Built-in Quality Training

Open Training

Definiți fundamentul unei culturi de zero defecte prin asigurarea calității de la sursă.

Calitatea este cea mai bună strategie pentru dezvoltarea companiei noastre și pentru a putea crea cultura de lucru pe care o căutăm

Nivelul de calitate pe care îl căutați poate fi atins prin executarea riguroasă a procedurilor standard și îmbunătățirea acestora.

Nivelul de calitate pe care îl căutați poate fi atins prin executarea riguroasă a procedurilor standard și îmbunătățirea acestora.

În acest workshop ne vom concentra pe cum să profităm mai mult de sistemul nostru real de calitate, îmbunătățind modul în care îl folosim și îl gestionăm zilnic.

Training Team

Dan Dogojie

Lean Management Senior Consultant

Dan is a senior-level advisor with +25 years of experience in an industrial environment (automotive, electronics). He has extensive experience as plant manager for Electrolux, Autoliv, Panduit, and Delphi, responsible for operational and financial deliveries of plants.

He has experience in production plant start-ups, green-field / high–growth plant operations, crisis stabilization, task-forces operational, and general plant management.

- He was also production Director at Group Dacia-Renault Mioveni plant, responsible for car manufacturing departments operations: stamping, welding, paint shop, and car assembly. He led the production System and LEAN responsible for the EMEA region in the Autoliv airbag division, as ACE Program Manager;

- He starts applying lean manufacturing principles in the Solectron plant. More experience followed in Dacia-Renault OEM plant, by obtaining Renault Production System- black belt title as Industrial Organizer and applying RPS strategies in Mioveni plant.

- He held positions of Materials Control and Logistics Manager for Philips and BOS Automotive, with activity start-up and formation of Supply Chain & Logistics Department of BOS Automotive (green-field) for custom clearance, transportation coordination, shipping-invoicing, raw material-finished goods warehouses, material pull-systems among plant value-streams, indirect goods purchasing, production-demand-dispatch planning, material control buyers teams; start-up of 2 consolidation warehouses for raw material supply chain (located in Germany) and 2 JIT warehouses/ OEMs located in Austria and Spain.

Nicolae Gligor

Lean Management Senior Consultant

Nicolae has over 25 years of successful experience in different industries: Automotive, Chemicals, Automation & Electronics, and Aerospace. He led Problem Solving projects on complex business issues across multiple sites in Europe, North America, Australia, and Asia.

He had roles such as Senior Quality Manager, Global Quality Improvement Manager, Lean Deployment Specialist, Business Excellence Leader, Senior Project Manager, and Industrial Performance Leader for Dacia, Honeywell, and Renault-Nissan.

- Responsible for the Alignment of the Honeywell Operating System at global level, Nicolae supported the global deployment of the Honeywell Production System “Order to Cash” across all Strategic Business Groups.

- Lead spin-off projects which transferred production facilities and distribution centers involving sites in UK, Germany, Italy, Romania and Czech Republic.

- Senior Quality Manager of Dacia Powertrain & Transmission Sites, leading a quality team of 260 members, awarded as best Power-Train site of Renault’s Powertrain Group for quality performance.

- At Renault-Nissan using Industry 4.0 methods he led Tiger Teams (Clubs Métier) for all Powertrain sites and involving departments of Energy Saving, Maintenance, Cutting Tools and Industrial Liquids

- Supported deployment of Build in Quality concept and approach, as “BiQ Subject Matter Expert”, across Transportation System Business Group in Honeywell, impacting reduction of non-added value and cost of poor quality.

- He led “Excellence Certifications” processes in USA, EMEA and APAC manufacturing and distribution site for over 40 locations, using as referential the Lean and 6 Sigma tools.

Edgar Cardenas

Vice-President Global Operations

Edgar has multicultural experience (Romania, Hungary, Japan, Russia, Mexico, Colombia, Spain, USA…) providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes in different industries including, Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, Aerospace, among others

- He has provided support to companies like Bosch, Inteva Products, Scandia, Hino Motors, Kimball, Zebra technologies, Takata, Continental, Dawn Foods, BOA RBT, Mars, Rubbermaid,, Emerson, Exide, Harsha Engineers, Steelcase.

- He has worked in several industries including, Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, Aerospace, among others

- Edgar is an advisor for several organizations at the leadership level, providing support in languages like English, Spanish and Romanian.

- Since 2014, Edgar has been developing coaches using the Toyota Kata approach, creating internal capability within the companies.

- He is an operational excellence speaker at the international level of Lean Conferences & Summits.

- He has developed and coached over 1000 managers & leaders in the Lean management philosophy.

- Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta, Georgia.

Data: 31 August – 2 Septembrie 2022

Cine ar trebui să participe?

Liderii care doresc să învețe cum să asigure calitatea îmbunătățindu-și produsele și cunoștințele despre procese prin intermediul acestui training de calitate.

Training de calitate – Obiective principale:

-

Definiți fundamentul unei culturi de zero defecte îmbunătățind cunoștințele despre produsul și procesele noastre.

-

Prezentați mecanisme și strategii pentru a înțelege mai bine toate elementele care fac parte dintr-un Sistem practic de calitate.

-

Examinați principalii factori pentru îmbunătățirea nivelurilor noastre de calitate prin participarea tuturor nivelurilor organizaționale.

