Lean Management Assessment

The Toyota Way – Journey to True North

THE LEAN JOURNEY

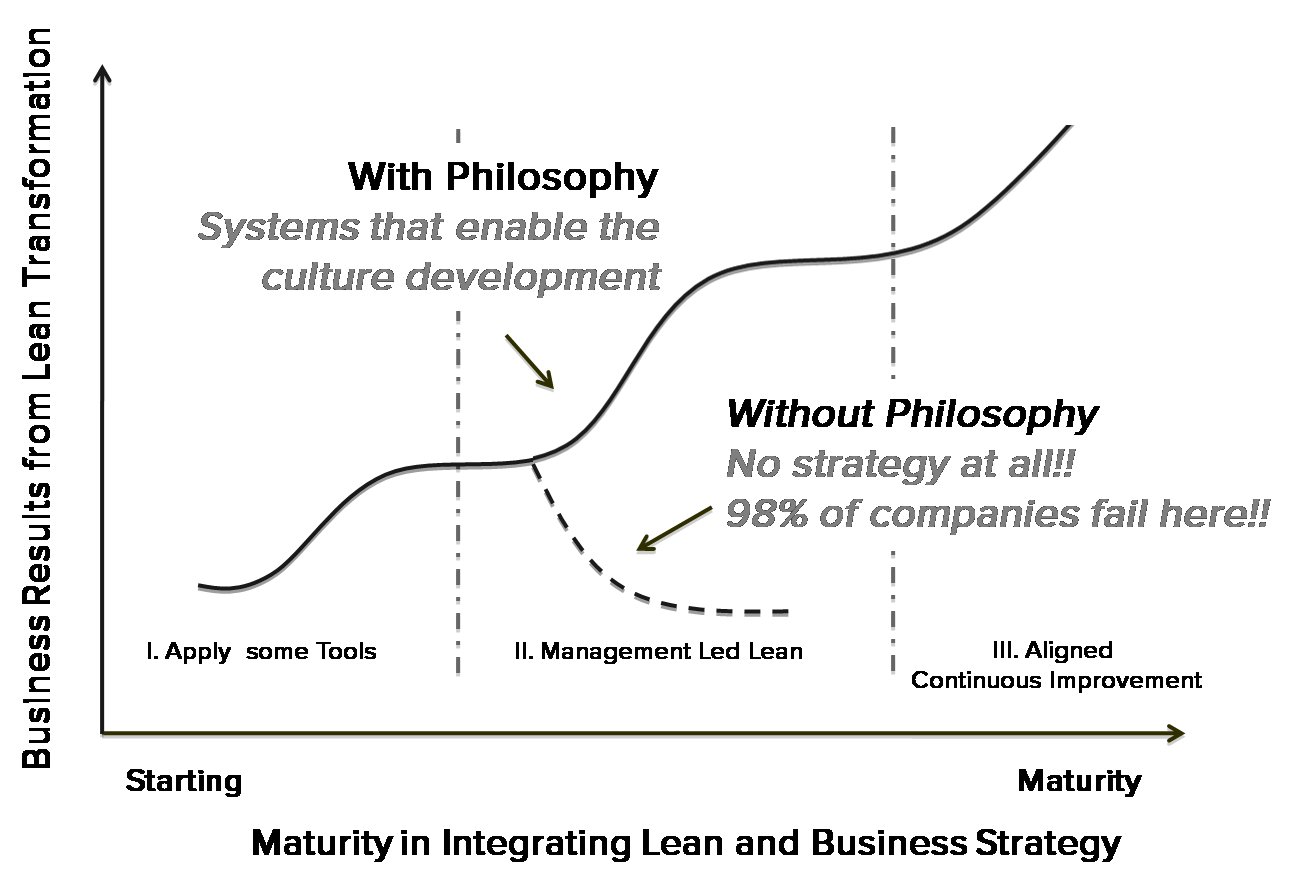

After thirty years of experience with lean programs, originally modeled after the Toyota Production System, there are many victories to celebrate with stunning results, but also much disappointment. The victories typically come from individual projects which have “leaned out” processes reducing Inventory, freeing up floor space, increasing productivity, improving quality, and improving on-time delivery to customers. The disappointment comes from the failure to sustain the new lean processes that show so much promise.

We also have seen many individual plants, and in rare cases whole companies, which have gone farther than isolated success stories. In these cases we always find exceptional leaders at the top with a deep commitment to developing people and culture to achieve sustained excellence, using lean principles.

