Lean Expert Program

Train and support an internal team that will lead the development of people and improvement events.

This program aims to develop specialists with practical knowledge of the core Lean concepts and develop effective communication, facilitation, and training skills to support their teams.

Participants will be given the opportunity to develop their skills through hands-on exercises and projects defined after the training sessions.

Value Stream Mapping cases

A powerful method to analyze & Identify the main opportunities from a process.

Shop floor (Gemba) Activities

Learn the Lean methods with practical team activities conducted on the shop floor.

Improvement Planning and Management

Learn how to plan and coordinate the improvement efforts in an effective way.

Training length:

15 days

Who should participate:

Managers of operational and support departments, intermediate levels in production, quality and engineering, Lean practitioners.

Recommended industries:

Manufacturers: Automotive, Electrical / Electronic, Pharmaceutical, Food and Beverage, Printing, Plastics, among others.

- Exercises & real applications are focused on your own operations.

- Participants get a comprehensive understanding of the principles for Improvement.

- Develop a formal structure to facilitate improvement workshops (Kaizen events).

- Implement an action plan to improve the current situation and prepare the future improvements.

TRAINING AGENDA: BODY OF KNOWLEDGE

Kaizen Elements

- Muda Elimination

- Standardized Work

- Visual Management & 5S

- PDCA Approach

Shopfloor Management

- Tiered Accountability Meetings

- KPI and Visual boards for each level

- Leader Standard Work

KPIs and Smart Goals

Problem Solving Projects A3

- Tree Fault Analysis

- Ishikawa

- Brainstorming

Kaizen Project & Change Management

- Project Selection and Definition

- Managing Communication and Milestones.

- Stakeholder Management

Quality Improvement elements

- Andon, Poka Yoke, FMEA, Automatic Stops.

Elements of JIT & TPM

- One Piece Flow and Pull System

- TPM Management Model

- Autonomous Maintenance.

- SMED

Train the Trainer

Coaching & Project Review

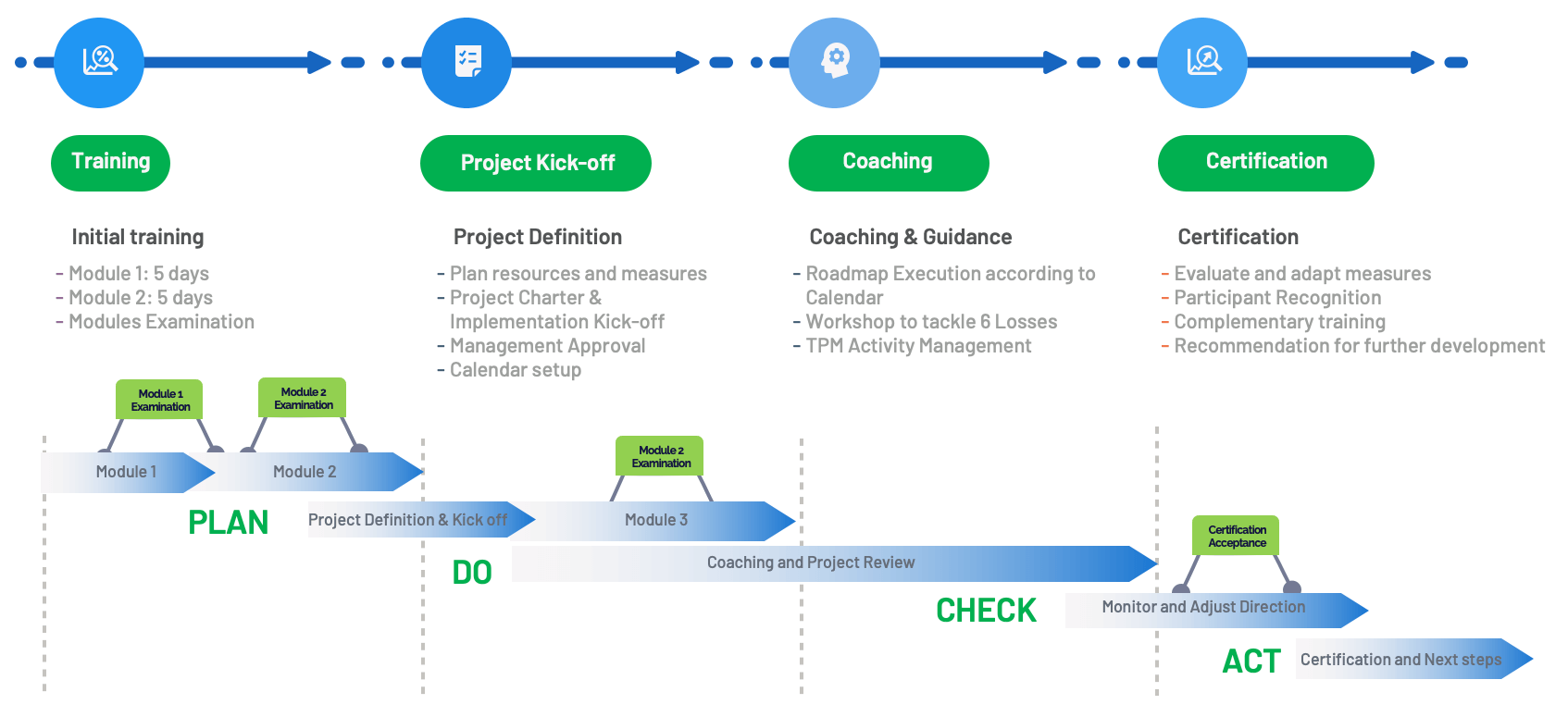

Lean Expert Program Overview

Reasons to work with us

Companies that work with us in Lean:

DO YOU WANT TO GO FURTHER? WE CAN ANSWER ANY QUESTION

Kaizen, Lean, VSM, Kaizen Romania, BUcuresti, Timisoara, Arad, Sibiu, Ploiesti, Pitesti, Brasov, Lean Manufacturing, Lean Thinking, PDCA, Problem Solving, Kaizen Gemba, Gemba, Value Stream, Lean Manager