Kanban Workshop

The key for a successful Production System

In-field Training

While manufacturing efficiency is important, it doesn’t stand alone, one of the keys to Lean’s success is the role that Production Planning and Control plays in the organization.

The voice of the customer must be clear and consistent through the manufacturing flow, communication from the Customer, Suppliers, Manufacturing, and Engineering is key for success.

The kanban workshop will give the participant a chance to create a Production Forecast and Firm Plan, create a weekly plan, and create a Kanban control board to regulate production (replenishment) and confirm production readiness (Man, Method, Machine, and Material).

Participants will split into teams to perform activities in selected processes.

Applications on Shop Floor

We will perform activities directly in the process area.

Real Case Examples

We will review examples of implementations from other companies

Team Work + Guidelines for your own Implementation

We will have teamwork exercises and plan for your own implementation

Training Length: 3 days

Aimed to: General Managers, Managers & Leaders in Maintenance, Manufacturing, Engineering and Continuous improvement.

What we will practice:

- Create a smoothed weekly Production Plan that will absorb order fluctuation

- Create a Kanban system to drive production while maintaining minimum and maximum inventory levels of finished goods

- Measure the results of our trial.

- Understanding of how to prioritize and react to unexpected work changes

- Learning how to adjust daily production based on Pull System

- Learning how to make the flow to be self-managed by people doing the work

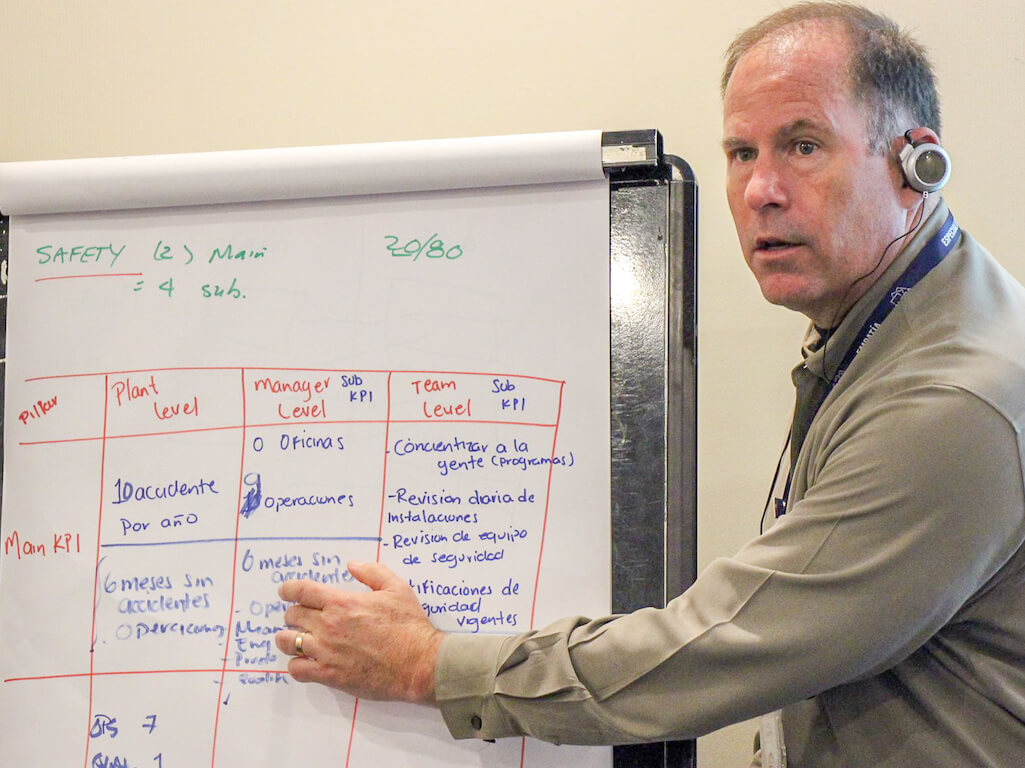

Instructed by seasoned Lean Coaches

Edgar Cardenas

Lean Advisor & Coach – Europe Operations Director

Edgar has worked the last years in countries like Romania, Hungary, Russia, Mexico, Colombia, Spain and USA…, providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes, in several industries including: Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, among others.

He recently provide support to companies like Bosch, Hino Motors, Mercedes Benz, Kimball, Zebra technologies, Takata, Inteva Products, Dawn Foods, BOA, Mars, Rubbermaid, Faist Group, Emerson, Exide, Harsha Engineers, Steelcase..

-

Lean for Business Processes corporate trainer for several companies

-

Operational Excellence speaker at several international Lean Conferences & Summits.

-

He has developed in Lean Management over 1000 managers & leaders

-

Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta , Georgia.

-

Edgar has received direct coaching and professional development from renowned leaders like:, Ritsuo Shingo (Former Toyota President ), PhD. Jeffrey Liker (The Toyota Way), Gary Convis (Former VP at Toyota N.A. )

DO YOU WANT TO GO FURTHER? WE CAN ANSWER ANY QUESTION

Lean Manufacturing, 5s, Visual management, 8D Problem Solving, Problem Solving Training, 8D Training, Curs 8D, training 8D, PDCA training, 8D Principles, Problem Solving Principles, Problem Solving Implementation, Lean Training