Karakuri Kaizen Training

Developing effective workplace conditions

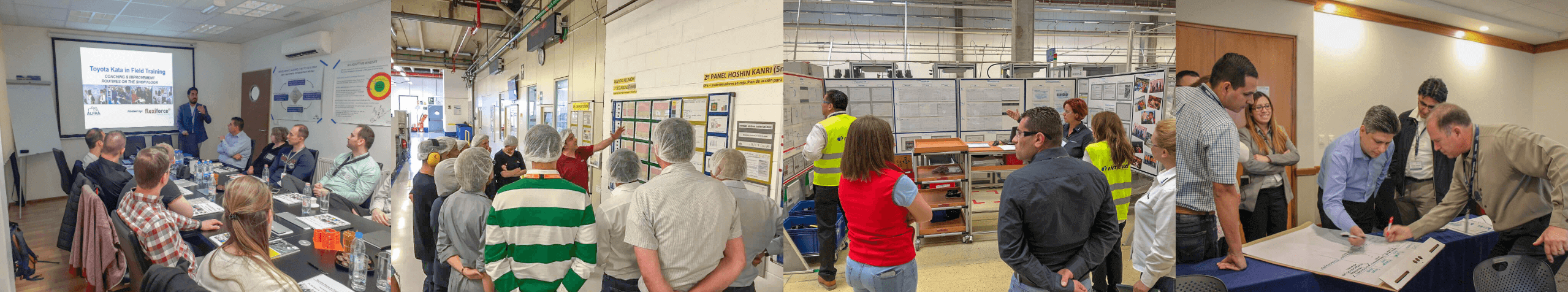

In-field Training

In our 3-day-workshop participants develop the skills to optimize the value-added stream, developing waste free workflows with a “hands on” process analysis.

Main Objective: Give the teams the opportunity to work out and simulate the best solution for a value stream, before investments are done, delivering a higher level of quality, productivity, safety and delivery at the start up.

Align & deploy actions across the organization to achieve your objectives

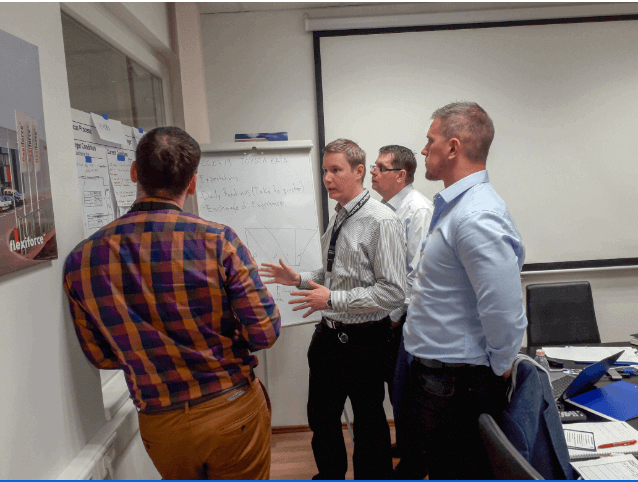

Participants will split into teams to perform activities in the shop floor and present their observations.

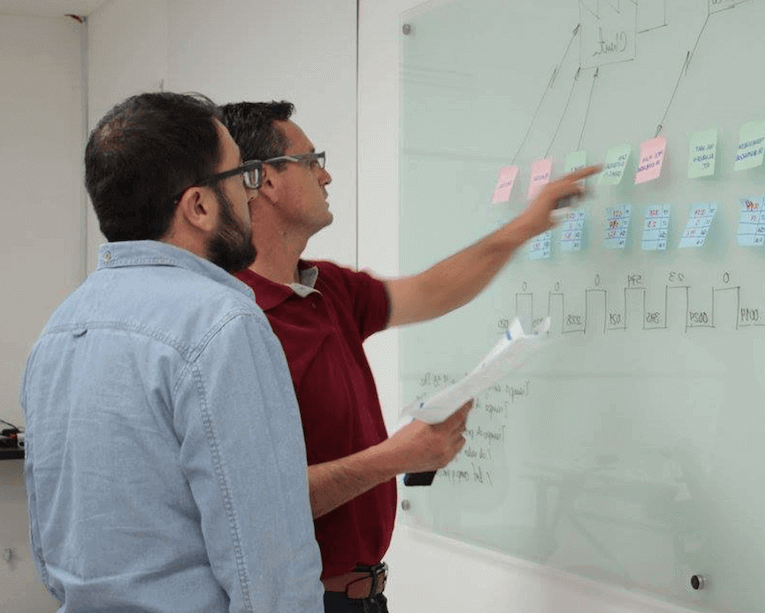

Practical Learning

Learn the concepts from Toyota examples, group exercises and trainer’s experience

