IN FIELD TRAINING

IN FIELD TRAINING

9-11 September

9-11 September

This program aims to develop operational leaders to manage effectively daily operations and communication skills to effectively drive their teams towards continuous improvement.

This program aims to develop leaders (managers, team leaders) with deep focus in lean management and communication skills to effectively drive their teams towards continuous improvement.

Language: Romanian

Who should attend?

Leaders who want to understand how to focus on lean management and communication skills to effectively drive their teams towards continuous improvement.

Why participate:

- Develop a standard routine to improve daily management

- Problem-solving capabilities to spot and tackle abnormalities

- Build effective ways to communicate and engage their team members

- Increase on-the-job development skills to grow their teams

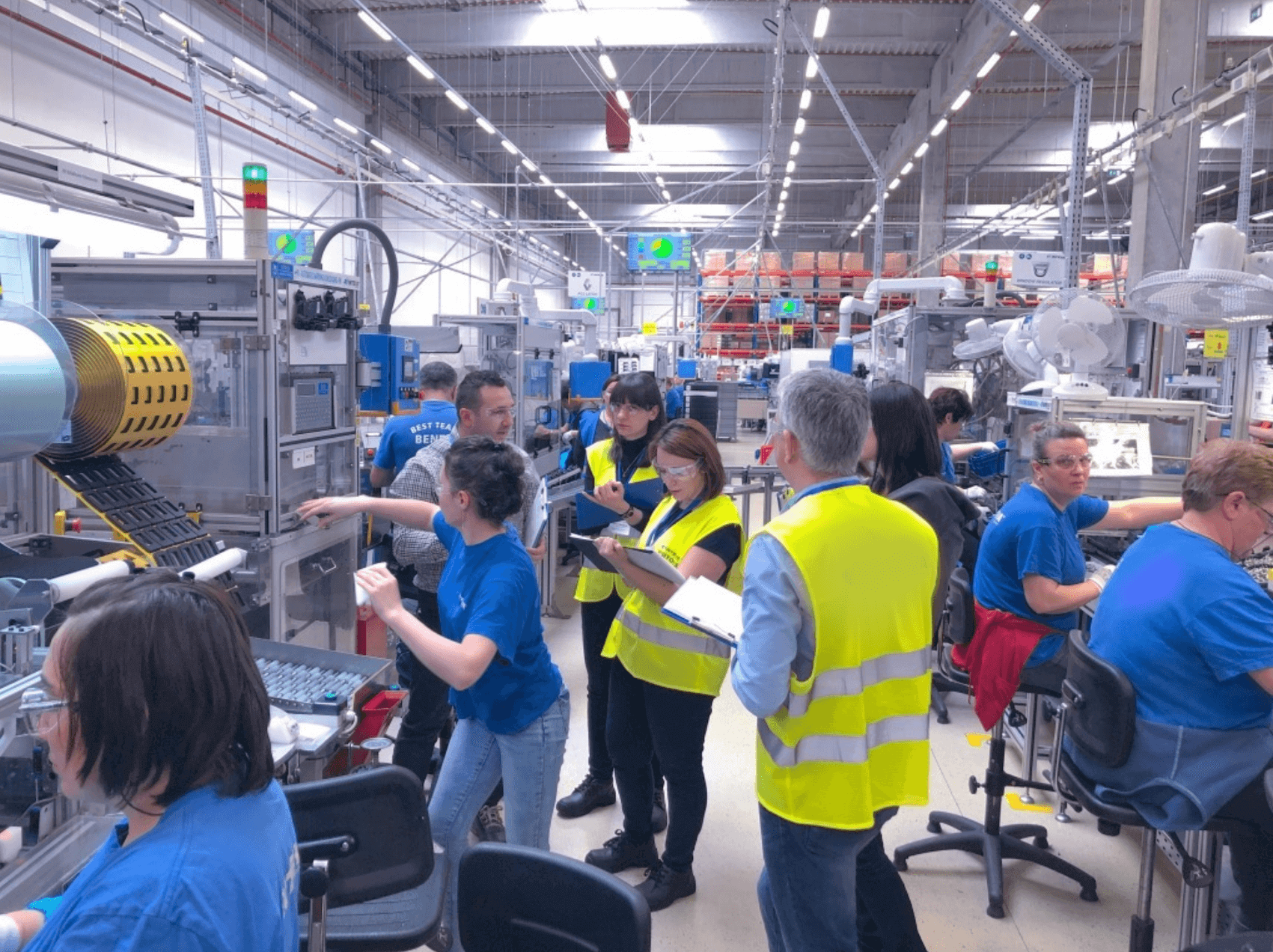

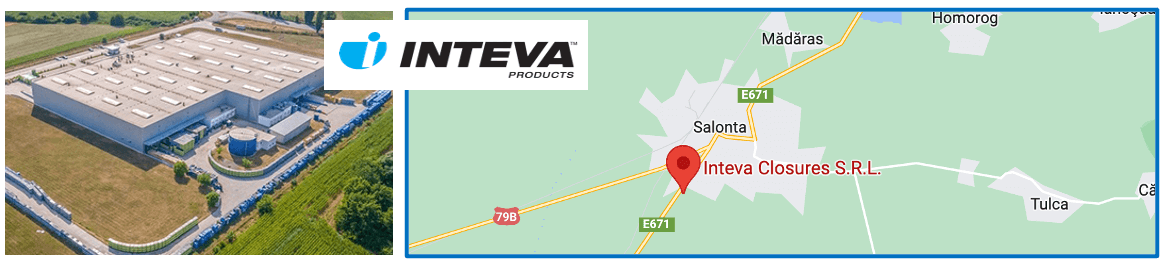

Host Plant: Inteva Products Salonta.

