5S Training & Deployment

5S is a popular Lean concept but few organizations understand it and apply it properly, its main objective is to set the foundation for continuous learning & improvement of the work conditions.

Expected Outcomes:

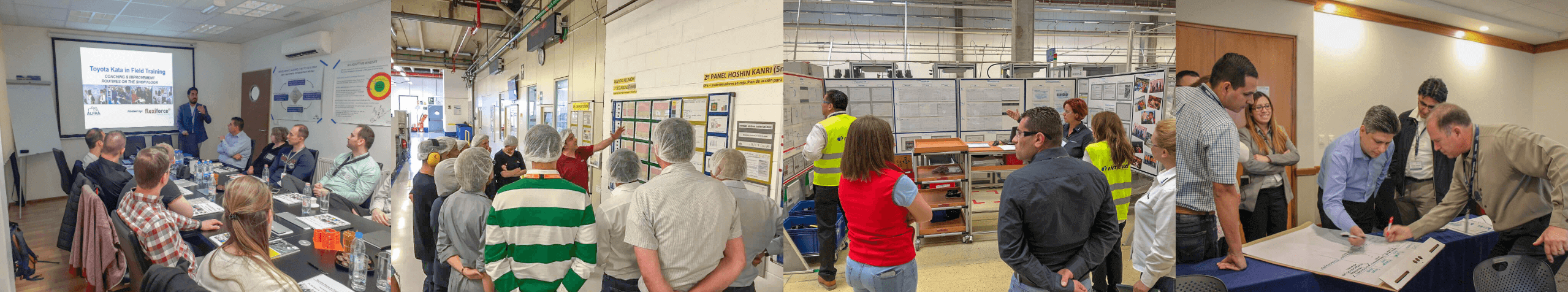

Applications on Shop Floor

We will perform activities directly in the process area.

Real Case Examples

We will review examples of implementations from other companies

Team Work + Guidelines for your own Implementation

We will have teamwork exercises and plan for your own implementation

Together with the company team, we will define a deployment plan to take the first steps to build problem awareness and a continuous improvement mindset, then we will train and support the team in the pilot implementation.

Training Length: 3 days

Aimed to: Team Leaders, General Managers, Managers & Leaders in Maintenance, Manufacturing, Engineering and Continuous improvement.

Approach: Together with the company team we will define a deployment plan to take the first steps to build problem awareness and continuous improvement mindset, then we will train and support the team in the pilot implementation.

- Train team leaders & members from operational and support areas

- Train 5S champions (management) to provide feedback

- Define 5S accountability by area

- Define Pilot and objectives

- Define a 5s Routine, evaluation, and tracking board

- Execute the action plan & follow up.

- Improve your actual way to organize the workplace and visualize the performance to manage operations in a better way.

- Establish standard routines at all levels of the organization.

- Gain knowledge through the real implementation that will provide the basis for developing your own workplace.

Instructed by seasoned Lean Coaches

Do you want to go further? we can answer any question

5s training, 5s, 5s implementation, 5s deployment, IE, process optimization, process improvement, time measurement, ergonomics training, ergocheck, Layout optimization, Layout design, MTM, motion analysis