LEAN STRATEGY DEPLOYMENT

DEVELOP THE STRATEGY FOR YOUR COMPANY

Objective

This program aims to explain participants the key factors for a successful lean transformation, the work structure and deployment strategy for the initial phase of a lean transformation based in the Toyota Way Model, explaining which systems & triggers must be developed and deployed, and how to measure the deployment based on behaviors, which will deliver good process and results in soft and hard benefits.

Workshop Highlights:

- Highly dynamic with discussion sessions of 5 Case Studies of companies from Automotive, Food, Plastics, Electronics industries.

- Complete documentation from all phases of a real company assessment, explaining the analysis and design of its transformation roadmap.

- Development of their own High level strategic Roadmap based on the Toypta Way Model

Training Lenght & Language:

16 hours (2 days) – English

Aimed to:

Top leadership levels, Functional Managers and Lean Practitioners from Manufacturing & Services Companies.

Mandatory Requirement:

Previous Lean Manufacturing Knowledge/Training

After training attendants will be able to:

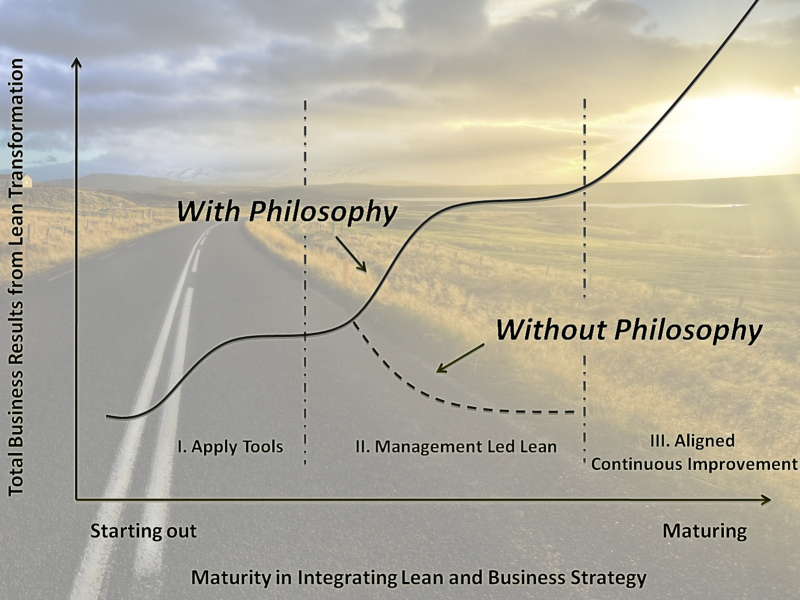

- Understanding of the Lean Transformation Model, to avoid common errors of Lean initiatives and builds on the strengths of your organization.

- Clear and comprehensive explanation (& Know How Know Why) of systems deployment in the early stages of the journey and how to measure the evolution based on behaviors

- General understanding of the lean transformation model based on the Toyota Way

HOW PARTICIPANTS RATE THIS TRAINING

INSTRUCTORS

FRANCISCO OCEJO

-Industrial and Systems Engineer graduated from Tec de Monterrey

-ALFRA Consulting´s General Director, a company specialized in consulting and training, with the participation of Senior Consultants, researchers ¨Best Seller¨ and former Toyota´s Regional Vice-President.

-Former Lean Manufacturing Manager for Celestica in Reynosa, Mexico. A company with 250 million in sales annually.

-Former WCM Leader for Celestica in Monterrey, Mexico. A company with 1 billion in sales annually.

– Trained over 5000 people in Lean Manufacturing.

– Has certified to the IIE, USA over 300 Engineers, Managers and Directors.

-Key consulting Knowledge in Lean Manufacturing- Six-Sigma- TOC – Strategic Planning.

-Certified Black Belt certified by the IIE Atlanta, Georgia, USA.

-RE-Certified by the IIE Atlanta, Georgia, USA.

–Knowledge in the Shingo Prize Model.

