Lean Management Principles

Our Lean Management Model

Our Lean Management model is based in the Toyota Way.

What is the Toyota Way? A philosophy of running a business based on developing and challenging people to continuously improve.

This approach aims to achieve a long term sustainable culture of continuous learning and improvement.

Why is a Long-Term Philosophy Foundation?

The focus from the very top of the company is to add value to customers and society. This drives a long-term approach to building a learning organization, one that can adapt to changes in the environment and survive as a productive organization. Without this foundation, none of the investments in continuous improvement and learning would be possible.

Lean Management Principles

The Lean thinking way is based on a series of principles.

-

Kaizen

-

5s

-

Kanban

-

Poka yoke

-

SMED (Single-minute Exchange of Die)

-

PDCA (Plan, Do, Check, Act)

-

Muda

-

VSM (Value Stream Mapping)

-

Visual Management

-

Standard Work

-

Andon

-

Just in Time

-

TPM (total Productive Maintenance)

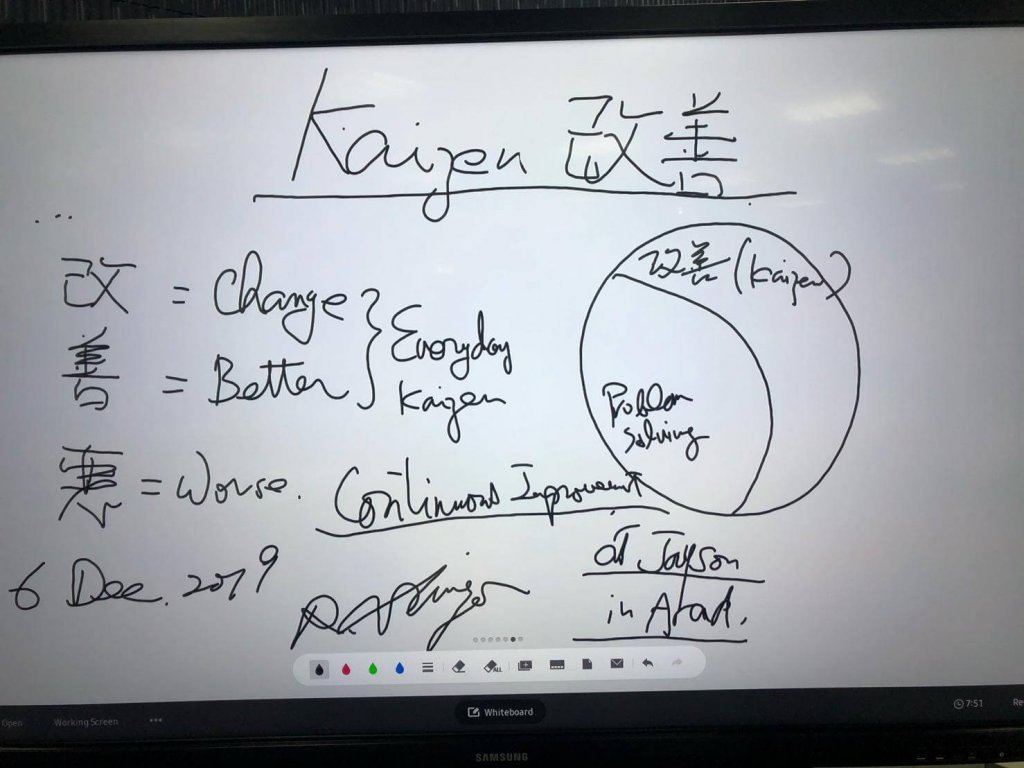

What is Kaizen?

Kaizen is a Japanese word that means Continuous Improvement. This Philosophy is used by many businesses impoving the way they work and standardizing work for the functional means of the operations throughout the whole company.

The kaizen way eliminates waste and sustains value added things.

What is 5s?

5s stands for the 5 Japanese principles: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). They mean sort, set in order, shine, standardize and sustain.

