Quick Response Quality Control (QRQC)

In-Field Training

„Calitatea nu este o chestiune de certificări sau instrumente, ci o chestiune de management”

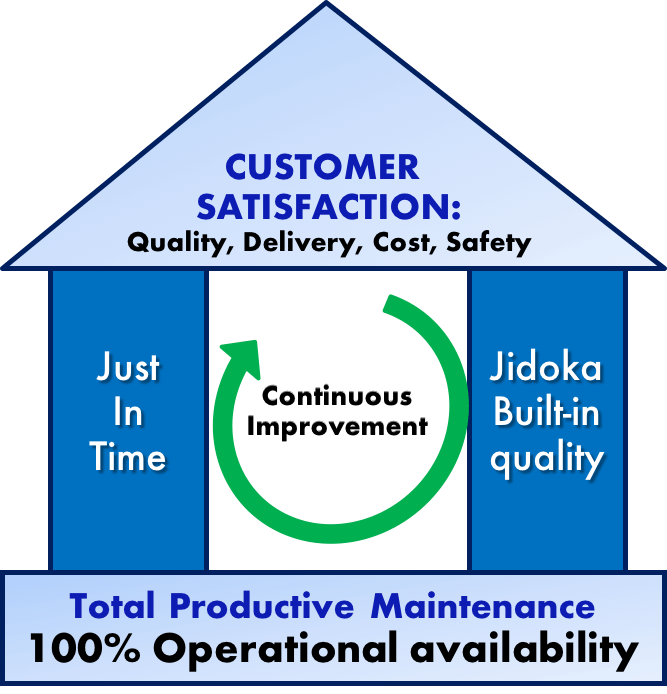

Cum se construiește un sistem Lean de calitate

O frustrare majoră pentru companiile este eșecul de a rezolva definitiv problemele recurente, chiar și atunci când implementează contramăsuri, problemele reapar.

Abilitatea de a rezolva aceste probleme necesită:

-

Abilități de analizat în zona de proces pentru a găsi cauza principală a problemei

-

Obțineți informații reale de la nivelul operatorilor pentru a rezolva rapid problemele.

-

Validați factorii care reproduc problema

-

Metode de verificare care ajută la menținerea oricărei contramăsuri

-

Elaborați opțiuni pentru prevenirea problemelor viitoare.