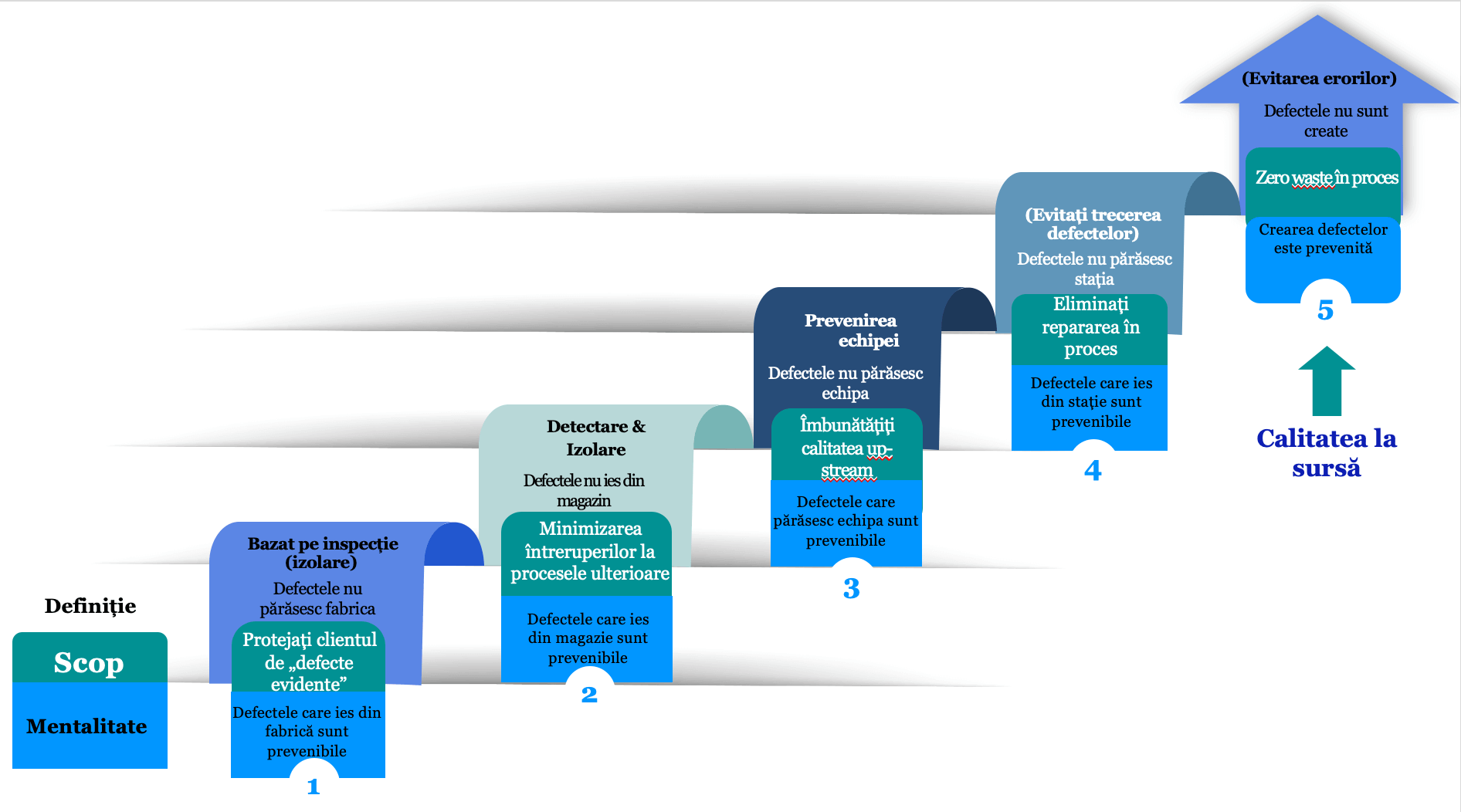

Conceptul Built-in Quality

Fabrica Gazdă: Inteva Products

Dedicată celor mai înalte standarde de calitate, Inteva îndeplinește toate cerințele și așteptările clienților. Compania este focusată pe angajamentul total oferit îmbunătățirii continue a produselor și a proceslor. Inteva are peste 15,000 de membrii de echipă în 18 țări. Inteva World Headquarters se află în Troy, Michigan.

Fabrica Inteva Products Salonta produce zăvoare, regulatoare de geamuri și cabluri mecanice pentru diverși producători auto de clasă mondială. Fabrica din Salonta a început implementarea Lean din 2016, atingând beneficii tangibile în performanță, dezvoltând echipele în rezolvarea oricărei probleme și învățare continuă.

Liniile noastre de produse includ Sisteme de Închidere, Sisteme Interioare, Motoare & Electronice și Sisteme de Acoperire, și avem mai mult de 90 de clienți, incluzând virtual toți fabricanții auto globali și regionali de top.

Built-in Quality își propune să lase doar produse bune pe tot parcursul procesului

Participanții se vor împărți în echipe pentru a desfășura activități în zona de proces și își vor prezenta observațiile

Învățare Practică

Învățați conceptele din exemple, exerciții de grup și experiența trainerilor

Discuții de Grup

Împărtășiți experiențe cu manageri din diferite industrii și medii

Exerciții în zona de producție

Trainingul este desfășurat în fabrică, cu activități directe în zona de proces

Niveluri Built-in Quality

Sold out!

Instructed by seasoned Lean Coaches

Andreea Selin

Quality & Continuous Improvement Director

Andreea has 9 years of implementing continuous improvement in diverse organizations. A proactive, committed and self-motivated change agent who facilitates the process of discovery to quickly make an impact on the way people think about work and continuous improvement.

After orchestrating lean transformations and improving organizational performance, eliminating wastes and creating flow, I can say that the most challenging, rewarding and enthusiastic experience is gaining people’s hearts and minds for continuous improvement

Andreea has worked for companies like Nokia, Protect & Gamble, Trelleborg and Celestica in roles like Engineering, Lean, Business unit manager and recently as Quality Director

Andreea has expertise in these fields: Change management, Value Stream Analysis, Problem Solving, Project management and Performance Coaching