Using these 5 principles, the workplace is in concordance with the Just in Time Principle, helping employees work easier and practical.

What is Kanban?

Kanban is known as “Toyota nameplate system”. It is a scheduling system designed for Lean Manufacturing. Like 5s, it helps sustain the Just in Time concept.

This Lean Management Principle helps with the limitation of excess inventory at any point in production. It also limits the number of items waiting at supply points.

What is Poka Yoke?

Poka Yoke is also a Japanese term. It means mistake-proofing and it was established by Shigeo Shingo, the father of Ritsuo Shingo.

There are 2 types of Poka Yoke systems:

- 1. Not to occur (prevent) the mistake

- 2. Detect the failure when occured

What is SMED (Single-minute Exchange of Die)?

The SMED concept doesn’t mean to actually make the changeover in 1 minute, but in maximum ten, to increase flow and be more productive. The SMED concept doesn’t apply only in the manufacturing industrie, but in any industry.

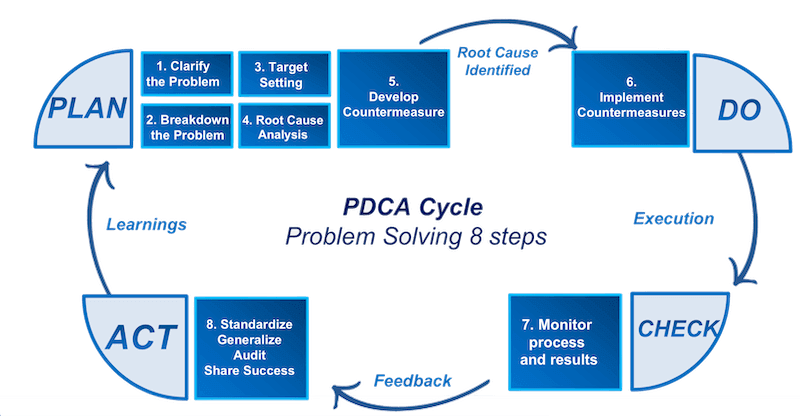

What is PDCA (Plan, Do, Check, Act)?

PDCA is the cycle used to correct the mistakes we made and prevent others from being made. First you have to plan an action, then you have to do it. After that you check (verify) the results to have a comeback for what went good and what went wrong, acting in the means of the results. If we know what our mistake was, we know not to repeat it

What is Muda?

Muda represents a Japanese term that defines wastefull actions. Eliminating Muda, we can increase the productivity more than we even think. Eliminating Muda can represent any type of waste. If it is waste, we can execute the process without it. Muda is the key in the Toyota Way Thinking.

