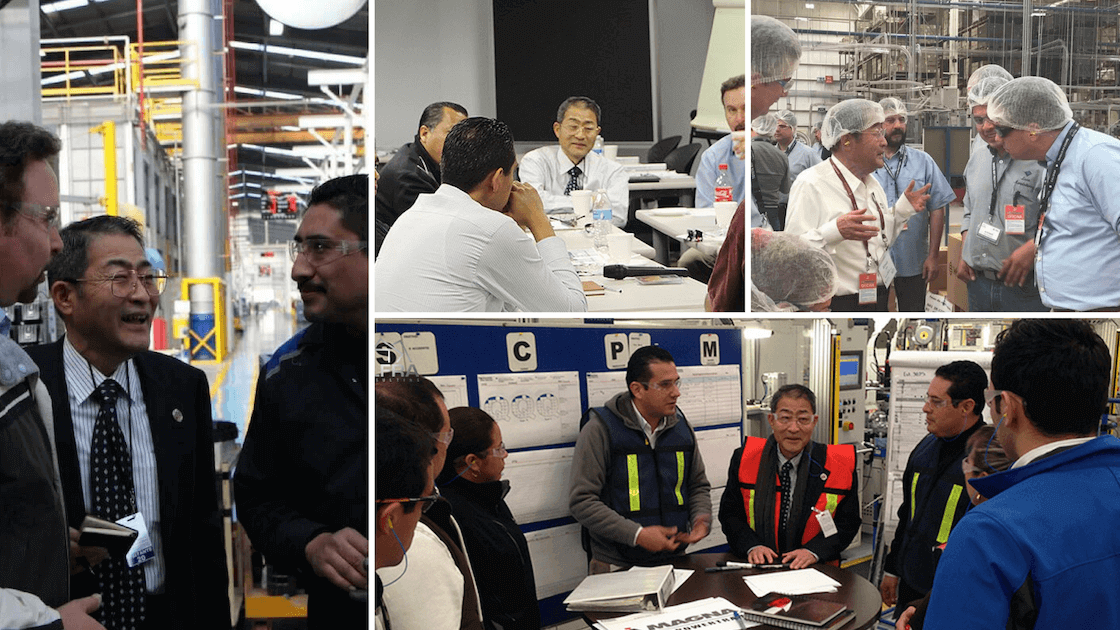

Ritsuo Shingo Gemba Practice

Experiences about leadership, culture and overcoming challenges.

23 November – Debrecen, Hungary

ONLY 10 EXTERNAL PARTICIPANTS

Ritsuo Shingo Gemba Practice

Hosted by:

Debrecen, Hungary

23 November 2018

Workshop Outline:

Ritsuo Shingo will share his perspective from all the experiences of his long life in the Automotive Industry, with over 40 years experience in the Toyota Management System, in different leadership roles.

Participants will have the opportunity to access first hand information about Leadership and the best practices for a successful culture development.

This is a management workshop not a Lean Tools training

Ritsuo Shingo will share his perspective from all the experiences of his long life in the Automotive Industry, with over 40 years experience in the Toyota Management System, in different leadership roles.

“Learn the Leadership and cultural experiences from a successful true Leader”

“Share experience and practice with other managers “

” Take the time to reflect and practice direct in the shop floor (Gemba)”

Ritsuo Shingo

Former President Toyota & Hino Motors China

- Ritsuo Shingo started his career with Toyota Motor Company in 1970 and retired in 2012.

- His father, Dr. Shigeo Shingo is a renowned expert in improving manufacturing processes, who helped to develop many aspects of the revolutionary manufacturing systems which comprise the Toyota Production System.

- He helped in the start up of five Toyota manufacturing plants outside Japan.

- Ritsuo Shingo spent more than 13 years in various roles at Toyota in Legal, Public relations and purchasing departments.

- He spent 5 years in the US, starting up Toyota Detroit Office as a purchasing agent and at Toyota Motor Kentucky.

- He worked also at Toyota Motor UK and then returned to the China Dept. in Japan.

- In 1998, had newly established the Toyota first Joint Venture in China, “Sichuan Toyota Motor” and became the first president of the Joint Venture.

- In 2007, had newly established the Joint Venture between Hino Motors and Guang-Qi Motors and became the first president of the Joint Venture.

Son of renowned Japanese guru Dr. Shigeo Shingo, in his +40 years in Toyota, He helped in the startup of five Toyota plants outside Japan. He set a record bringing a Toyota manufacturing plant to profit in its first year of operations.

