ALFRA Consulting Approach

Understand our Transformational Model

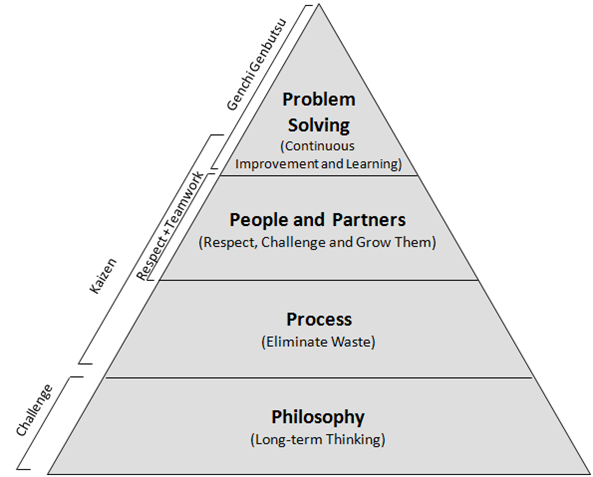

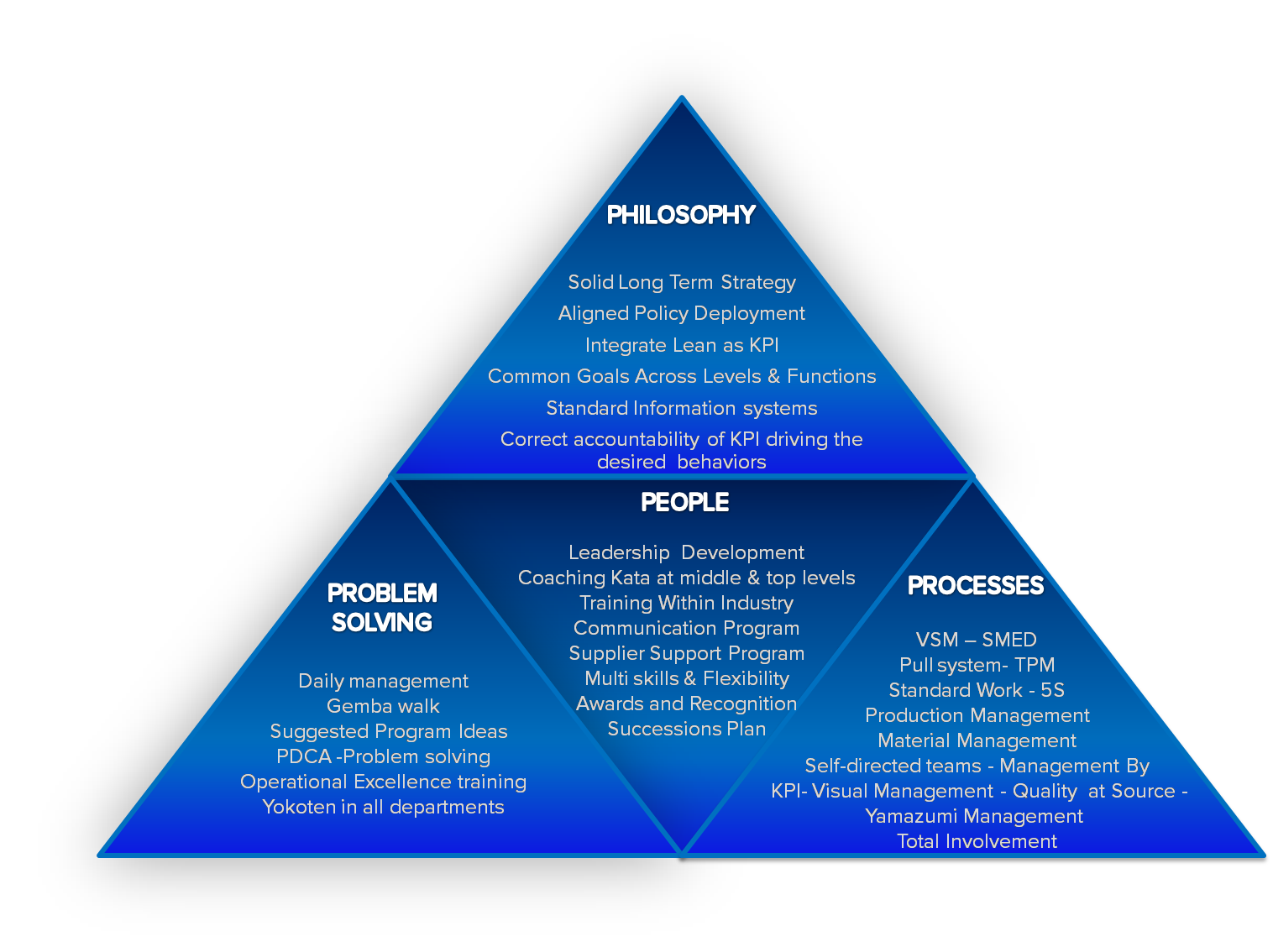

Our Lean Transformation Model

We help our customers in their journey with our Lean transformation model which is based in the Toyota Way defined by PhD. Jeffrey K. Liker in his books series.

What is the Toyota Way? A philosophy of running a business based on developing and challenging people to continuously improve, also known as Lean.

The Model is also known as 4Ps Model, which contains 14 Principles of Management, describing step by step the components of Lean management system.

This approach aims to achieve a long term sustainable culture of continuous learning and improvement.

The Toyota Way – The 4Ps

“Base management decisions on a long term philosophy, even at the expense of short term financial goals.”

Category description:

Why is a Long-Term Philosophy the Foundation?

Toyota is serious about long term thinking. The focus from the very top of the company is to add value to customers and society. This drives a long-term approach to building a learning organization, one that can adapt to changes in the environment and survive as a productive organization. Without this foundation, none of the investments Toyota makes in continuous improvement and learning would be possible.

“The right Process will produce the Right Results”

Category description:

- Toyota is a process-oriented company. They have learned through experience what processes work, reaching toward the ideal of one piece flow. Flow is the key to achieving the best quality at the lowest cost with high safety and morale. At Toyota this process focus is built into the company’s DNA, and managers believe in their hearts that using the right process will lead to the results they desire.

“Add Value to the organization by Developing your People and Partners. “

Category description:

- Create a strong, stable culture in which company values and beliefs are widely shared and lived out over a period of many years.

- Use cross-functional teams to improve quality and productivity and enhance flow by solving difficult technical problems. Empowerment occurs when people use the company’s tools to improve the company.

- Make an ongoing effort to teach individuals how to work together as teams toward common goals. Teamwork is something that has to be learned.

- Culture cannot be copied; People are your only appreciating assets!

- The Value of People is in their creativity, passion, and commitment to the business.

“Continuous Improvement and Learning “

Category description:

- Solving root Problems Drives Organizational Learning. The highest level of the Toyota Way is organizational learning. Identifying root causes of problems and preventing them form occurring is the focus of Toyota’s continuous learning system. Tough analysis, reflection, and communication of lessons learned are central to improvement as is the discipline to standardize the best-known way.