ABOUT THE ASSESSMENT

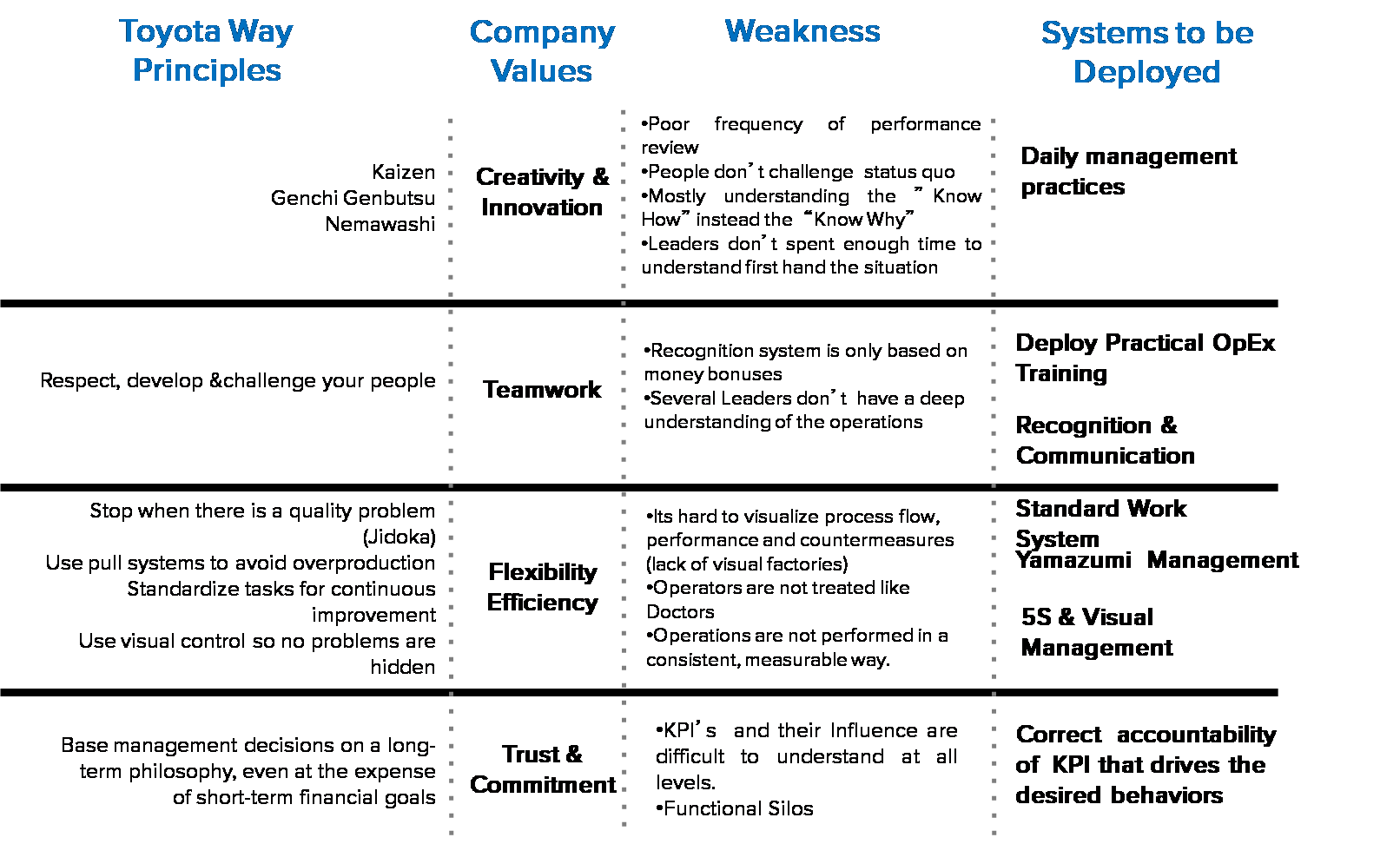

One of the first steps in moving from expert-driven lean tools to building a Lean culture of continuous excellence is to understand the gaps between where you are and where you could be. This requires a vision and a realistic assessment of your current reality.

The assessment we have designed focuses holistically on what we call the 4P model:

- Philosophy (long-term thinking toward a vision of excellence

- Processes (stable, consistent delivery of what the customer wants when they want it)

- People (respected and developed to become process improvers achieving challenging objectives)

- Problem Solving (through Plan-Do-Check-Act innovating toward a vision of excellence)

THE TOYOTA WAY ASSESSMENT STEPS:

-

1) PRE-WORK:

We review the company/site background, results from the last 3 years and its future objectives.

-

2) ASSESSMENT DEPLOYMENT FOR THE 4P’S :

We look for evidence across the organization (all levels and functions) for established systems and tools and the resulting behaviors from this.

-

3) WEAKNESSES & STRENGTHS ANALYSIS:

According to the Toyota Way model, we then analyze the gaps and advantages that the own site has, from here we will start our roadmap development

-

4) ASSESSMENT REPORT:

A deep & detailed written report about the findings of the assessment, categorized by principles and systems, explaining the reasons of the Weaknesses and Strengths.