Group Discussion

Share experiences with managers from different industries and background

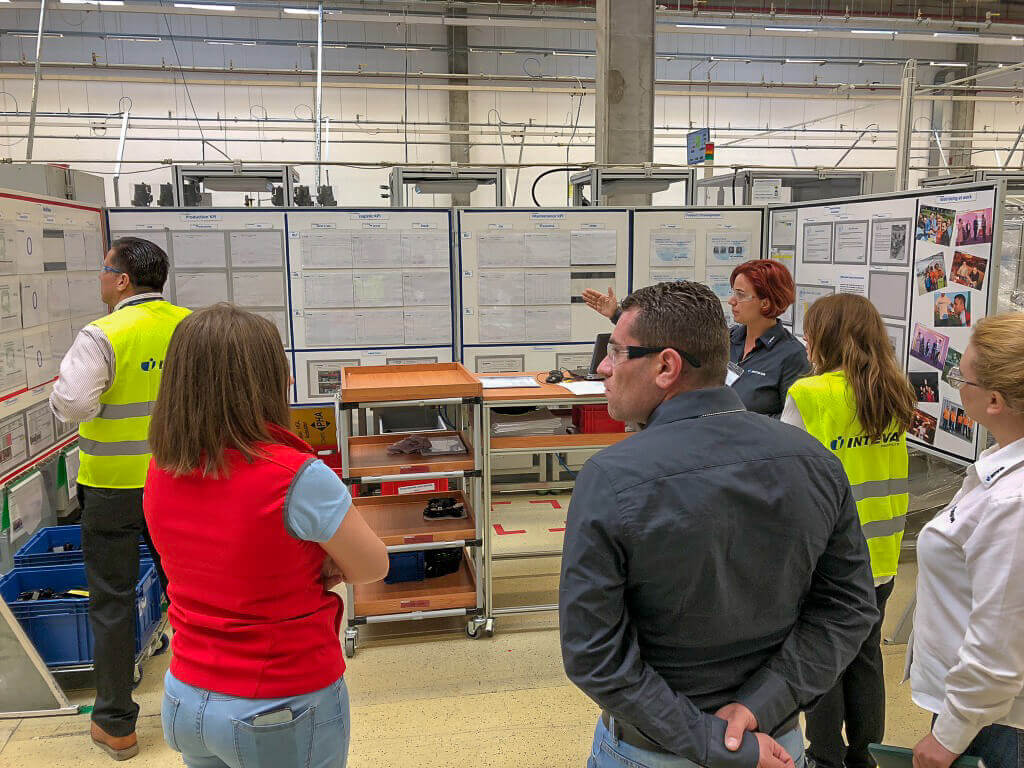

Shop Floor Exercises

The training is hosted by a factory, with activities direct in the process area

Elements of an effective Workplace

Effective workstation arrangement elements:

- Upgrade security (Safety)

- Ergonomically Efficient

- Increased quality & productivity

- Easy Maintenance

- NO Mura, Muri and Muda

Why participate:

- In our 3-day-workshop participants develop the skills to optimize the value-added stream, developing waste free workflows with a “hands on” process analysis.

Benefits from an “On-Site” Workshop:

- Exercises & real applications are focused on your own operations.

- Participants get a comprehensive understanding of the Lean Principles for Improvement.

- Build capabilities to identify opportunities and improve them.

- Gain momentum to engage your employees in the continuous improvement journey.

- Learn the method in a practical way, how to design a lean process, and how to develop it into an efficient assembly system.

- Work in teams, receiving knowledge and sharing with other colleagues ideas to implement.

- Participants will be able to pass the knowledge on to their companies, being able to design new workflows, identify potential waste sources, and evaluate their efficiency.

Training Agenda:

- Lean Principles Value Added, Waste, The 3 Reals.

- Muda Elimination.

- 5S, Standard Work & Visual management.

- Karakuri Introduction

- Karakuri principles: Creativity, Skills, Knowledge

- Ergonomics for improving productivity.

- Ergonomic Assessment and Action Plan.

- Brainstorming and first proposals of karakuri solutions.

- Workload Balancing using Yamazumi charts.

- Strike zone and other Lean principles for process design.

