Six Sigma Black Belt

Lean techniques eliminate wasteful activities to increase the flow of value, while Six Sigma is a disciplined method for meeting customers’ expectations and eliminating defects in any process, together, both methods enable a culture of continuous learning and improvement

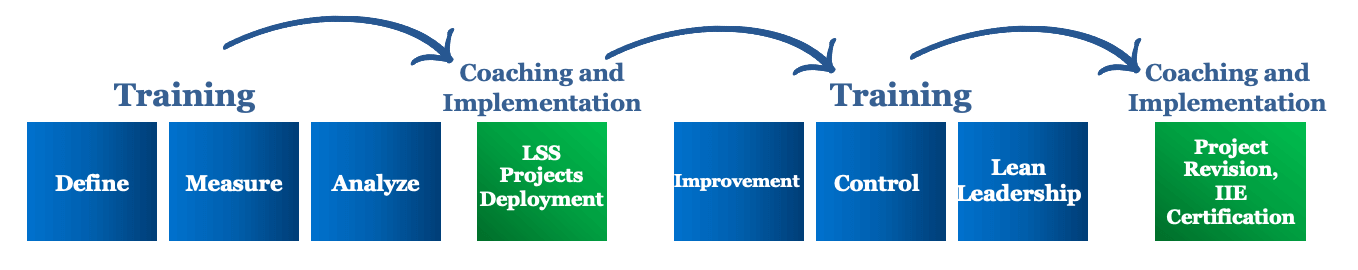

Participants will become proficient in all of the analytical tools necessary to define, measure, analyze, improve, implement and control improvement projects. Participants must have a windows based computer running Microsoft Office and Minitab ( we can provide a 30 days trial) for the training program. Participants require previous knowledge equivalent to a Green Belt certification level to take this training.

Program duration: 15 days

The proposed project must be defined before the training starts

10 Days of Training

3 days or project advisory (coaching)

2 preparation sessions (web meeting) for IIE certification exam

Participants will learn:

- Develop lean process flows

- Implement lean in your organization

- Reduce cycle time by minimizing wait times

- Analyze process data using comprehensive statistical methods

- Control the process to ensure that improvements are used

- Define an opportunity for improving customer satisfaction

- Implement the recommended improvements

- Improve existing processes by reducing variation

Six Sigma Black Belt – Body of Knowledge:

- What is Lean + Six Sigma

- Six Sigma vs. Lean – DMAIC vs. PDCA

- Why do we need both parts

- The place of Six sigma in the company strategy

- Introduction to Six Sigma

- Six Sigma Deployment

- Project Charter (Definition)

- Basic Statistics

- Decision Trees

- QFD

- Mapping Process (VSM, flowchart, SIPOC, Spaghetti)

- Cause and Effect Matrix

- Measurement System Analysis

- Capacity Analysis

- Measurement System Analysis pt. 2

- Analysis of Failure Mode and Effects

- Methods Graphs 1

- Advanced Statistics

- Methods Figures 2

- Central Limit Theorem

- Test of Hypothesis

- Means Test

- Variances test

- Proportions test

- ANOVA

- Confidence & Confidence intervals

- Value Flow Analysis

- Introduction to Design of Experiments

- Full Factorial Design

- 2k Factorial Design

- Chi-Square tests

- Regression and Correlation

- Linear, Curvilinear, Multivariate

- Multiple Regression

- Yamazumi Management

- Flexibility tools: 5s, Visual Management, Std Work.

- Confidence tools: Poka Yoke, Quality at the source

- Flexibility tools: SMED, TPM basics,

- Flow Management: One-piece flow and Pull system

- Introduction to Control

- Control Methods

- Control plan

- Power and sample size for hypothesis testing

- Factorial design 2k-p

- Statistical process control

- Projects & Team Management

- Power and sample size for Design of Experiments

- The statistical process control attribute

- Lean Sustaining Methods

- Cultural Enables

- Leadership development model

- Developing yourself to develop others

- Coaching your team for continuous improvement.

- Align business strategy to operational excellence

This training includes the certification process for the Institute of Industrial Engineers (IIE).

IIE is the world’s largest professional society dedicated to the support of the industrial engineering profession and individuals involved with improving quality and productivity. Founded in 1948, IIE is an international, nonprofit association that provides leadership for the application, education, training, research, and development of industrial engineering.

Do you want to go further? We can answer any question.

5s training, 5s, 5s implementation, 5s deployment, IE, process optimization, process improvement, time measurement, ergonomics training, ergocheck, Layout optimization, Layout design, MTM, motion analysis