Six Sigma Green Belt

This program was developed by experienced industry leaders to develop teams capable of identifying and executing six sigma performance projects.

This program aims to teach & mentor how to integrate principles of business, statistics, and engineering to achieve tangible results.

Developing the ability to use Six Sigma tools allow quantifying the critical issues in your company. Once the issues have been quantified, specific tools can be applied to solve the root causes and improve the current status.

Six Sigma methods increase productivity and enhance quality. As a Six Sigma green belt, you will be equipped to support and champion Six Sigma implementation in your organization.

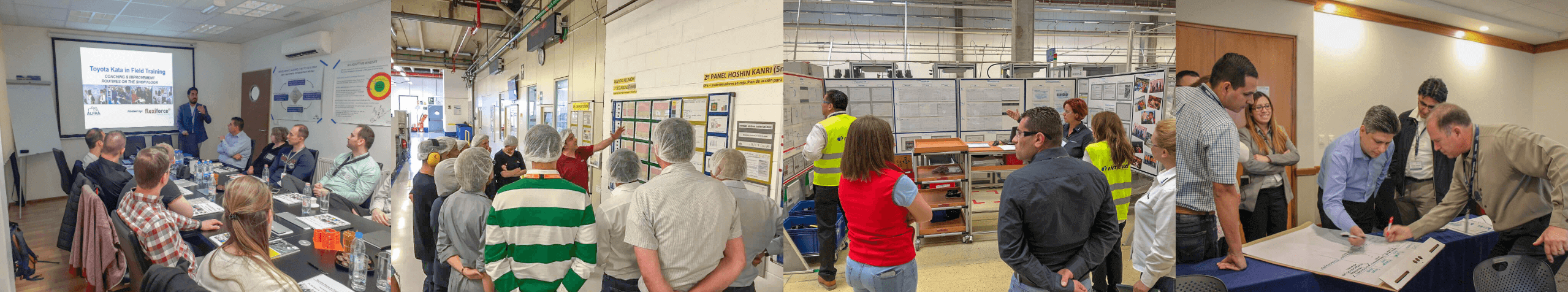

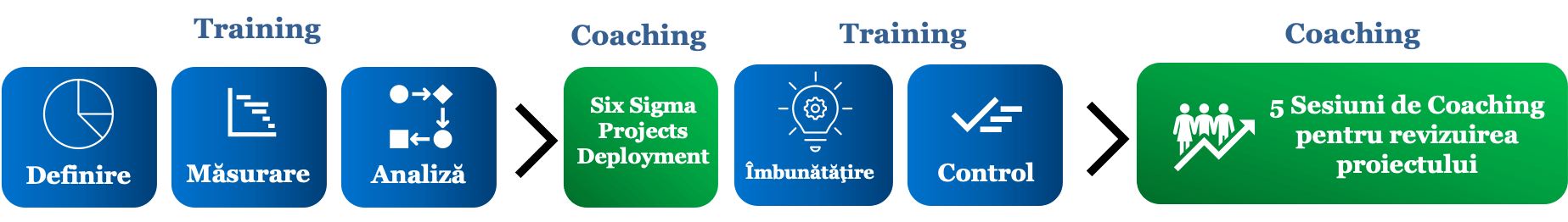

Program duration: 10 days

The proposed project must be defined before the training starts

5 days (4 days of training and 1 day of project coaching)

5 days of review of several Six Sigma complete Projects

An implementation guide for Six Sigma Projects

Participants will learn:

- The Six Sigma philosophy.

- To design and develop Lean-Six Sigma projects.

- How to calculate if a process is capable.

- To execute basic statistical analysis on process measurements.

- To employ the DMAIC process.

- To perform root cause analysis.

- How to support and champion Lean-Six Sigma tools implementation in your organization.

Six Sigma Green Belt – Body of Knowledge:

- Six Sigma Overview

- Project Definition

- Introduction to Minitab

- Statistics for Understanding and Implementing Six Sigma

- Effective Teams

- Process Mapping

- Root Cause Analysis Techniques

- Measurement Systems Analysis

- Attribute

- Variable

- Process Capability

- Graphical Data Analysis

- Cause-Effect Matrix

- Confidence Intervals

- Means

- Std. Deviation

- Proportions

- Hypothesis testing

- Means

- Std. Deviation

- Proportions

- Solution Generation Techniques

- FMEA

- Mistake Proofing

- Standard Work

- Problem Solving

- Control Methods

- Control Charts

- Attribute Control Charts

- Variable Control Charts

- Project Closure

After this training and its application participants can optionally apply for the certification process of the Institute of Industrial & Systems Engineers (IISE).

IISE is the world’s largest professional society dedicated to the support of the industrial engineering profession and individuals involved with improving quality and productivity.

Instructed by seasoned Lean Coaches

Do you want to go further? we can answer any question

5s training, 5s, 5s implementation, 5s deployment, IE, process optimization, process improvement, time measurement, ergonomics training, ergocheck, Layout optimization, Layout design, MTM, motion analysis