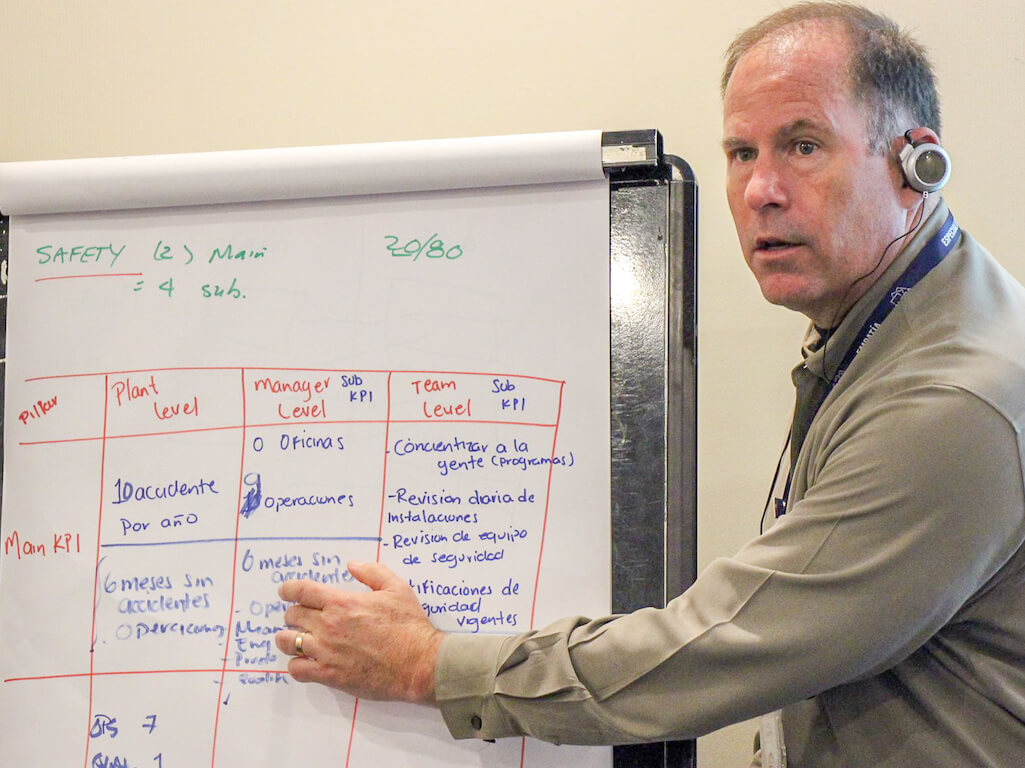

- Daily Management (daily performance review).

Instructed by seasoned Lean Coaches

Jeff Strabala

Former Toyota Manager & Operations Management Expert

Jeff worked for Toyota for over 21 years; his extensive experience is based in Operations Management in Toyota North America as Manager and internal consultant.

Jeff was member of the Leadership team for the launch of two “Greenfield” automotive plants and subsequent plant capacity expansions valued in $4.2 billion USD. During his tenure at Toyota, Jeff also spent 3 years of “internal consulting” with improvement projects at Toyota and Tier 1 suppliers.

Project General Manager (Consultant) – Toyota OMDD

- Internal consulting position, Investigation, Analysis, and Improvement of floor operations applying core Toyota Production Systems tools.

Project General Manager – Toyota North America.

- Improved Safety Systems for Toyota’s MS manufacturing plant through active initiatives to educate plant personnel revise and introduce new programs, establish management accountability through daily reporting and monthly performance meetings, introduced gated safety management process that reduced TIR by 50% within 6 months.

- Developed, Validated comprehensive [all functions] Safety Metrics during 2013 New Generation Corolla launch, resulted in improved safety KPI during launch, Metrics, tracking and reporting adopted in North American Region.

Assistant General Manager-Toyota

- Responsible for Plant Manufacturing Operations, member of Executive Team,

Primary responsibility for Production Control, Supply Chain & Logistics, Project Management for 8 Model changes, Plant Manpower Productivity planning and reporting. - Supported Toyota Production System training and application, and Visual Management (FMDS) roll out at TMMBC, management Mentor.

Manager, Production Control – Toyota (TMMBC & TMMI)

- Production Control Planning & Coordination of Operations for Toyota truck factory with multiple product lines 2000 -2003.

- Additional collateral duties involved management of TMMI Corporate Strategy and Reporting, TPS Training Group, Manpower Planning and Productivity group.

Manager Accounting & Finance, Toyota TMMI

- Started up Accounting & Finance operations for Greenfield Toyota plant in Indiana, responsible for accounting, internal and government compliance, budgeting and cost reduction efforts.

