What is Built-in Quality?

Built-in quality means developing a product or service right from the first time

Quality is the result of a process, so in order to assure quality, we need to control and improve from its source.

Quality is the best strategy for growing our company and to be able to create the work culture we are looking for.

Quality Control

Focus in Observing the Product

- End of Line Inspection

- Successive Inspections

- Sensors & Cameras for presence

Approach:

Defect Detection & Feedback

Main Objective:

Don’t let pass defects to the customer

Source Control

Focus in Observing the Process

- Error Proofing devices: Fixtures & Gages

- 5S and Visual Management

- Source Inspections

- Standard Work Adherence & LPA

Approach:

Error Detection & Feedback

Main Objective:

Don’t let defects to happen

Source Control: Quality is generated from the 4Ms

Materials: Factors related to the material or the components utilized in the manufacturing process in the detected part.

Method: Factors related to the process and the way how the product is manufactured, processed and delivered.

Manpower: Factors related to the ability of the people doing and executing the job defined. Training and communication for instance.

Machinery: Factors related to the machine ability, repeatability, software, error proofing, electronic controls.

How does a Built-in Quality System look like?

1. Define clear standards

Define the desired conditions or pattern for each of the 4M, this are the parameters/standards that if respected will deliver first time quality.

2. Make abnormality visually apparent.

Find ways to spot any deviations effortless and inmedialty, visual, sensors, cameras, and devices that detect abnormalities are helpful.

3. Quick Response to Abnormalities

It is useless to have quick ways to identify abnormalities, if any action is taken, quick response (normally from the team leader) should arrive to isolate the problem and bring process to normal conditions as soon as possible.

4. Countermeasure – prevent building or passing the defect

Problem solving activities must be done in order to identify the root cause of the abnormality in order to prevent reoccurrence.

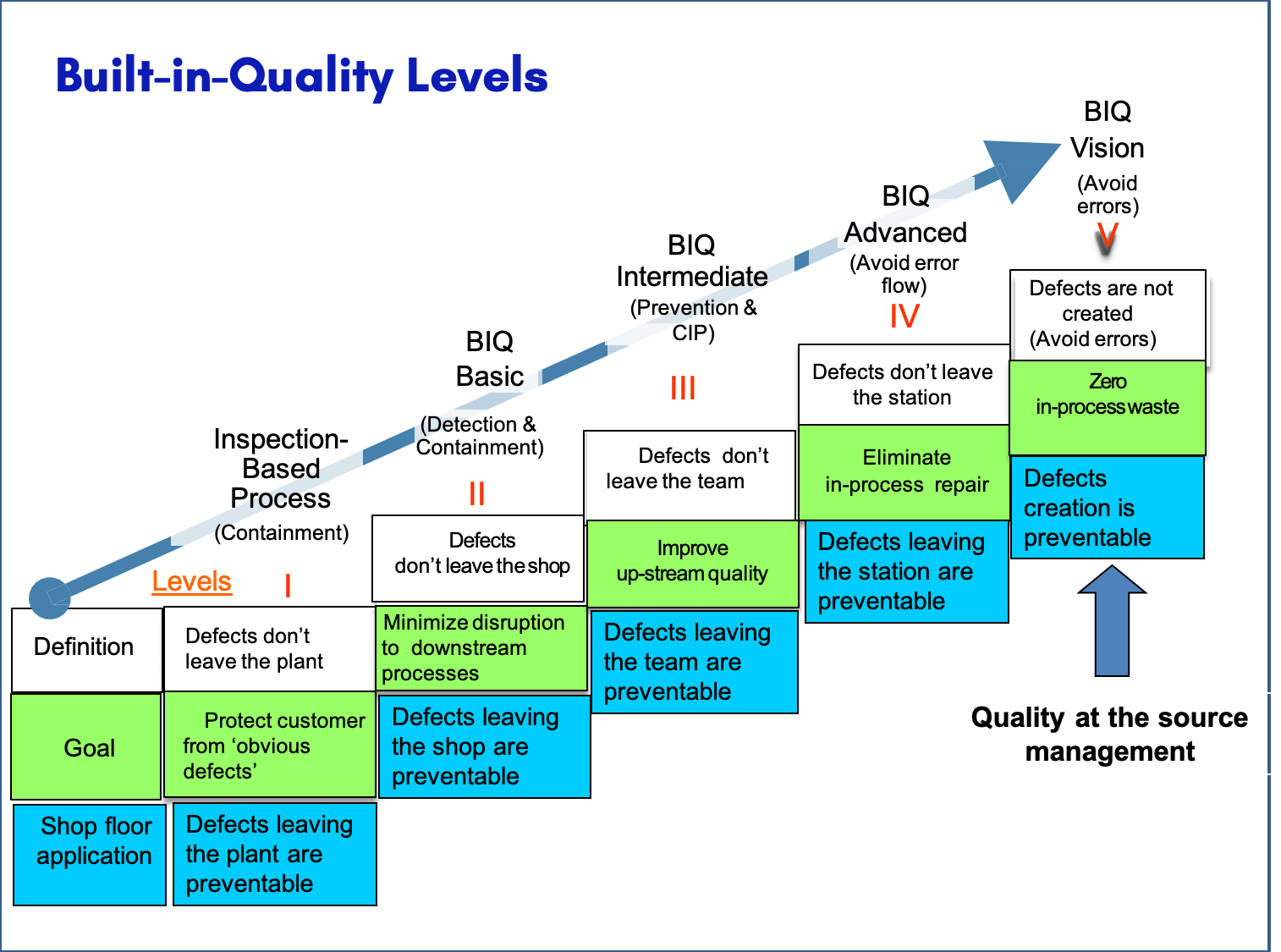

Built-in Quality Levels