Value Stream Management

In-field Training for leadership teams

Manage your operations in order to improve the flow of value to your customers.

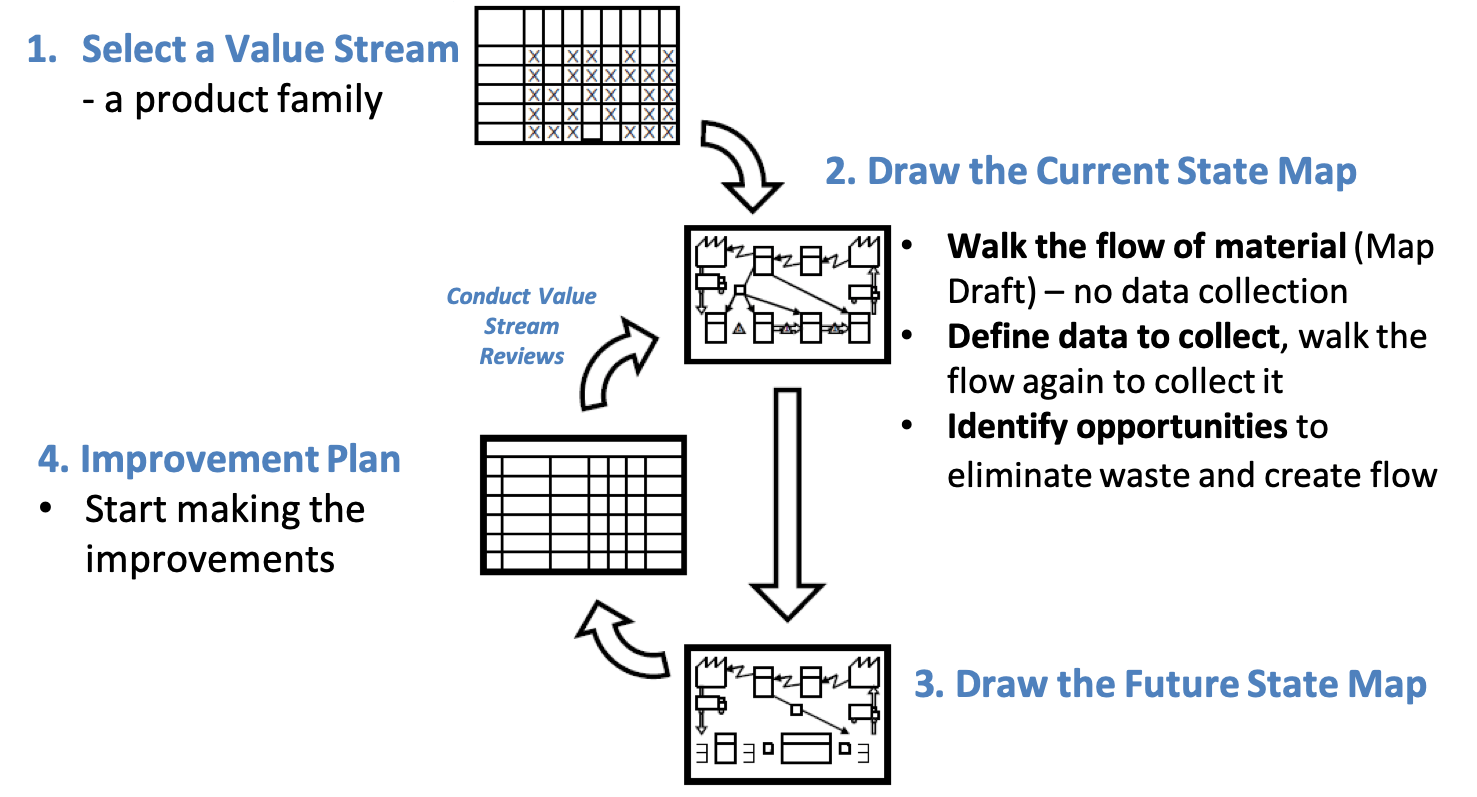

In this workshop we will explain the importance of building a work structure to streamline the flow of value to your customers and assure their satisfaction.

We will explain the concept and practical implementation of Value Stream Design, in order to plan and implement improvement activities.

We will also analyze the material and information flow from the host plant, in order to identify the main opportunities and develop a value stream design (Lean value stream plan).