-

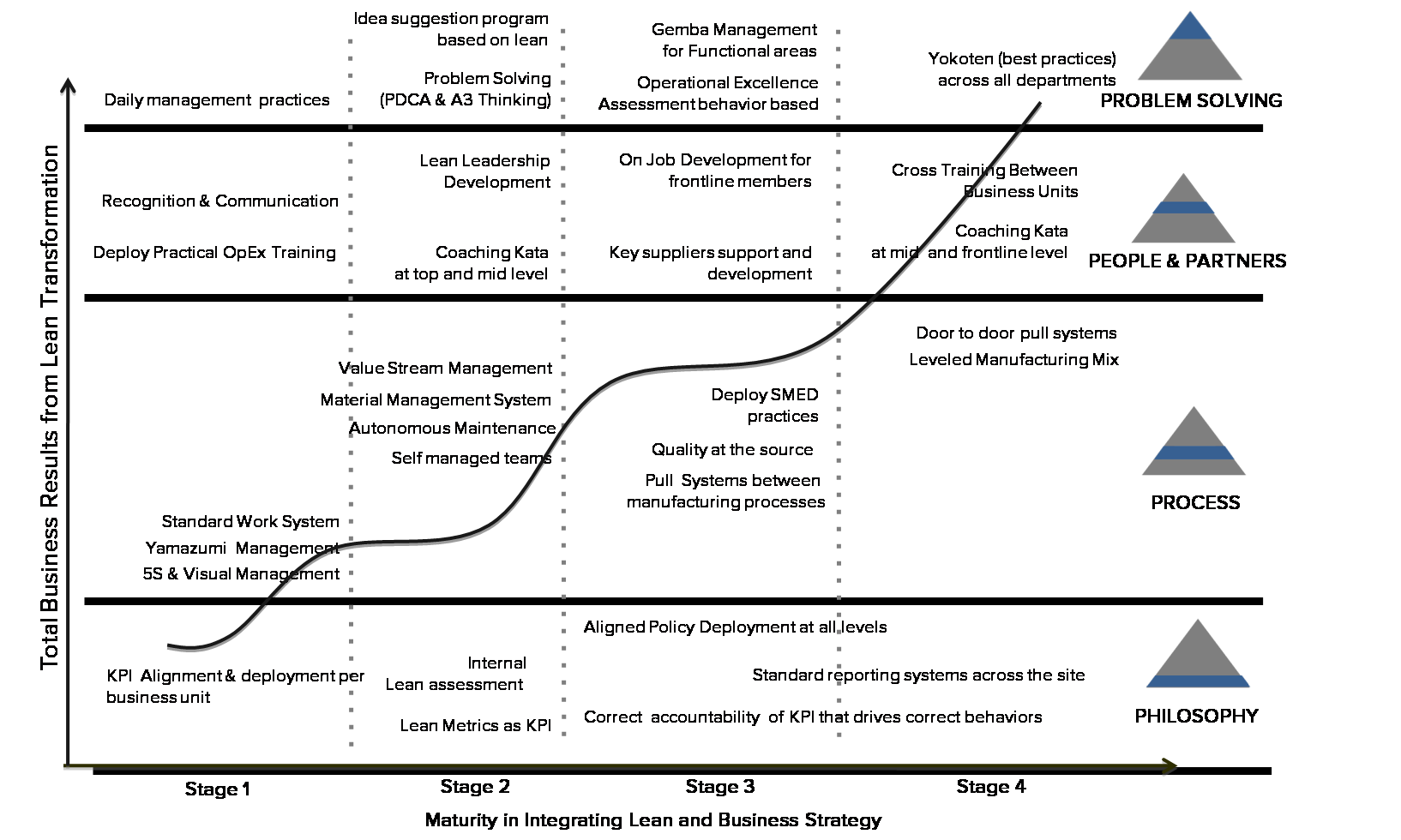

5) TRANSFORMATION ROADMAP

One of the most important deliveries of this work is the Proposed Roadmap to start or aligned the lean journey to the current company efforts; we provide the guidance for the first stage of implementation with a more detailed plan.

Together the 4Ps made up a dynamic, adaptable organization. This Lean assessment, based on the holistic model, will reveal gaps between where you are and where you want to be.

We also include specific recommendations, and, if desired, training to facilitate your journey. The assessment is against a vision of an excellent learning enterprise. It requires senior management commitment who passionately believes in this vision. We can help crystallize this vision and the steps needed to get there.

WHY AN OPERATIONAL ASSESSMENT?

Successful companies understand that improvement & innovation require a strategic compass that will drive & align all the efforts to build a sustainable structure, otherwise isolated initiatives are not going to last with the normal dynamics of the business.

Policies, procedures and documents, are important but don’t describe the real situation of a company, we grasp the actual situation of the enterprise’s culture, based on employee’s behaviors in specific factors (this cannot be pretend of fake). Then you will understand which systems must be implemented in order to enable the desired behavior from the associates.

The final deliverable is a tailored Strategic Roadmap for your company to start/revamp a cultural transformation journey and understanding the beneficiilor potențiale (culturale și financiare) potential benefits (cultural and financial) in the short and long term.

CONTACT US

RECEIVE A CASE EXAMPLE FROM A REAL ASSESSMENT

DO YOU WANT TO KNOW MORE ABOUT IT?

SCHEDULE A CALL WITH OUR CONSULTING TEAM.