Making Materials Flow

While manufacturing efficiency is important, it doesn’t stand-alone, one of the keys to Lean’s success is the role that Production Planning and Control plays in the organization.

The voice of the customer must be clear and consistent through the manufacturing flow, communication from the Customer, Suppliers, Manufacturing, and Engineering is key for success.

Objective

To create a model where stocking and transportation of material are reduced, by defining working methods to create a controlled and smoothed flow of materials (Kanban).

A multifunctional team will be defined from the following functions: Production Control & Logistics, Manufacturing, Engineering, C. Improvement.

- Elimination of stock areas, (WIP levels, manipulation and space reduction)

- Process lead time improvement

- Development of a pull system to reduce planning and let the manufacturing team manage the workflow

- Reduction of handling labor (forklift)

Case Examples

Learn the concepts from examples, group exercises and trainers’ experience.

Guidelines for Implementation

Guidelines for your own Implementation

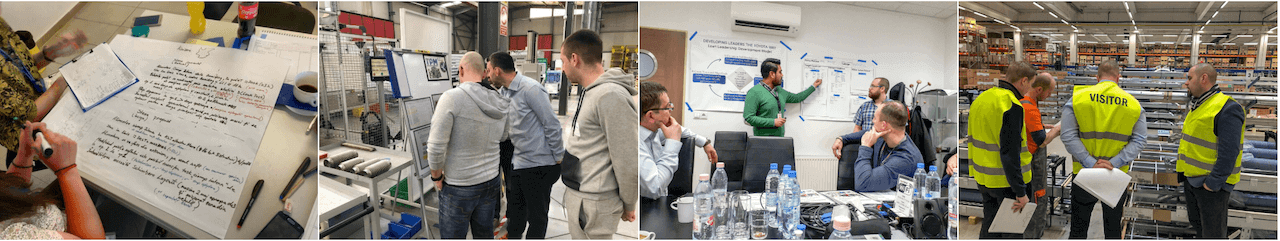

Applications on Shop Floor

Activities performed directly in the process area

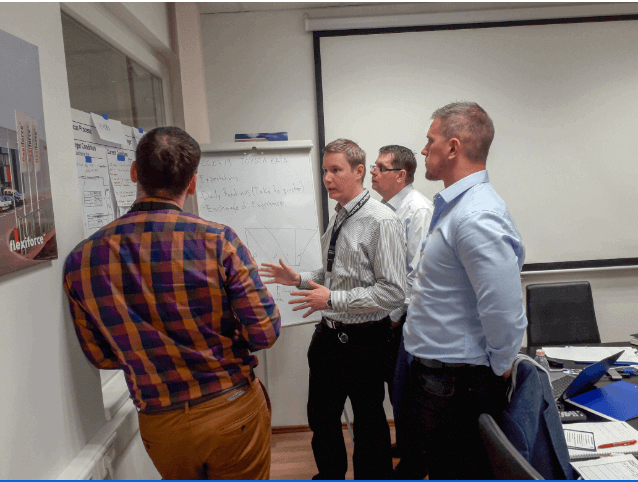

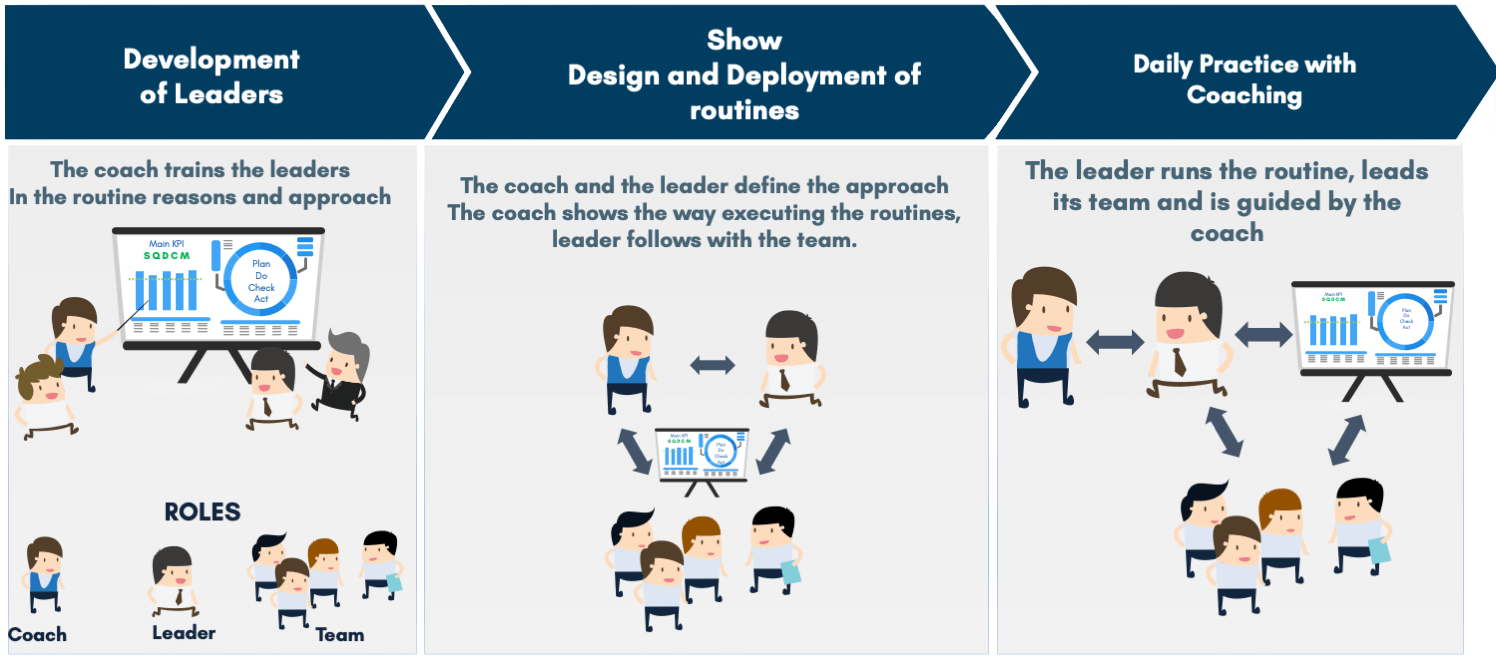

Team development Approach > I do, We do, You do

Instructed by seasoned Lean Coaches

Nicolae Gligor

Lean Management Senior Consultant

Nicolae has over 25 years of successful experience in different industries: Automotive, Chemicals, Automation & Electronics, Aerospace, leading the implementation of green field sites.

Set the foundation for a Continuous Improvement culture and led Problem Solving projects of complex business issues across multiple sites in Europe, North America, Australia and Asia.

He had roles such as Senior Quality Manager, Global Quality Improvement Manager, Lean Deployment Specialist, Business Excellence Leader, Senior Project Manager and Industrial Performance Leader for Dacia, Honeywell and Renault-Nissan.

- Responsible for the Alignment of the Honeywell Operating System at global level, Nicolae supported the global deployment of the Honeywell Production System “Order to Cash” across all Strategic Business Groups.