Identify main opportunities and design a lean value stream

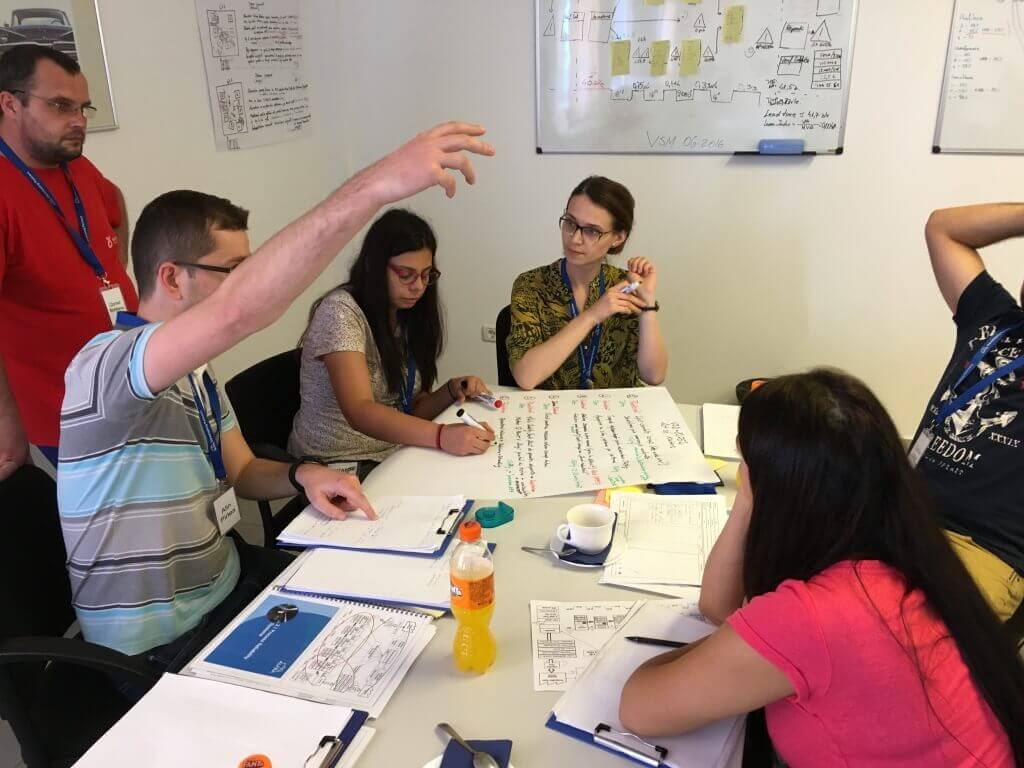

Participants will split into teams to perform activities in the shop floor and present their observations

Practical Learning

Learn the concepts from examples, group exercises and trainers’ experience

Group Discussion

Share experiences with managers from different industries and background

Shop Floor Exercises

The training is hosted by a factory, with activities direct in the process area

Location: Arad, Romania

Language: English

Who should attend?

Leaders who wants to understand how to use visualization of the materials and information flow to set company objectives and deploy it in the different areas of the organization

This session aims to:

-

Show the difference between a functional (traditional) organization and a value stream organization.

-

Present the main benefits of building a work structure to streamline the flow of value to your customers and assure their satisfaction.

-

We will cover the concepts with shop floor exercises and real implementation examples.

Instructed by seasoned Lean Coaches

Laszlo Seres

Former EMEA Lean Manager & Coach

László has deep experience in automotive industry in different countries (Germany, Hungary, Romania..) from middle level to EMEA management position . He was responsible for supporting and establishing different functions like Industrial Engineering, Maintenance and Operational Excellence, with focus on developing the people and teams in these areas.

László has 10 years of experience working in several countries like Hungary, Germany, Spain, Romania, Macedonia and Ukraine working for companies like BOSCH, TAKATA or Joyson Safety Systems

He coached people in the entire organization to ensure proactive continues improvement and problem solving attitude.

He is the Co-founder of Lean Process Development Engineer program at University of Miskolc.

Main expertise:

- People development with Coaching & Improvement Kata method

- Problem Solving development programs & Coaching

- Supporting the implementation of TPM system

- Production system planning, Industrial engineering, Material & Information Flow management

Edgar Cardenas

Lean Advisor & Coach – Europe Operations Director

Edgar has work the last years in countries like Romania, Hungary, Russia, Mexico, Colombia, Spain and USA…, providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes, in several industries including: Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, among others.

