Digitalization is one of the most transformative forces of our time. It’s changing how we work, live, and play in ways nobody could have predicted a few decades ago. And while it’s been slow to gain traction in some industries, digitalization has had a major impact on manufacturing. Digitalization refers to the use of computers and digital technology to transform analog information into digital information for storage, processing or transmission. The benefits of digitalization lie in the ability to make more precise calculations, control processes with precision, increase speed and efficiency, and decrease costs. Today’s manufacturing processes are becoming more digitized than ever before. If you still want to understand how this affects your industry or business, read on!

Digitalization can be defined as

the conversion of analog data into digital information

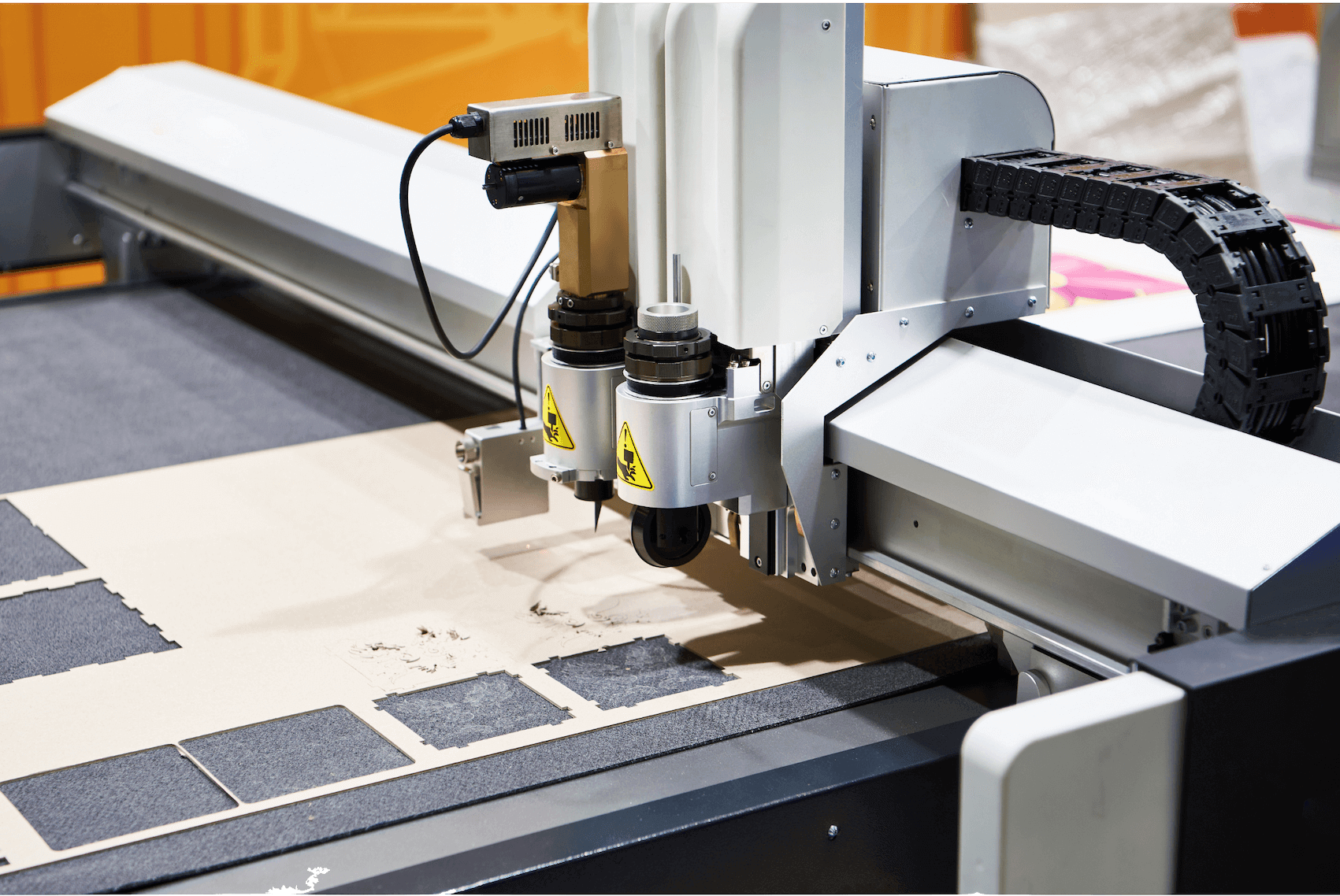

Historically, manufacturing has been done through physical processes. Nowadays, a wide range of high-tech tools are used for all aspects of production.

Another way to define digitalization is the use of computers and technology in the manufacturing process. Digital controls allow manufacturers to make more precise calculations and monitor how their products are being made with accuracy. This makes it easier to produce higher quality items faster and cheaper than ever before; all while still maintaining a reasonable level of safety.

The benefits of digitalization

Digitalization has many benefits. The primary benefit is the speed at which information can be processed. The other major benefit is the precision of calculations and control processes. The more precise you can be with your manufacturing processes, the better quality product you can produce. Imagine a virtual reality (VR) headset that provides in-depth instructions on how to assemble a home appliance or a robot that assembles products automatically. These are only two examples of digitalization in manufacturing processes, but they illustrate how digitized products are becoming more common in today’s manufacturing world. With digitalization, companies will see higher levels of efficiency and decreased costs as they are able to control their production much more precisely than ever before.

How manufacturing processes have changed

Traditional manufacturing processes are becoming more digitized as companies strive to increase production, delivery speeds, and efficiency. For example, in a traditional manufacturing process, a manufacturer would produce a product on an assembly line. This is known as mass manufacturing because it yields large quantities of products. However, this process was not very precise and was costly due to the need for human labor and time-intensive steps. With digitalization, however, manufacturers can use robotics to increase precision and control over the assembly lines while also decreasing cost by using human labor only where add value, liberating workers from repetitive, mechanical work.