- Lead spin-off projects which transferred production facilities and distribution centers involving sites in UK, Germany, Italy, Romania and Czech Republic.

- Former Senior Quality Manager of Dacia Power rain & Transmission Sites, leading a quality team of 260 members, awarded as best Power-Train site of Renault’s Mecanique Group for quality performance.

- At Renault-Nissan he led Tiger Teams in site departments of Energy Saving, Maintenance, Cutting Tools and Industrial Liquids by using Digital tools and Industry 4.0 approaches.

- Supported deployment of Build in Quality concept and approach, as Subject Matter Expert, across Transportation System Business Group impacting reduction of cycle time, non-added value and cost of poor quality.

- Certified as Six Sigma Black Belt, Lean Expert, Train the trainer, VDA and IATF

- He led “Excellence Certifications” processes in USA, EMEA and APAC manufacturing and distribution site for over 40 locations.

- MBA Professional Certificate in Management & MSc degree in Automotive Engineering – University of Pitesti, Romania

Edgar Cardenas

Lean Advisor & Coach – Europe Operations Director

Edgar has worked the last years in countries like Romania, Hungary, Russia, Mexico, Colombia, Spain, and USA…, providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes, in several industries including Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, among others.

He recently provide support to companies like Bosch, Hino Motors, Mercedes Benz, Kimball, Zebra technologies, Takata, Inteva Products, Dawn Foods, BOA, Mars, Rubbermaid, Faist Group, Emerson, Exide, Harsha Engineers, Steelcase..

- Lean for Business Processes corporate trainer for several companies

- Operational Excellence speaker at several international Lean Conferences & Summits.

- He has developed in Lean Management over 1000 managers & leaders

- Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta , Georgia.

- Edgar has received direct coaching and professional development from renowned leaders like:, Ritsuo Shingo (Former Toyota President ), PhD. Jeffrey Liker (The Toyota Way), Gary Convis (Former VP at Toyota N.A. )