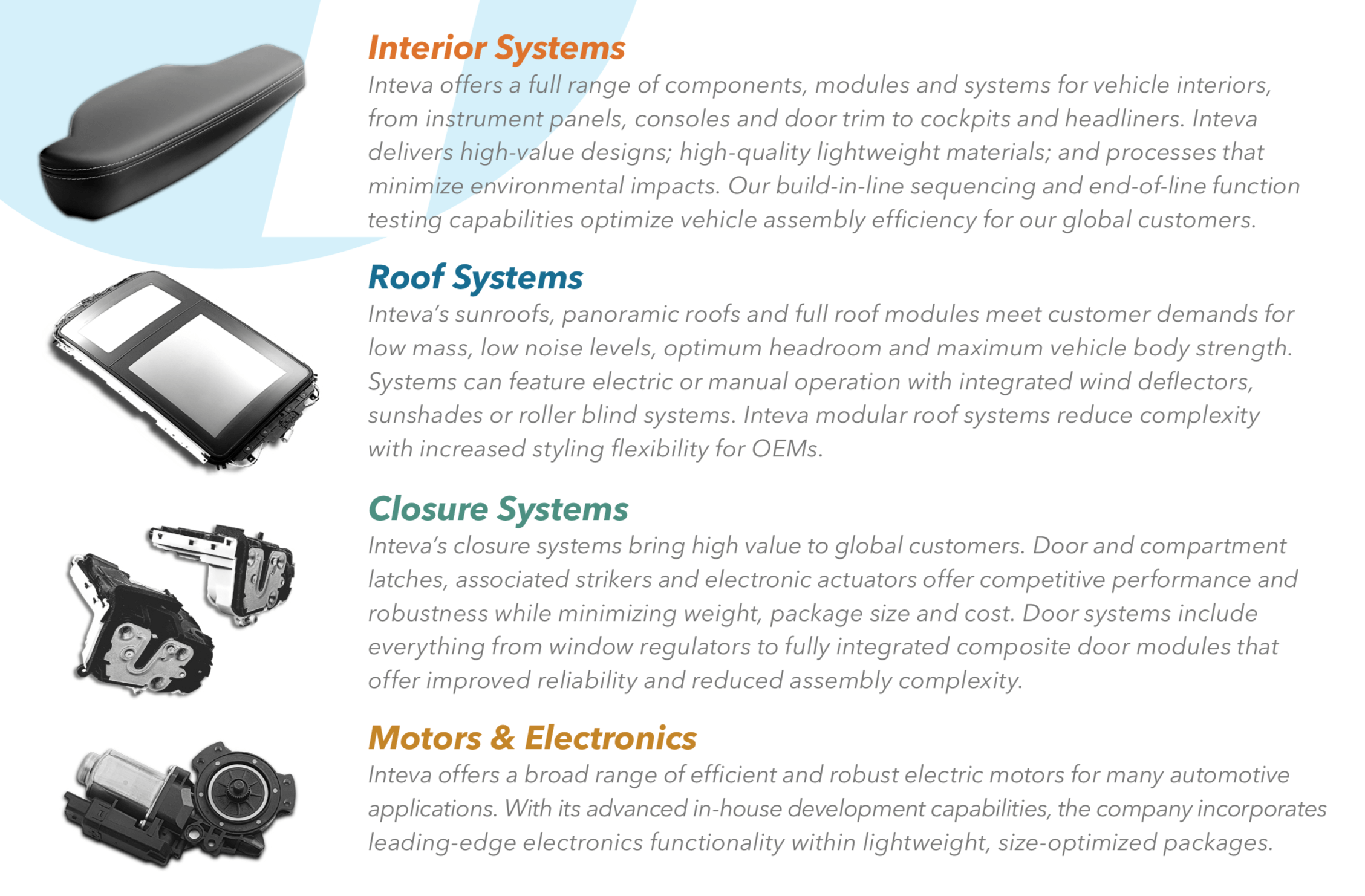

Host Plant: Inteva Products

Inteva Products Salonta Plant produces latches, window regulators and mechanical cables for several world class automakers. Salonta site has being in the lean journey for several years, achieving tangible benefits in performance, developing the teamwork to solve any kind of issue and continuously learning.

Committed to the highest standard for quality, Inteva meets all customer requirements and expectations. The company is focused on total commitment toward the continuous improvement of products and processes. Inteva employs over 15,000 team members in 18 countries. Inteva World Headquarters is in Troy, Michigan.

Inteva Products Salonta Plant produces latches, window regulators and mechanical cables for several world class automakers. Salonta site has being in the lean journey for several years, achieving tangible benefits in performance, developing the teamwork to solve any kind of issue and continuously learning.

Our product lines include Closure Systems, Interior Systems, Motors & Electronics and Roof Systems, and we have more than 90 customers, including virtually all of the world’s leading global and regional automakers.