Lean Development Program

Inteva Products Salonta

Module 1: Lean Principles

Objective: Practical introduction of the basic elements of Lean, the Toyota Way model and the first efforts to establish a Lean production system

Downloadable files:

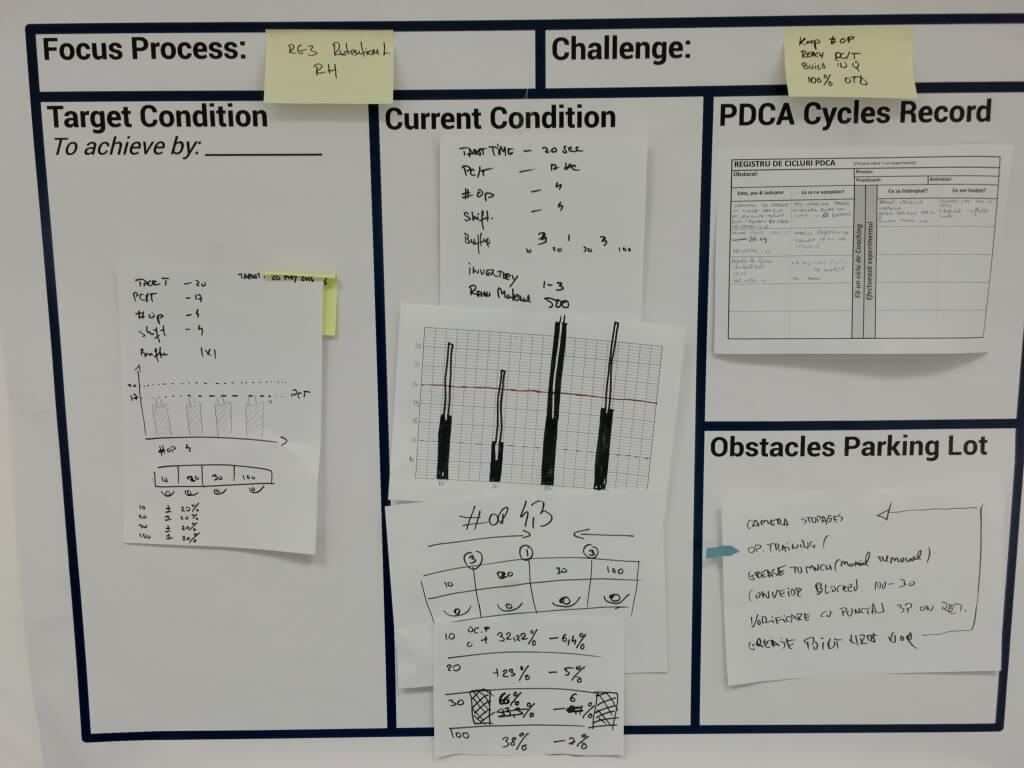

Module 2: Toyota Kata

How do you develop everyone in the organization to set strategically-aligned goals and work toward them, on time, based on the scientific method? How do you sustain this?

The Improvement Kata and Coaching Kata provides you with the answers to these questions in a comprehensive management system that enables two equally important objectives:

1.A methodology to achieve challenging objectives that are currently beyond a team’s ability to reach.

2.Developing managers and leaders as coaches for creating a culture of continuous adaptation and innovation.

Downloadable files:

Module 3: Lean Problem Solving

Objective: Continuation on the Lean development, participants will understand the systems and tools to establish more reliable and flexible processes and which requirements exists.

Downloadable files:

- Quality the source: Poka Yoke, Andon lights, Jidoka, how to assure first time quality.

- Total Productive Maintenance: Introduction to the pillars of the TPM, implementation guide and to sustain it.

- Just in Time Production and Replenishment: benefits of just in time production in inventory, space and lead time, how its support it with JIT replenishment, creating Milk runs or supermarkets.

- Principles and benefits of SMED: Concept, case example and implementation guide of quick change over.

- One Piece Flow and Small Batch approaches: explanation of continuous flow concepts, its benefits and requirements

- Cell Manufacturing and Line Balancing: Create flexible manufacturing workplace, adapt it depending on the demand level, create different scenarios of workload.

Explanation and types of the Pull Systems: how to implement pull systems depending on the process nature.

- Types of Kanban systems: calculation and implementation of Kanban signals to trigger the work.