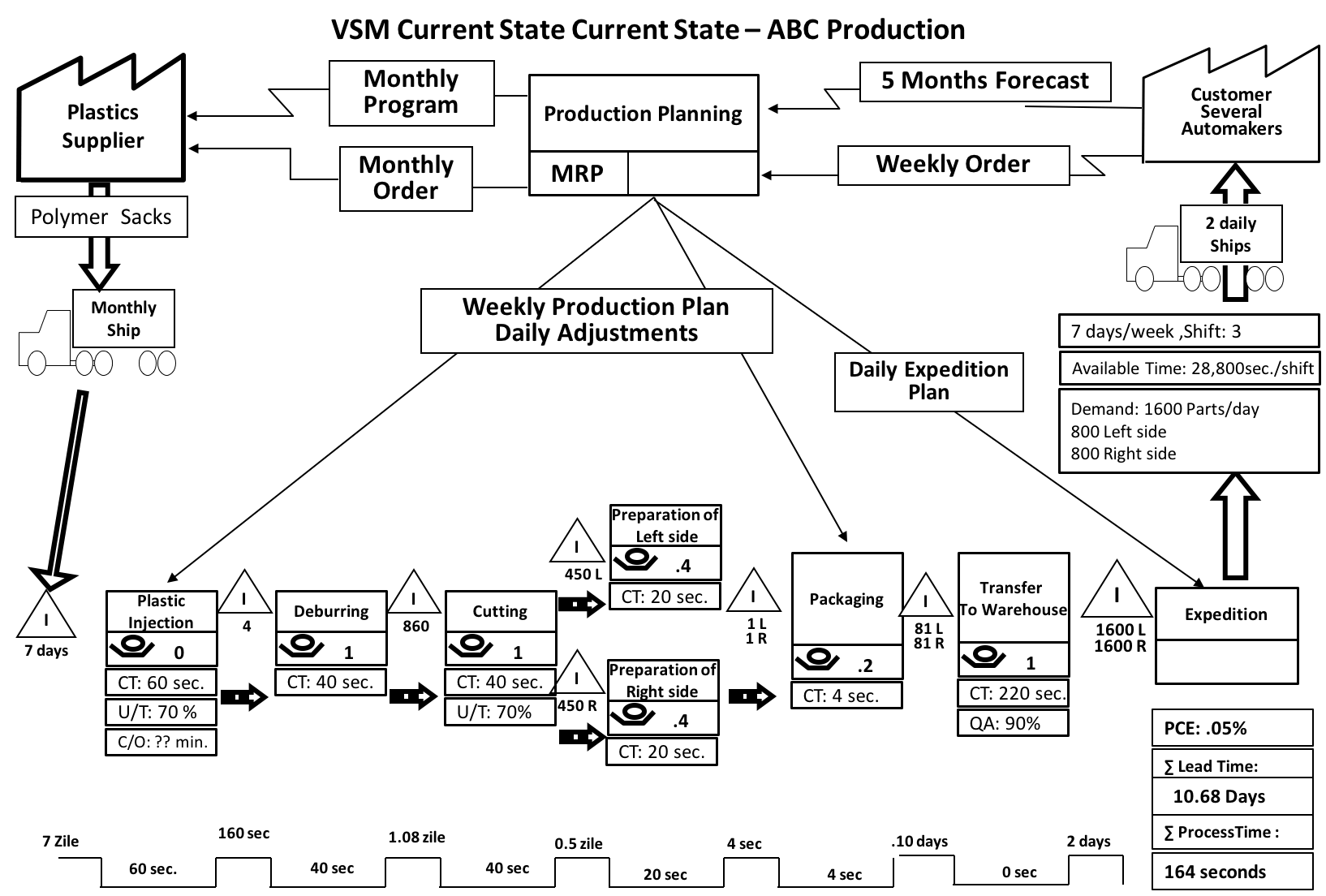

What is VSM (Value Stream Mapping)?

VSM represents a Lean Management way to enhance the information and material flow mapping. This tool helps follow the right steps in a process.

VSM structure

What is Visual Management?

Visual Management is the visual communication way to learn all about a process within a company without having to lose time asking about it. (waste) That means that anyone who passes through the shop floor should find out about the work state just by looking. This method doesn’t allow personal interpretation of the processes state.

What is Standard Work?

Standard work helps the work process. With the proper standard work documentation, any person can do the same job consistently with the help of the graphics and instructions. Therefore, Standard work is a Lean Management way to eliminate the waste and make the process easier to perform.

What is Andon?

Andon is a Japanese way to alert workers of a quality or process problem. The alert sistem is turned on by pressing a button and it can also have an incorporated system that stops the machine automatically. This Lean Management Principle helps eliminate the waste.

What is Just in Time?

The Just in Time principle originates in Japan and helps eliminate waste and fasten the process within the production system. It is helped by all the other Lean principles.

What is TPM (Total Productive Maintenance)?

TPM represents a system that maintains and improves the safety and quailty of production systems, through equipment, machines, employees and processes. The goal of this Lean Management Principle is to avoid breakdowns and delays of the production system.

TPM structure

CONTACT US

RECEIVE MORE DOCUMENTATION ABOUT OUR MODEL

Do you want to know more about it?

SCHEDULE A CALL WITH OUR CONSULTING TEAM