Data: 9-11 Septembrie 2025 – Salonta, Bihor – Inteva Products

Address: Calea Aradului, DN79 140 C, Salonta 415500, Romania

Training Team

Dan Dogojie

Lean Management Senior Consultant

Dan is a senior-level advisor with +25 years of experience in an industrial environment (automotive, electronics). He has extensive experience as plant manager for Electrolux, Autoliv, Panduit, and Delphi, responsible for operational and financial deliveries of plants.

He has experience in production plant start-ups, green-field / high–growth plant operations, crisis stabilization, task-forces operational, and general plant management.

- He was also production Director at Group Dacia-Renault Mioveni plant, responsible for car manufacturing departments operations: stamping, welding, paint shop, and car assembly. He led the production System and LEAN responsible for the EMEA region in the Autoliv airbag division, as ACE Program Manager;

- He starts applying lean manufacturing principles in the Solectron plant. More experience followed in Dacia-Renault OEM plant, by obtaining Renault Production System- black belt title as Industrial Organizer and applying RPS strategies in Mioveni plant.

- He held positions of Materials Control and Logistics Manager for Philips and BOS Automotive, with activity start-up and formation of Supply Chain & Logistics Department of BOS Automotive (green-field) for custom clearance, transportation coordination, shipping-invoicing, raw material-finished goods warehouses, material pull-systems among plant value-streams, indirect goods purchasing, production-demand-dispatch planning, material control buyers teams; start-up of 2 consolidation warehouses for raw material supply chain (located in Germany) and 2 JIT warehouses/ OEMs located in Austria and Spain.

Nicolae Gligor

Lean Management Senior Consultant

Nicolae has over 25 years of successful experience in different industries: Automotive, Chemicals, Automation & Electronics, and Aerospace. He led Problem Solving projects on complex business issues across multiple sites in Europe, North America, Australia, and Asia.

He had roles such as Senior Quality Manager, Global Quality Improvement Manager, Lean Deployment Specialist, Business Excellence Leader, Senior Project Manager, and Industrial Performance Leader for Dacia, Honeywell, and Renault-Nissan.

- Responsible for the Alignment of the Honeywell Operating System at global level, Nicolae supported the global deployment of the Honeywell Production System “Order to Cash” across all Strategic Business Groups.

- Lead spin-off projects which transferred production facilities and distribution centers involving sites in UK, Germany, Italy, Romania and Czech Republic.

- Senior Quality Manager of Dacia Powertrain & Transmission Sites, leading a quality team of 260 members, awarded as best Power-Train site of Renault’s Powertrain Group for quality performance.

- At Renault-Nissan using Industry 4.0 methods he led Tiger Teams (Clubs Métier) for all Powertrain sites and involving departments of Energy Saving, Maintenance, Cutting Tools and Industrial Liquids

- Supported deployment of Build in Quality concept and approach, as “BiQ Subject Matter Expert”, across Transportation System Business Group in Honeywell, impacting reduction of non-added value and cost of poor quality.

- He led “Excellence Certifications” processes in USA, EMEA and APAC manufacturing and distribution site for over 40 locations, using as referential the Lean and 6 Sigma tools.

Edgar Cardenas

Vice-President Global Operations

Edgar has multicultural experience (Romania, Hungary, Japan, Russia, Mexico, Colombia, Spain, USA…) providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes in different industries including, Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, Aerospace, among others

- He has provided support to companies like Bosch, Inteva Products, Scandia, Hino Motors, Kimball, Zebra technologies, Takata, Continental, Dawn Foods, BOA RBT, Mars, Rubbermaid,, Emerson, Exide, Harsha Engineers, Steelcase.

- He has worked in several industries including, Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, Aerospace, among others

- Edgar is an advisor for several organizations at the leadership level, providing support in languages like English, Spanish and Romanian.

- Since 2014, Edgar has been developing coaches using the Toyota Kata approach, creating internal capability within the companies.

- He is an operational excellence speaker at the international level of Lean Conferences & Summits.

- He has developed and coached over 1000 managers & leaders in the Lean management philosophy.

- Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta, Georgia.

Our participants review

I think that this course made an important contribution through trainers, content, and structure, also the practical examples completed the theoretical part and inspired me in what I want to implement in the company as a philosophy and good practices. The way that the scientific part was explained helped me and then the practical part through skills up to the level of attention to behaviors also. The live sessions, especially in which Mr. Cristea was invited, reinforced the message that the implementation of lean management is possible.

Thank you, in my personal name, first of all! It was very interesting for me. I admit that I am fascinated by the LEAN system and I have a curiosity and a desire to deepen my knowledge in the field.

And, implicitly, on behalf of the company. It is a very useful source of information for my colleagues.

Join us, Register Now!

- Individual AccessUntil 29 April€1200/ ParticipantReduced from 1600€

- Personal access to 6 days of training & coaching on site

- Personal access to learning platform

- Digital training material

- Personal access to Zoom meetings for training and project coaching

- Alfra Consulting training recognition