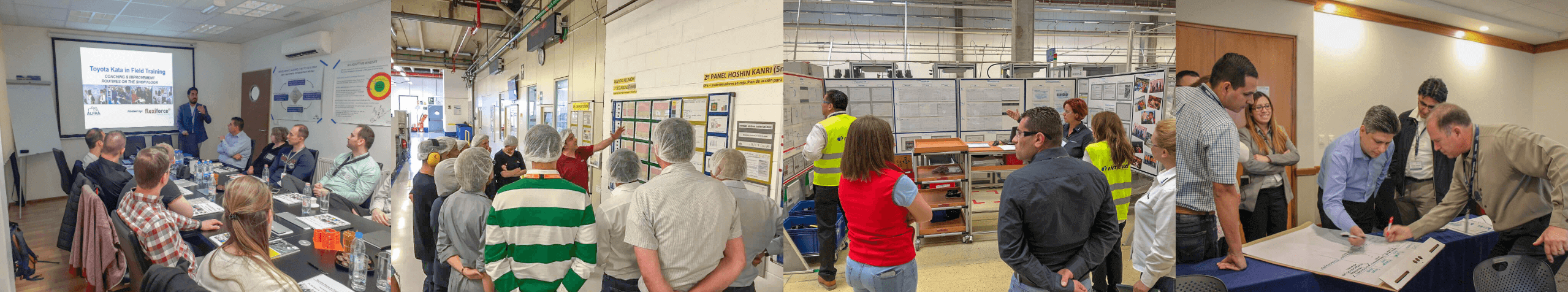

Industrial Engineering Training

System Management & Process Optimization in the Industrial Engineering Development

The industrial engineering function is in charge of developing better ways to perform work, providing support to areas like management, manufacturing, logistics, health systems and ergonomics. These 3 days workshop is a practical way to present the core elements that the industrial engineer function must fully understand to be able to support the organization.

Expected Outcomes:

IE Concepts

Learn the industrial engineering concepts and methods like ergonomics, time management, manufacturing design.

Practical Knowledge

Learn how to use the knowledge on their daily tasks, design ergonomic workflows and evaluate their efficiency.

Process Improvement

Learn how to design an assembly process and how to develop it into an

efficient manufacturing system.

Who should attend?

Leaders, Manufacturing Leaders, Production managers, Engineers, Lean Managers..

Why participate:

-

to use the knowledge on their daily tasks, being able to design ergonomic & safe work flows, optimized layout & materials flow (transport and floor space), and evaluate their efficiency.

-

Learn by doing: Alignment of the organization’s goals and activities both vertically and horizontally to drive the desire behaviors.

- Learn IE concepts and methods in a practical way,

- Learn how to design an assembly process and how to develop it into an efficient assembly system.

- Participants will be able to use the knowledge on their daily tasks, being able to design ergonomic & safe work flows, optimized layout & materials flow (transport and floor space), and evaluate their efficiency.

Industrial Engineering Body of Knowledge & Concepts:

- Design for Manufacturing & Assembly (DFMA)

- Product Life Cycle Planning (PLCP)

- Flow Oriented Layout (FOL)

- Human factors and production systems

- Relation of ergonomics and efficiency

- Ergo-check

- Methods (MTM, Stopwatch,)

- Tools

- Visualization of the workload

- Work station Design

- Assembly method optimization

- Right sequence of automatization

- Layout Comparative matrix

- Manufacturing Cost Index

- Manufacturing Optimization Workshops

- Production planning

- Routing

- Manufacturing cost calculation

Instructed by seasoned Lean Coaches

László Seres

Operational Excellence Trainer & Coach

László has deep experience in automotive industry in different countries (Germany,

Hungary, Romania..) from middle level to EMEA management position. He was responsible for supporting and establishing different functions like Industrial Engineering,

Maintenance and Operational Excellence, with focus on developing the people and teams in these areas.

- László has experience working in several countries like Hungary, Germany, Spain, Romania, Macedonia and Ukraine working for companies like BOSCH, TAKATA or Joyson Safety Systems

- He coached people in the entire organization to ensure proactive continuous improvement and problem solving attitude.

- He is the Co-founder of Lean Process Development Engineer program at University of Miskolc.

Main expertise:

- People development with Coaching & Improvement Kata method

- Problem Solving development programs & Coaching

- Supporting the implementation of TPM system

- Production system planning, Industrial engineering, Material & Information Flow management

Edgar Cardenas

Lean Advisor & Coach – Europe Operations Director

Edgar has multicultural experience (Romania, Hungary, Japan, Russia, Mexico, Colombia,

Spain, USA…) providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes, in several industries including: Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, among others.

- Edgar has lead the ALFRA European operations since 2014, developing organizations in countries like Spain, Romania, Russia, or Hungary.

- He recently provided support to companies like Bosch, Hino Motors, Mercedes Benz, Kimball, Zebra technologies, Takata, Inteva Products, Dawn Foods, BOA, Mars, Rubbermaid, Faist Group, Emerson, Exide, Harsha Engineers, Steelcase.

- Edgar is advisors for several organizations at leadership level, providing support in languages like English, Spanish and Romanian.

- Since 2014, Edgar has been developing coaches using the Toyota Kata approach, creating internal capability within the companies.

- He is an operational excellence speaker at international level Lean Conferences & Summits.

- He has developed and coached over 1000 managers & leaders in the Lean management philosophy.

- Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta , Georgia.

- Industrial Engineering & Management Bachelor Degree from Universidad Autonoma de Nuevo Leon.

- Edgar has received direct coaching and professional development from renowned leaders like: Ritsuo Shingo (Former Toyota President), PhD. Jeffrey Liker (The Toyota Way), Gary Convis (Former CEO at Toyota N.A.)

Do you want to go further? we can answer any question

Industrial Engineering, IE, process optimization, process improvement, time measurement, ergonomics training, ergocheck, Layout optimization, Layout design, MTM, motion analysis