Quick Response Quality Control

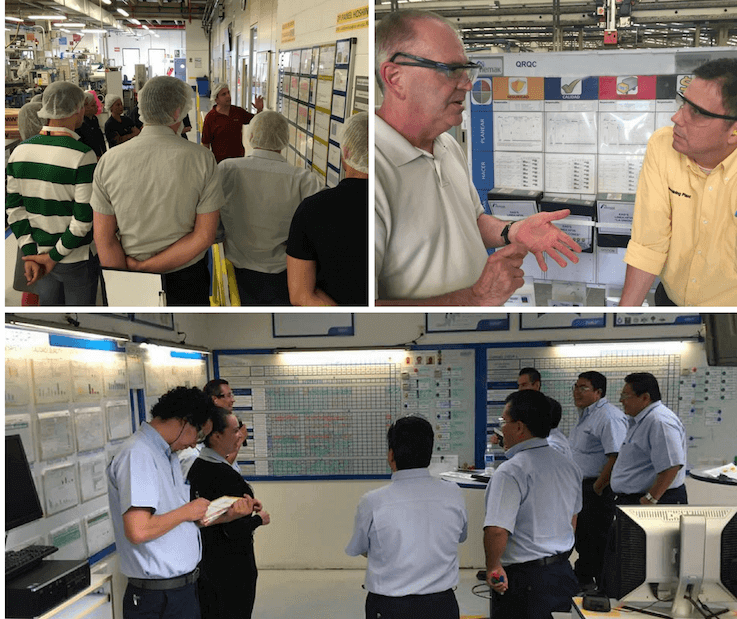

In-Field Training

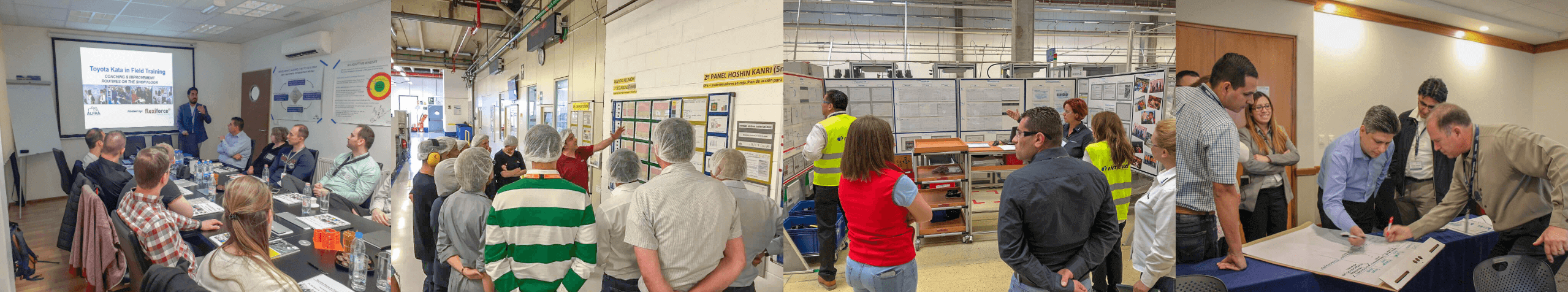

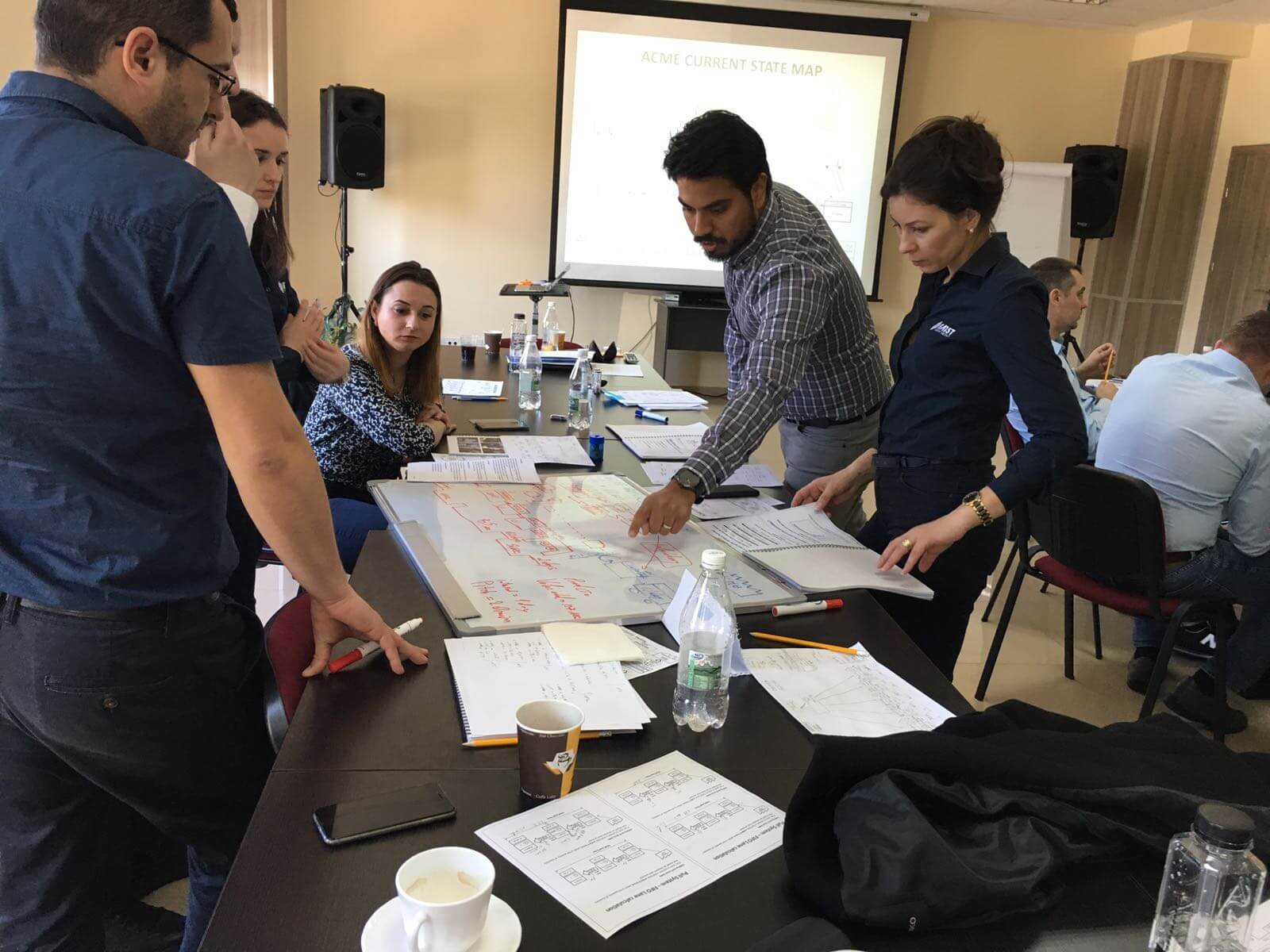

In-Field Training, practicăm conceptele în fabrica gazdă.

Observați QRQC în acțiune

Învățați și experimentați implementarea QRQC direct în zona de proces a fabricii gazdă.

Faceți echipă cu alți manageri

Împărtășiți experiențe și discutați cu colegii din diferite industrii

Exerciții în zona de producție

Exersăm conceptele direct la nivelul zonei de producție pe procese reale

In-Field Training, practicăm conceptele direct în zona de proces.

Aveți un sistem robust pentru a rezolva și preveni definitiv problemele?

Cum se construiește un sistem de calitate Lean

Durata training-ului: 3 zile

Cine ar trebui să participe? Manageri Generali, Manageri și Lideri din calitate, producție, inginerie și departamente lean

Beneficii principale ale QRQC:

- Rezolvați rapid și eficient problemele, preveniți apariția.

- Dezvoltați în echipa voastră o atitudine de management bazat pe realitate și Problem Solving

- Folosiți lecțiile învățate pentru proiecte viitoare pentru a îmbunătăți calitatea produselor și a proceselor.

Obiectivele Workshop-ului:

- Înțelegerea atitudinii San Gen Shugi

- Aplicarea practică a QRQC în zona de proces

- Aflarea sistemului de management necesar pentru o implementare cu succes

- Obținerea unei linii de ghidare pentru implementarea QRQC în propria companie

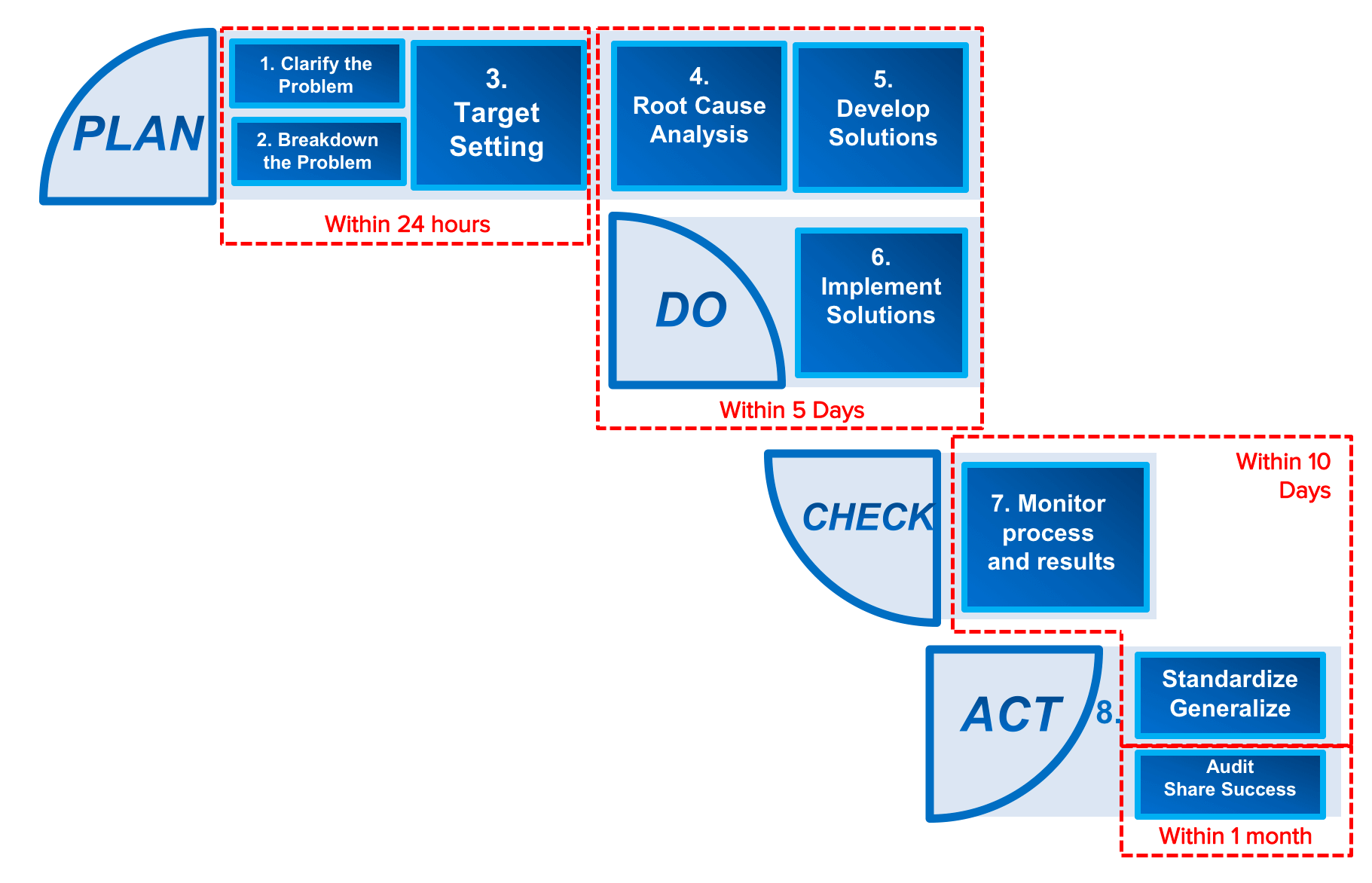

Ce este QRQC?

O abordare structurată pentru a răspunde rapid la problemele care apar intern sau la la clientul nostru, luând contramăsuri imediate și analizând pentru a dezvolta soluții care elimină reapariția problemei.

VREI SĂ MERGEȚI MAI DEPARTE? PUTEM RĂSPUNDE LA ORICE ÎNTREBARE

Customer complaint, 8D, QMS, Instruire, QRQC, Quick Response, Quality Control, Build in Quality, PDCA, Problem Solving, Automotive, Problem Solving, Build in Quality, Jidoka, 8D, PDCA, 5Why, Ishikawa, Trouble shooting, Built-in Quality, Quality Management, 5W2H, Customer Claims, 8 Disciplines, Quality Manager training, Quality Gates, Quick Response, Action plan, FMEA, Cause-Effect,