In another example, production processes in the past would store data locally which made it difficult to share information or coordinate between different entities within one company. Manufacturing has traditionally been segmented when it comes to operations due to these limitations inherent in analog data storage methods like paper records.

Digitalization has created the opportunity for companies to work together more easily through shared databases that are connected electronically.

Finally, traditional manufacturing methods were limited by what could be done with analog tools like pens or pencils. Digitalization has ushered in new technologies like 3D printing that enable new possibilities for making things more efficiently than ever before. 3D printing is even being used in some medical applications today!

What do you need to know? The challenges of digitalization

The challenge of digitalization is that it’s simply not a one-size-fits-all solution. It requires logic and in-depth architecture. Depending on the size and complexity of your business, the benefits and disadvantages can vary depending on what you need to accomplish.

Here are some things you’ll want to keep in mind as you consider how digitalization will affect your manufacturing processes:

* Make sure you have the time and resources for a major undertaking – Before investing in anything, take the time to evaluate your strengths and weaknesses. What are some areas of your business that could benefit from digitalization? What would be better left untouched?

* Consider where your customers are going – As more people turn to mobile devices for their purchasing habits, speed becomes an important factor. If your customers mostly use smartphones or tablets when they buy, then this will change how you should invest in digitalization.

* Stay up-to-date with changes – The pace of change has never been so fast before. The world of digital marketing has made dramatic changes almost overnight. Stay up-to-date with changes by reading blogs and articles about the latest trends in innovation and technology; this will help to inform your decisions about where to invest or not invest in digitalization efforts.

Conclusion

Digitalization can be defined as the process of making something digital, like a manufacturing process.

Manufacturing processes have changed to a great extent from being analog to becoming digital which has resulted in the introduction of various technologies.

Digitalization has offered many benefits and advantages to the manufacturing industry but there are also some challenges that need to be addressed before it can be completely embraced by this industry.