Participant’s Feedback

-

I can say that it was the first time I participated in a real Lean manufacturing workshop. I absolutely loved to be part of Ritsuo Shingo training, this opportunity strengthen my confidence and motivated me even more to give our best in facing the new challenges. Ritsuo Shingo is definitely an outstanding leader.

Plant Manager Inteva Products -

It was a very good experience, I had the opportunity to share with people coming from different plants/industries and to learn from the very long experience of Ritsuo Shingo. Listening to Ritsuo Shingo during the workshop I realized that for my plant is very important to create a company culture, a culture of continuous improvement which will sustain the lean tools.

Plant Manager BOA Romania

Host Plant:

FlexiForce, established in 1980, is specialized in the design, procurement, production and distribution of hardware parts, automation, panels and hardware systems for residential and industrial overhead doors.

Worldwide, FlexiForce believes strongly in the market opportunities of independent, often local or regional, door producers (OEMs).

FlexiForce products and services support door companies in offering competitive door solutions to their markets. FlexiForce core competences lie in the design and quality of the products and systems, but even more in understanding the market need for an efficient supply chain.

This is facilitated through worldwide FlexiForce production and warehouse facilities in Canada, United States of America, United Kingdom, the Netherlands, Spain, Hungary, Turkey, Italy, Poland and China.

FlexiForce is specialized in the design, procurement, production and distribution of hardware parts, automation, panels and hardware systems for residential and industrial overhead doors.

FlexiForce core competences lie in the design and quality of the products and systems, but even more in understanding the market need for an efficient supply chain.

Participant’s Feedback

-

I can say that it was the first time I participated in a real Lean manufacturing workshop. I absolutely loved to be part of Ritsuo Shingo training, this opportunity strengthen my confidence and motivated me even more to give our best in facing the new challenges. Ritsuo Shingo is definitely an outstanding leader.

Plant Manager Inteva Products -

It was a very good experience, I had the opportunity to share with people coming from different plants/industries and to learn from the very long experience of Ritsuo Shingo. Listening to Ritsuo Shingo during the workshop I realized that for my plant is very important to create a company culture, a culture of continuous improvement which will sustain the lean tools.

Plant Manager BOA Romania

Training Details:

Aimed to: Senior Leadership and Managers from all kind of manufacturing companies

Training Length & Language: 1 day – English

Participation Fee:

950 Euro/participant >> 870 Euro/participant before 15 May

Participant receives:

Training Material & Recognition

Lunch & Coffee break during the 3 days

Limited to 10 external participants

Receive the brochure with all details

contact@alfraconsulting.eu

Romania Office: (+40) 364228080

or write us here:

Workshop Agenda

Ritsuo Shingo Presentation (8:00 – 8:30)

Concept of 4S – Gemba Activity (8:30-10:30)

Waste (Muda) Identification – Gemba Activity (10:30-12:50)

Lunch: 13:00-13:30

Problem Solving & finding – Gemba Activity (13:00-15:20)

Standardization – Gemba Activity (15:20-17:40)

Total Participation – Gemba Exercise (8:00-10:30)

Autonomation / Build in Quality – Gemba Exercise (10:30-13:00)

Lunch: 13:00-13:30

QC Circle – Gemba Exercise (13:30-16:25)

Quality Control (16:25-17:00)

Motivation of Workers– Gemba Exercise (8:00-8:30)

Visual Control – Gemba Exercise (8:30-11:00)

Leader & Leadership – Gemba Exercise (11:00-12:00)

Robbery Story – (Elevator Story) (12:00-12:10)

Never Give up – Be Challenging (12:10-12:30)

Self Evaluation (12:30 – 13:00)

Lunch: 13:00-13:30

Culture (13:30-14:00)

Gembaism (Go & watch) – Gemba Exercise (14:00-16:40)

Brain Storming – Gemba Exercise (8:00-10:40)

Category Principle (10:40-11:10)

Level Production ( Heijunka) – Gemba Exercise (11:10-12:30)

SMED System – Gemba Exercise (12:30-13:00)

Lunch: 13:00-13:30

Pull System/Push System – Gemba Exercise (13:30-15:00)

Lot Production & One Piece Flow – Gemba Exercise (15:00-16:30)

Blame responsibility/Detect cause (15:30-14:00)

Certificate/Group photo – (16:00-17:00)