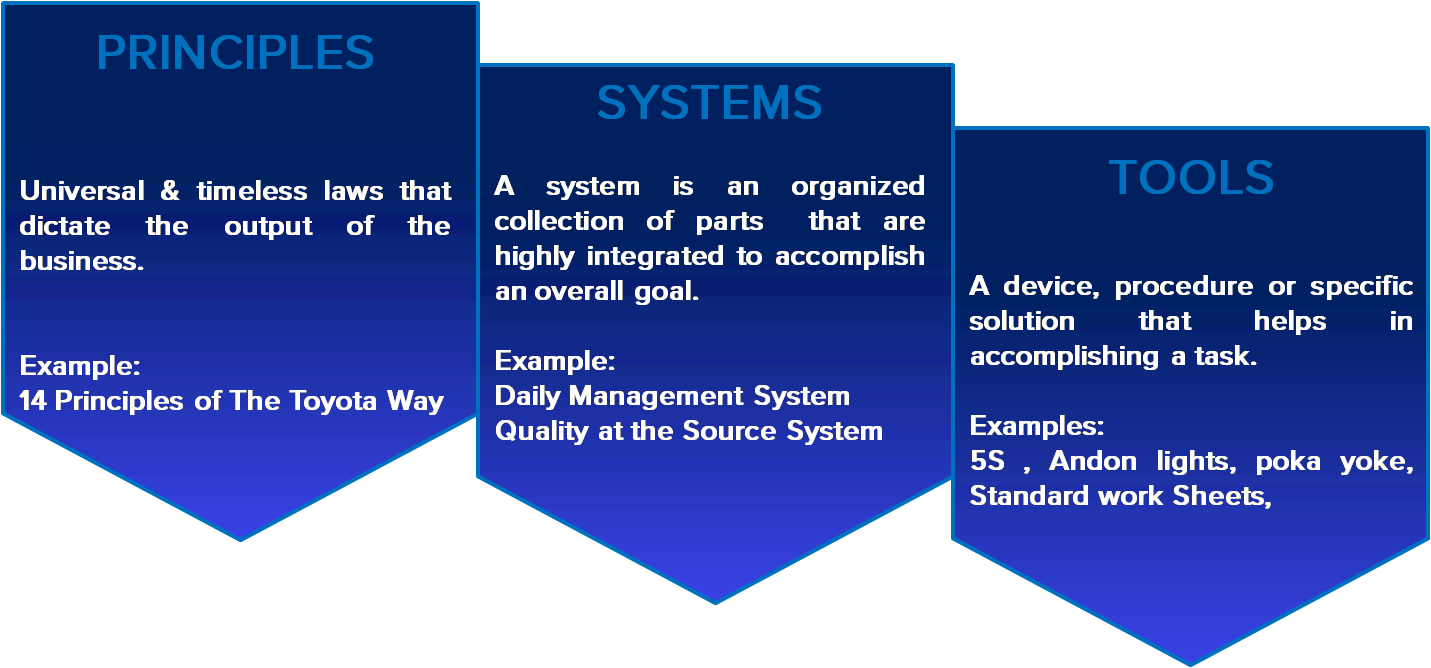

Why don’t more firms get to lean as a system?

- View lean only as a technical “toolkit”

- Focus on only short-term results

- Fail to develop people at all levels

- Move to fast-skim the surface

- Weak leadership direction

ALL THESE WEAKNESSES POINTS TO MANAGEMENT ISSUES!

Good Systems Drive Good Behaviors

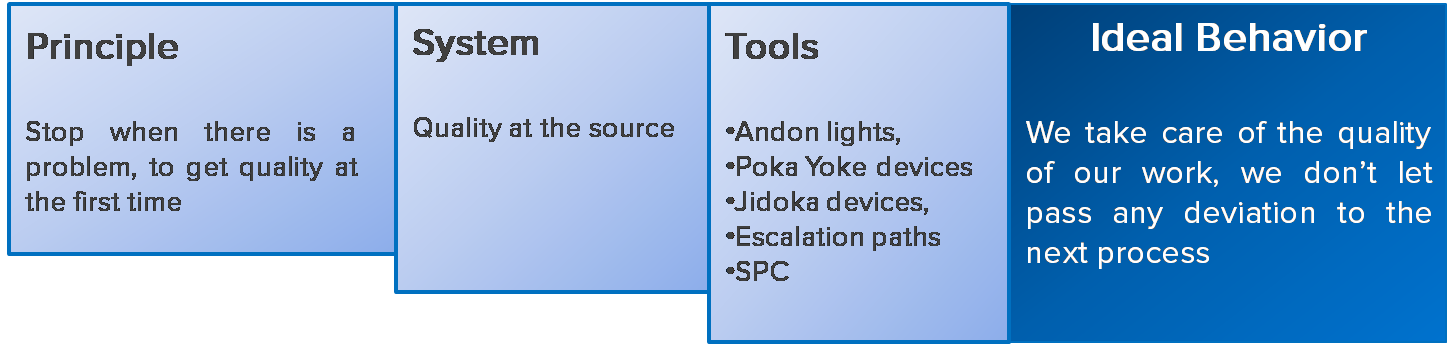

Principles are the basis to design systems that will drive associates behavior which at the end will shape the organizational culture.

In this simple example, if we want our people take care about Quality (see desired behavior) we need to establish the right systems and tools, that will enable this behavior.

It is absurd to ask frontline workers to care about quality, safety & cost, when they are only evaluated & awarded by the number of units produced.

Lean Enterprise structure, where should we focus ?

Senior Leadership

DEFINE THE IDEAL BEHAVIORS FOR THE COMPANY

Middle Management

MANAGES THE SYSTEMS THAT DRIVE BEHAVIORS

Frontline Associates

THE USE OF TOOLS ENABLE THE DESIRED BEHAVIORS

CONTACT US

RECEIVE MORE DOCUMENTATION ABOUT OUR MODEL

Do you want to know more about it?

SCHEDULE A CALL WITH OUR CONSULTING TEAM