What is 5S?

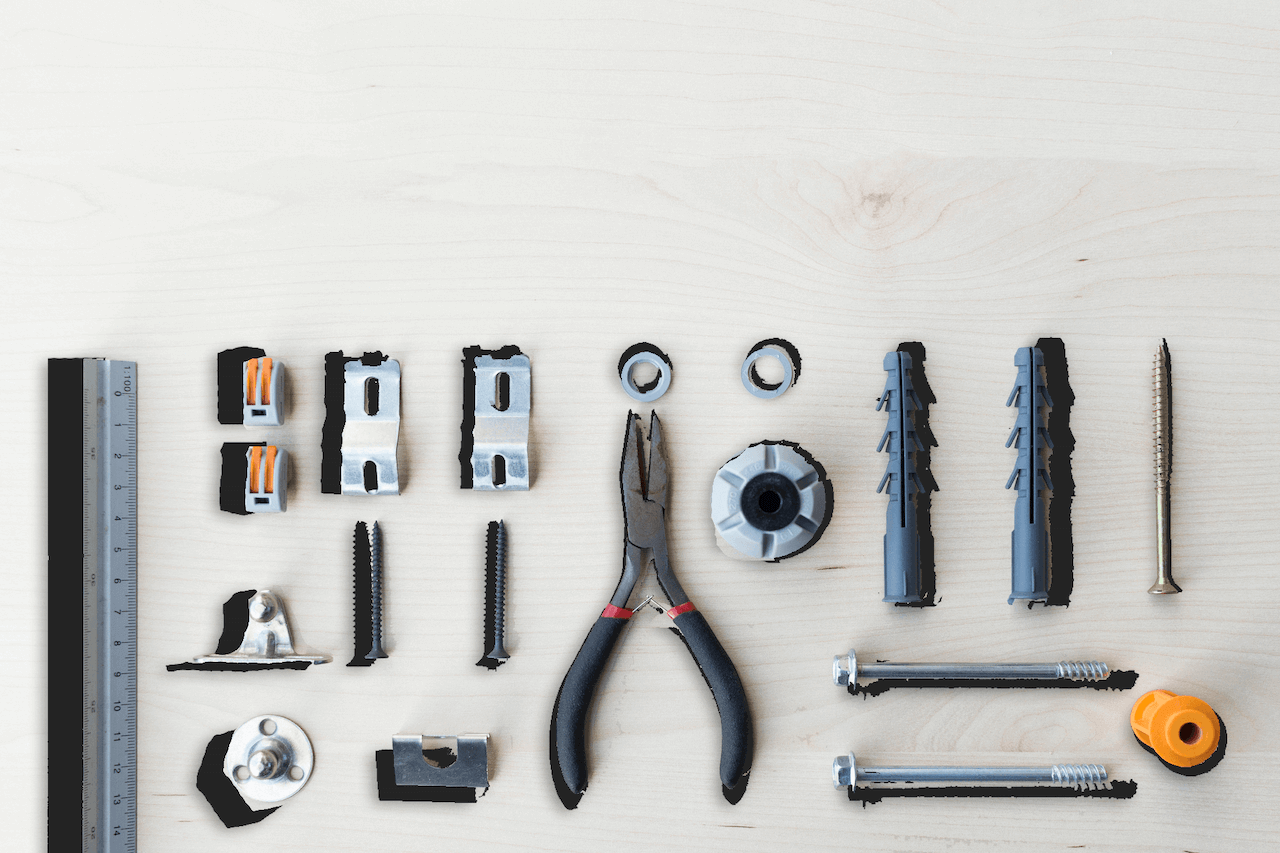

5S means having an organized workplace, to identify sources of waste.

It is one of the first steps to develop stability in a process, and move to abnormality management.

5S is a Japanese concept which is practiced as well in normal life. its main scope is to guide/reinforce the desired behavior and spot abnormalities.

Lean management starts with 5S, workplaces without it cannot produce with quality.

Most of the time, workplaces with low morale are disorderly and lack discipline.

The thorough implementation of 5S is the first step in making a good workplace. See below for the definition of each one of 5S:

- Seiri: Sort

- Seiton: Set in order

- Seiso: Cleaning

- Seiketsu: Neatness

- Shitsuke: Discipline

5S Policy

Sustain a safe, clean & organized workplace where deviations are easy to identify

Sort (Seiri)

Distinguish between what things are needed and what are not, and get rid of the unnecessary ones and of the things that should not be seen in a workplace. (Raw Materials, WIP, Tools, Machinery)

-

Distinguish necessary things from useless things and get rid of the useless objects

-

The main point is to establish rules regarding elimination and how much you can throw away.

Search for the 3 key points: utility, frequency of use and cost.

Set in Order (Seiton)

Put necessary things in order so that they are easy to use. How fast and how easy si it for you to pick up necessary objects?

Identify the location for object placement:

-

You can’t put things in the zone that’s not implemented for them.

-

The act of putting objects in a place temporary should be eliminated.

Key points to search for : Economy of movement (Muda)

Shine (Seiso)

Make sure that everything is clean and well-maintained, including the machines, dies, jigs, tools, measuring instruments. Also make sure that the workers are clean and tidy—your hair, hands, working clothes, and shoes—make it the usual.

The process of cleaning acts as a form of control that lays out abnormal conditions and pre-fail that can affect quality or the machine’s functionality.

-

Creating systems that keeps the work area clean.

-

Work clothes should be clean.

-

Don’t wear anything that can deteriorate the products.

-

Get enough light. (Darkness hides problems)

Neatness (Seiketsu)

Maintain high levels of seiri, seiton, and seiso.

Assure that procedures and settings are uniform throughout the whole operation’s itinerary to promote interchangeable character.

-

Develop a system to easily detect deviations and make visual expectations.

-

Setting standards in the organization’s workplace, anyone from the company can visually inspect any zone of the organization at any time.

-

Develop everyday standard practices.

Sustain (Shitsuake)

Train everybody so that they abide by the rules and regulations. Make it a practice through mutual admonition.

Sustaining a stable work environment is a continuous process of continuous improvement.

Key points:

-

Ensuring good conditions for every employee to help them practice what they have learned.

-

Creating a Dashboard for every zone to point out the elementary progress.

-

Implication of people from all company levels.

-

The final responsibility of the 5S Concept implementation is senior management’s.

-

Every day explanation of why 5S basics should be improved.

Conclusion on 5S

1) If you put things away without sorting them, it is mere storage rather than seiri, look back at your standards to define what you really need to complete the job done in the workplace, and also challenge to always reduce the number of things needed.

2) In seiton, you always need to consider efficiency—are they easy to fetch and use? The objective is not to make things look good; but make sure the necessary things can be reached fast and effortlessly.

3) Seiso is about finding ways to keep clean, focus on the sources of contamination, clean, and keep clean every day at every time.

Try not to act superficially. Before implementing the 5S, you need to understand why they should be done, if any of your efforts will not lead to identifying abnormalities and sources of waste, better don’t do it.

How can we implement 5S? and Which are the benefits of implementing 5S?

CONTACT US

RECEIVE MORE DOCUMENTATION ABOUT OUR MODEL

Do you want to know more about it?

SCHEDULE A CALL WITH OUR CONSULTING TEAM