact in Change Over

- Lead Time Improvement

- Equipment availability

Aerospace Industry

Through optimization of the material and information flow, our customers from the Aerospace industry achieved superior quality and, as a result, elimination of scrap and rework.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Quality Improvement

- Scrap elimination

Pharmaceutical industry

Using operational excellence Models, like the Shingo Model customers in the mining industry has achieve outstanding improvements in a 2 years implementation.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Equipment availability

Project-Based Companies

Using operational excellence Models, like the Shingo Model customers in the mining industry has achieve outstanding improvements in a 2 years implementation.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Equipment availability

Metallurgy Industry

Using operational excellence Models, like the Shingo Model customers in the mining industry has achieve outstanding improvements in a 2 years implementation.

Some of the benefits:

- Safety Improvement

- Lead time reduction

- Productivity Improvement

- Equipment availability