1.What does lean mean?

The meaning of lean represents „do more with less”, „healthy”,” agile”, „adaptable”, „continuously improve”.

The lean management approach is to increase the value ratio through improving the working conditions (safe, easy, simple) for those adding value.

2.What is the starting point of lean implementation?

The critical point in any lean implementation is a clear direction and full engagement from the company’s leadership. If these basic conditions are not present then the company might only have some pockets of lean tool deployment but won’t be able to develop a lean culture, where the lean DNA is in the behaviors of everybody inside the organization.

3.What are the benefits of lean implementation?

By embracing the lean philosophy, organizations will improve process efficiency by reducing waste.

A right lean approach boosts both, productivity and employee satisfaction, increases profits and generates more productivity with less waste and better quality. Finally, all of these results create a more profitable company.

And probably the most important benefit is creating an organization capable to learn and adapt continuously to overcome any kind of future challenges, assuring not only survival but success in the long term.

4.How can we maximise the impact of lean deployment?

You can’t have an effective lean tool or lean toolkit implemented in your company without developing a lean organization at the same time.

It’s like making a puzzle without a master picture and, using very few pieces on the table. As a result, you could only guess the whole image… So, by developing only a limited number of lean tools, and due to interconnection between them, it is impossible to achieve real performance. And the sustainability of those lean tools is just for a short period of time.

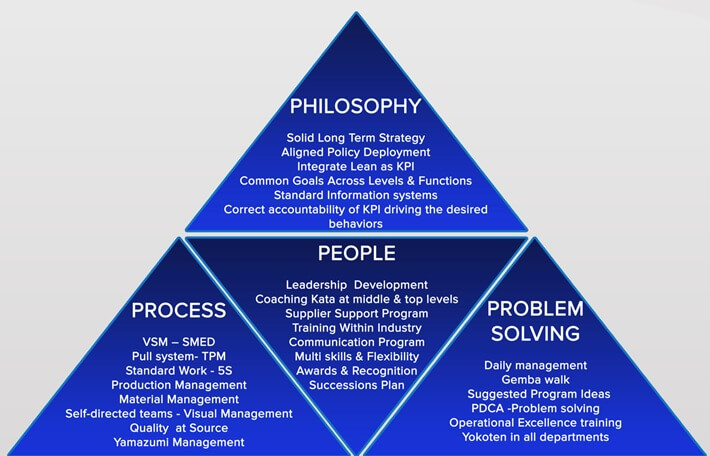

The best way to grow and sustain a lean organization is to use a systemic approach, where systems and tools are interconnected to consistently drive the right behaviors that will generate the right results.

An example of this are our Lean Transformation Model or the Shingo Model

5.How to identify a lean company?

A lean company can be recognized through some core characteristics of (routines and behaviours) that at the end express its organizational culture.

-

Aligned: the vision of the company’s CEO, plus key business objectives and projects, are logically reflected and linked to the goals of leadership and employees.

-

Focused: organization is concentrated on customer value having a clear understanding of its internal and external customers’ expectations.

-

Collaborative and: there is open & 2-way communication on vertical, between the top and bottom of the organizational pyramid, but also horizontally between different compartments. They are open and volunteer to be involved in transversal problem-solving.

-

Tenacious: when a failure occurs this is not a reason for blaming but a source of a lesson learned and an incentive to act with even more energy.

-

Engaged: the major motivation is triggered by the pride of employees to be part of an organization that promotes the real value: of the product/ service delivered and of its members.

-

Humble: the success is celebrated but is just the baseline for a future improvement.

-

Methodological: all processes have clear ownership, they are well defined and people known who does, what, when. There is a process for evaluation of the organizational system, in charge to measure the current status and identify new opportunities.

-

Proactive: by identifying the risks and taking action as soon as possible to prevent issues.

6.What are the 5 lean management principles?

There are five key lean principles acc. to Womack and Jones:

- identify the value,

- mapping the value stream,

- create flow,

- implement a pull system, and

- search for perfection through continuous improvement.

So, if you develop only a limited number of lean tools, and due to interconnection between all of them, it will be impossible to achieve expected goals.

7.What are the 7 wastes?

The 7 types of wastes and non-value added, that are under the „magnifying glass” of lean to be reduced are:

- Defects;

- Overprocessing;

- Transportation;

- Inventory;

- Overproduction

- The motion of people, equipment, or pieces;

- Waiting time.

More lean practitioners use to add the eighth:

- Not utilized talent.

To deal with the last one, but not the least, we recommend focusing on Organizational deployment, which is a critical and science-based process that helps an organization build the capacity to change and achieve greater effectiveness.

8.What are the lean systems and tools?

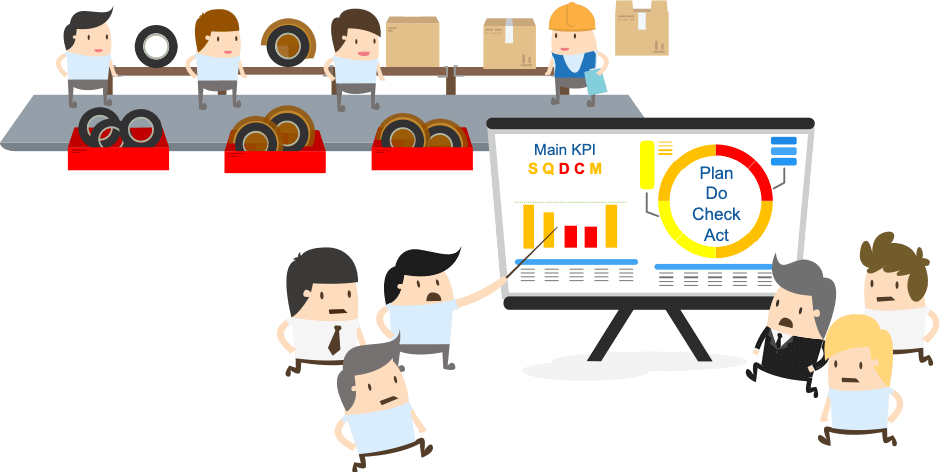

The Lean Systems are composed by several tools, with the scope of visualize abnormalities to improve working conditions.

Some examples of the main lean tools:

- Just-in-Time (JIT): One Piece Flow, Kanban,

- Value Stream Mapping (VSM)

- Total Productive Maintenance: Autonomous Maintenace

- Quality at the Source: Error Proofing or Poka-Yoke, Andon, Jidoka.

- 5S

- Standard Work and Visual Management

Each of them should be well explained and understood before implementation because a wrong deployment and later, poor sustainability are the common mistakes we can see.

In order to avoid these issues, lean expert involvement and support can make the difference between failure and success.

You can learn a bit more about the lean principles and practices here:

9.Where lean can be applied?

Once the essence of the lean principles is understood, the implementation of its tools may be different from one industry to another, but its main purpose will remain valid. The purpose of increasing value while improving working conditions applies to a large spectrum of different activities and processes like manufacturing, services, telecommunication, IT, medical, product design, banking, education, etc.

10.What is „the secret” of a successful implementation?

Effective implementation of the lean concept is not focused on tools but on people using tools, to improve their lives and performance.