Quick Change Over (SMED)

Quick Change Over (SMED)

Online Training

Improving set up time in order to Increase flexibility.

Improving set up time in order to Increase flexibility.

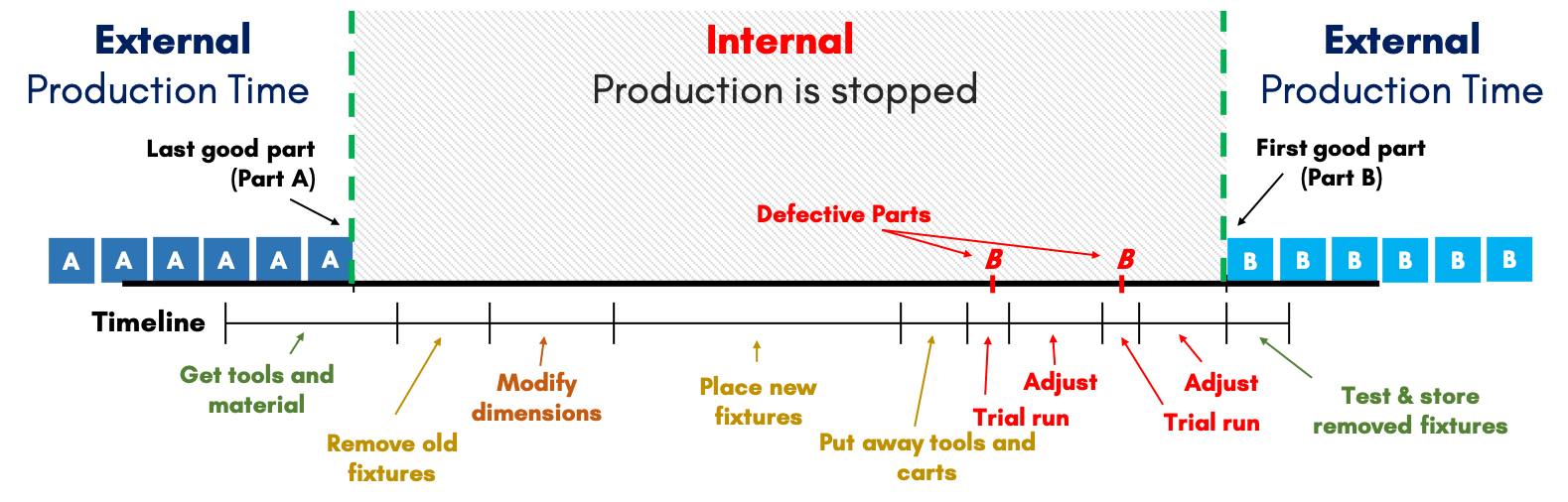

Changeover = Time to Change a from the Last Part of a Production Lot to the First Good Part of the next Production Lot.

Single Minute Exchange of Die (SMED) is a method developed by Shigeo Shingo and a cornerstone for Just in Time production, it originally looks to reduce the setup time in less than 10 minutes, today this approach is used to improve all kinds of setting activities.

Objective: understand the concept and practical implementation of SMED in order to set the foundations for Just in Time production and higher equipment availability.

Benefits of SMED:

Quick setups will enable you to:

-

Reduce the work in process and finish good inventory

-

Produce smaller batches of more varied products

-

Reduce your lead time to serve your customers faster

-

Instill the sense of urgency on your team.

Instructors

Edgar Cardenas

Lean Advisor & Coach – Europe Operations Director

Edgar has multicultural experience (Romania, Hungary, Japan, Russia, Mexico, Colombia, Spain, USA…) providing support to companies on their improvement journey based on developing teams to improve the quality of people & processes, in several industries including: Automotive, Electronics manufacturing, Food & Beverages, Plastics, Shared Service Centers, logistic services, among others.

- Edgar has led the ALFRA European operations since 2014, developing organizations in countries like Spain, Romania, Russia, or Hungary. He recently provides support to companies like Bosch, Hino Motors, Mercedes Benz, Kimball, Zebra technologies, Takata, Inteva Products, Dawn Foods, BOA, Mars, Rubbermaid, Faist Group, Emerson, Exide, Harsha Engineers, Steelcase.

- Edgar is an advisor for several organizations at the leadership level, providing support in languages like English, Spanish and Romanian.

- Since 2014, Edgar has been developing coaches using the Toyota Kata approach, creating internal capability

- He is an operational excellence speaker at international level Lean Conferences & Summits.

- He has developed and coached over 1000 managers & leaders in the Lean management philosophy.

- Certified as Lean Practitioner & Six Sigma´s Black Belt by the IIE, Atlanta , Georgia.

- Industrial Engineering & Management Bachelor Degree from Universidad Autonoma de Nuevo Leon.

- Edgar has received direct coaching and professional development from renowned leaders like:, Ritsuo Shingo (Former Toyota President ), PhD. Jeffrey Liker (The Toyota Way), Gary Convis (Former VP at Toyota N.A. )

Nicolae Gligor

Lean Management Senior Consultant

Nicolae has over 25 years of successful experience in different industries: Automotive, Chemicals, Automation & Electronics, Aerospace, leading the implementation of green field sites. Set the foundation for a Continuous Improvement culture and led Problem Solving projects of complex business issues across multiple sites in Europe, North America, Australia and Asia.

- He had roles such as Senior Quality Manager, Global Quality Improvement Manager, Lean Deployment Specialist, Business Excellence Leader and Industrial Performance Leader for Dacia, Honeywell and Renault-Nissan.

- Responsible for the Alignment of the Honeywell Operating System at global level, Nicolae supported the global deployment of the Honeywell Production System “Order to Cash” across all Strategic Business Groups.

- Lead spin-off projects which transferred production facilities and distribution centers involving sites in UK, Germany, Italy, Romania and Czech Republic.

- Former Senior Quality Manager of Dacia Power rain & Transmission Sites, leading a quality team of 260 members, awarded as best Power-Train site of Renault’s Mecanique Group for quality performance.

- At Renault-Nissan he led Tiger Teams in site departments of Energy Saving, Maintenance, Cutting Tools and Industrial Liquids by using Digital tools and Industry 4.0 approaches.

- Supported deployment of Build in Quality concept and approach, as Subject Matter Expert, across Transportation System Business Group impacting reduction of cycle time, non-added value and cost of poor quality.

- Certified as Six Sigma Black Belt, Lean Expert, Train the trainer, VDA and IATF

- He led “Excellence Certifications” processes in USA, EMEA and APAC manufacturing and distribution site for over 30 locations.

- MBA Professional Certificate in Management & MSc degree in Automotive Engineering – University of Pitesti, Romania

Date: 6-8 July

Location: Online Live via Zoom

Who should participate?:

Leaders and managers that are interested in learning a structured way of addressing problems and developing teams capable to properly identify, analyse, solve and prevent issues.

Why participate?:

- Learn how to make it easier and streamline any process to reduce idle time.

- The 4 steps method to analyze and improve the Change over the process

SMED Process

-

1) Document & classify activities

Document a “Dry-Run” Setup, and separate Events into Internal Setup and External Setup

-

2) Transform internal into externals activities

Convert any internal setup events to external setup events using focused, engineered methods.

-

3) Streamline internal events

Standardize activities to simplify, reduce, and Eliminate tasks.

-

4) Eliminating Adjustments and Trial Runs

Turn intuition and guessing into data and settings, 100% elimination of trial runs