He recently provide support to companies like Bosch, Hino Motors, Mercedes Benz, Kimball, Zebra technologies, Takata, Inteva Products, Dawn Foods, BOA, Mars, Rubbermaid, Faist Group, Emerson, Exide, Harsha Engineers, Steelcase..

-

Lean for Business Processes corporate trainer for several companies

-

Operational Excellence speaker at several international Lean Conferences & Summits.

-

He has developed in Lean Management over 1000 managers & leaders

-

Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta , Georgia.

-

Edgar has received direct coaching and professional development from renowned leaders like:, Ritsuo Shingo (Former Toyota President ), PhD. Jeffrey Liker (The Toyota Way), Gary Convis (Former VP at Toyota N.A. )

Host Plant:

The BOA Group is one of the world’s leading manufacturers for flexible mechanical elements for the automotive and aerospace industry as well as for a wide range of industrial applications.

The headquarters is based in Stutensee, Germany. Today, the BOA Group consists of 15 subsidiaries and shareholdings in 13 countries.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

BOA Romania is located in Arad. The plant started its operations in July 2014 producing metal hoses and exhaust gas recirculation pipes for the automotive industry as well as V-clamps for industrial applications.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

In the industrial division, the BOA Group delivers flexible elements for applications in the Energy sector, Shipbuilding, Rail and Heavy Engine industry. Customized expansion joints are designed for Petrochemical, Chemical as well as Oil & Gas Pipelines.

Precision metal bellows and ultra clean metal hoses complete the product range and offer high tech product applications in the Vacuum, Semiconductor & Magnet Technology market.

Zona Industriala Nord-Vest, str. IV, Nr. 13, Arad, Romania.

Training Agenda:

- Confirm True North – Cascade

- Group Exercise: Everyone on the same page for True North

- Why – Mission , Purpose

- How – Values and Operating System

- What – Vision and True North Goals

- Philosophy and Beliefs

- Roles and Responsibilities for each Level

- Servant Leadership in action

- Job Security Philosophy

- Roles and Responsibilities for each Level

- ID “Current State” of Lean Culture and ID Gaps in relation to

- foundations of DMDS:

- 5-S, Standardization, Training Method, Visualization

- Value Stream Organization and Management Structure

- Exercise – each team report out “Current Situation” of their Lean Work Systems

- Gemba Exercise to ID “Current State” of Lean Culture and ID Gaps in relation to foundations of DMDS (5-S, Standardization, Training Method, Visualization, Value Stream Organization & PDCA). Large group will break into sub groups for each corresponding KPI Pillar

- Check Action – each team report out “Current Situation

-

- Key Performance Indicators

- Enterprise – Business and Financial

- Vertical Cascade – Tiered approach “Pillar” KPI’s

- Horizontal – Functional Support Indicators

- Main, Sub and Process KPI’s

- Key Performance Indicators

-

- Group Exercise: Recommend KPI Structure for all three levels of the organization. Include all pillars of Safety, Quality, Service/Delivery, Cost and People (other)

- Recommend Enterprise Wide KPI (and/or Main KPI)

- Recommend Vertical Cascade KPI’s – Main – Sub and Process

- Executive

- Manager

- Value Added Level

- Group Exercise: Recommend KPI Structure for all three levels of the organization. Include all pillars of Safety, Quality, Service/Delivery, Cost and People (other)

-

- Systematic Problem Solving at all level

- Executive to Value Added Member

- Boulders, Rocks and Pebbles

- Lean Leader Standardized Work

- Systematic Problem Solving at all level

-

-

- Group Exercise – Develop Role and Responsibility and “Leader Standardized Work” for each Level of Leadership

-

-

-

- Daily Huddle Standardized Work Enterprise – Business and Financial

-

-

- Idea Implementation and Escalation & Problem Solving Teams

- Strategic, System and Daily (Boulder, Rock and Pebble)

- Check status of these three levels “at the gemba” for all levels and all pillars

- Group Report Out – Three Level Problem Solving

-

- Group Exercise – Develop Role and Responsibility and “Leader Standardized Work” for each Level of Leadership

- Daily Huddle Standardized Work

Wrap up, debrief and next steps action plan