-Current Senior Lean Consultant Transformation in large companies which are implementing cultural change through the Toyota Way.

-Have conducted Strategic Planning Studies at the University of Essex, England.

EDGAR CARDENAS

• Examiner and co-developer of the Toyota Way Assessment Model for the True North.

• I have helped companies from different countries to develop their long term strategies to transform into a Lean enterprise delivering turnover results.

• I have trained & coached in Lean Thinking over 800 executives, managers and engineers around the world to develop their soft and hard skills.

• Experienced in management advisory for Lean Systems deployment with depth knowledge in Operational Excellence models.

Experiece with Coaching & Improvement Kata

• Development Leader for the Lean E- Training platform and Lean Simulation Materials

• I have participated as speaker and workshop facilitator for several operational excellence conferences and summits.

• In my work experience I’ve received training & coaching from different Influencers and Industry leaders like Jeffrey Liker, Gary Convis, Ritsuo Shingo, among other great colleagues from whom I’ve received great and valuable insights and experience.

TRAINING AGENDA: BODY OF KNOWLEDGE

- Lean as cultural based system

- Common reasons of Lean Strategy Failures

- Lean Architecture: Principles, Systems & Tools

- Systems Drives Behaviors

- Develop your system based in good principles

- Living the values of the company with the correct behaviors

- Leadership role in a lean transformation

Overview of Toyota Way Model: 4Ps

- Philosophy

- Process

- People & Partners

- Problem Solving

- Common Weaknesses in a Traditional Culture

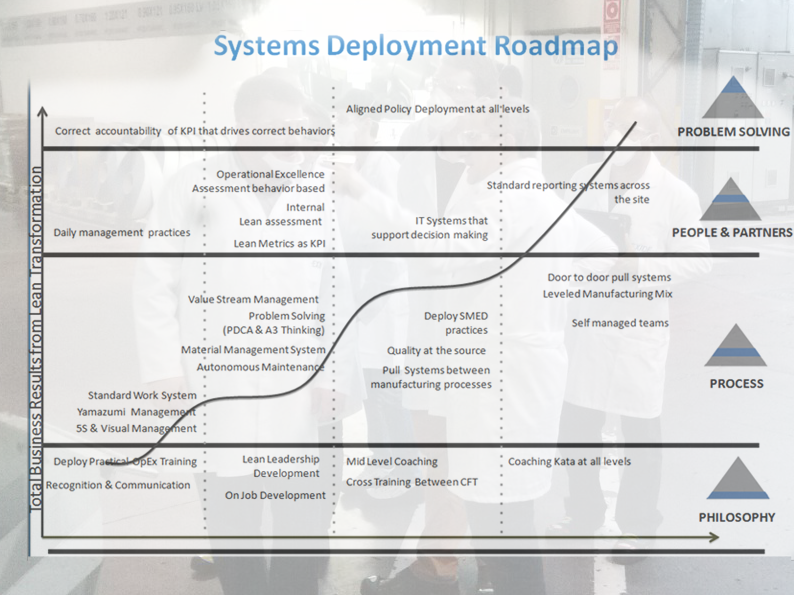

- Transformation Roadmap Examples

- Work Structure for Systems deployment

- Measuring the evolution of a Lean transformation

Analysis (Strengths, Weaknesses, Roadmap) and Discussion of Cases Studies

- “JoyFoods” Case: Living in the Comfort zone

- “ELK Solutions” Case: A Cosmopolitan Culture

- “Quadtech” Case: Too many Captains for one Ship

- “Randall” Case: The real price of a low cost operation

- “MasterMolds” Case: The MVP Quarterback ¿and where’s the Team?

Lean Systems deployment explanation:

Philosophy:

- Correct accountability of KPI that drives correct behaviors

- Daily management system

Process:

- 5s and visual management

- Standard Work

People and Partners:

- Development & training at all levels

- Recognition & communication system

Problem Solving:

- Kaizen Thinking

- Quality at the source

- Best practices among enterprise