Analyze, design and select the best production process using the lean principles, save time in the launch process!

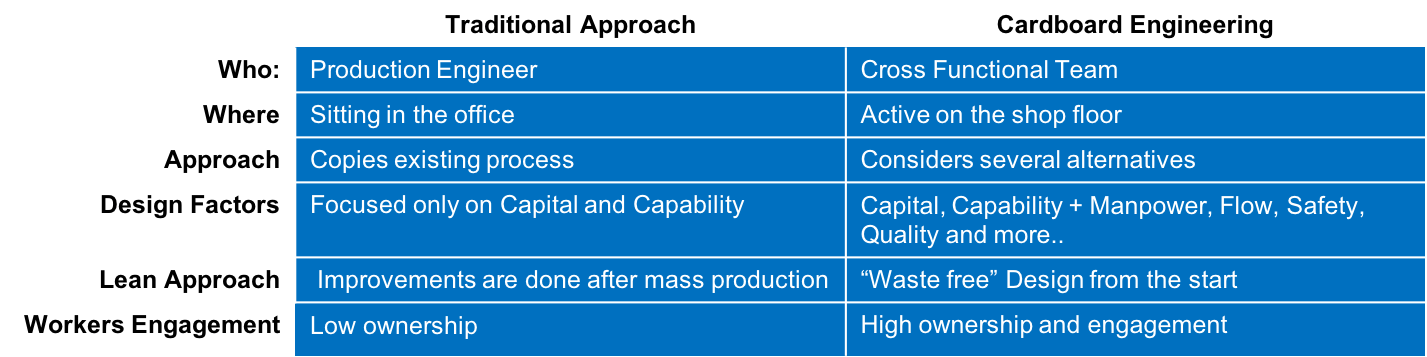

What is Cardboard engineering? A practical method to design Lean processes and flow with a 1: 1 model implemented in an industrial workplace. Eliminates costly modifications after release and start of production, this is designing a Lean process.

Expected results:

Cardboard Engineering concepts

Learn the concepts of Cardboard engineering

Practical Knowledge

Learn how to use your knowledge in everyday tasks.

Practical Exercises

Perform activities directly in the process area

Training length: 3 days (24 hrs.)

Why participate?

- Learn in a practical way how to design an optimized process flow and how to put it in an efficient assembly system.

Recommended for:

- Project and launch managers

- NPI teams

- Industrial engineering,

- Manufacturing,

- Lean practitioners

- Team members involved in the equipment design and preparation of workflows.

Methodology benefits:

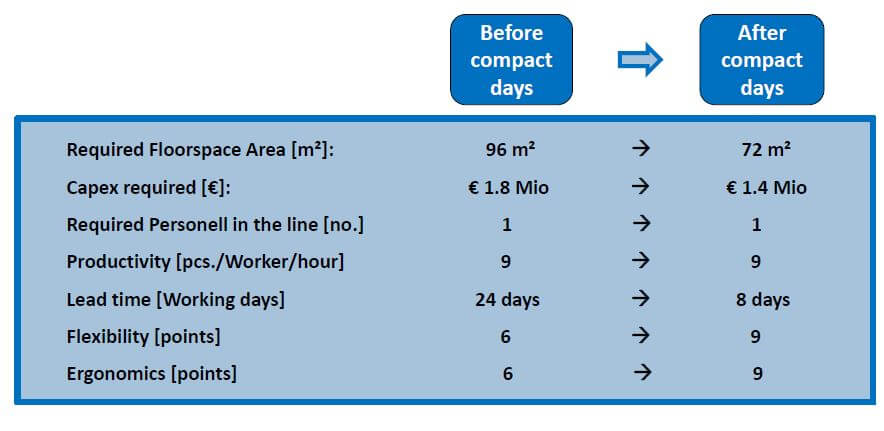

- Reduction of capital Investment ( 20%- 40% less)

- Optimized layout & material flow (transport and floor space)

- Ergonomic & Safe (avoiding Dirty, Dangerous, and Difficult)

- Flexibles for volume and product changes (takt alignment)

- Reduced lead times and inventories (WIP and buffers)

- No additional/ unplanned cost for unnecessary correction loops

- High level of motivation among employees by integrating the works of gutters and improvement

Workshop Objective:

In our 2-day-workshop participants develop the skills to optimize the value added stream, developing waste free work flows with a “hands on” process analysis.

Give the teams related with the new product development process, the opportunity to work out and simulate the best solution for a value stream, before investments are done, delivering a higher level of quality, productivity, safety and delivery at the start up.

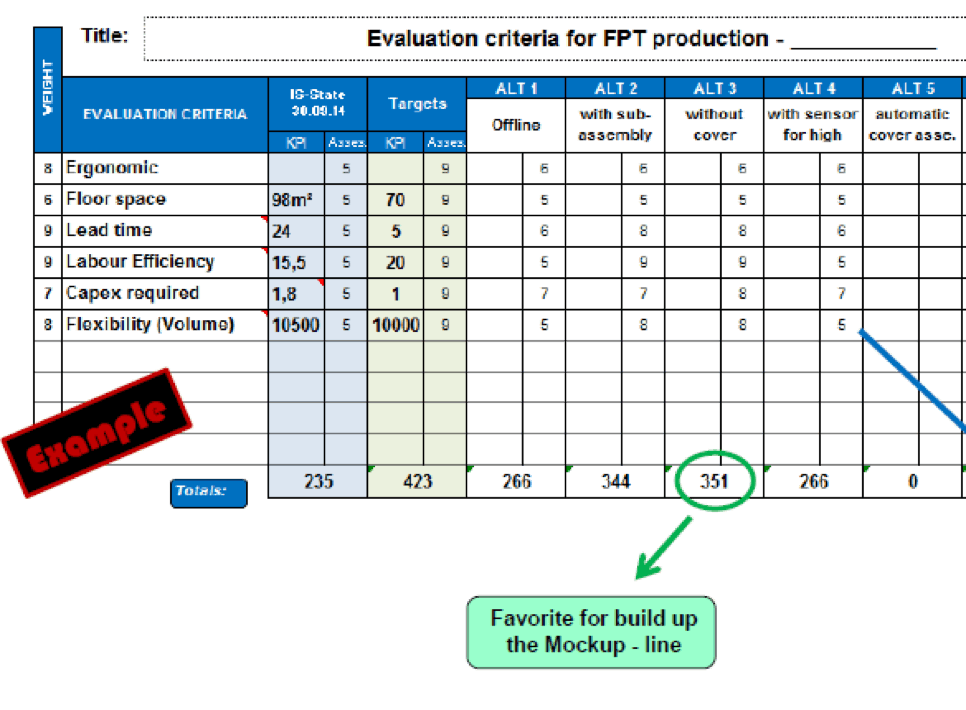

Evaluation of Proposals

Main value for participants:

- Learn in a practical way how to design an optimized process flow and how to put it in an efficient assembly system.

- Work in teams, receiving knowledge and sharing with other colleagues ideas to implemented right away in your site.

- Participants will be able to pass the knowledge on their companies, being able to design new work flows, identify potential waste sources, and evaluate their efficiency.

Cardboard Engineering Simulation

Results after workshop