Talent Development Programs

“We help you to untap your enterprise potential.”

Learn why our approach delivers results

On-site Trainings

Every company needs a specific approach depending on their actual situation, contact us so we can understand and guide you to establish the best training program.

Take advantage of performing a training focused on your operations and actual situation, with a tailored agenda specific for your team.

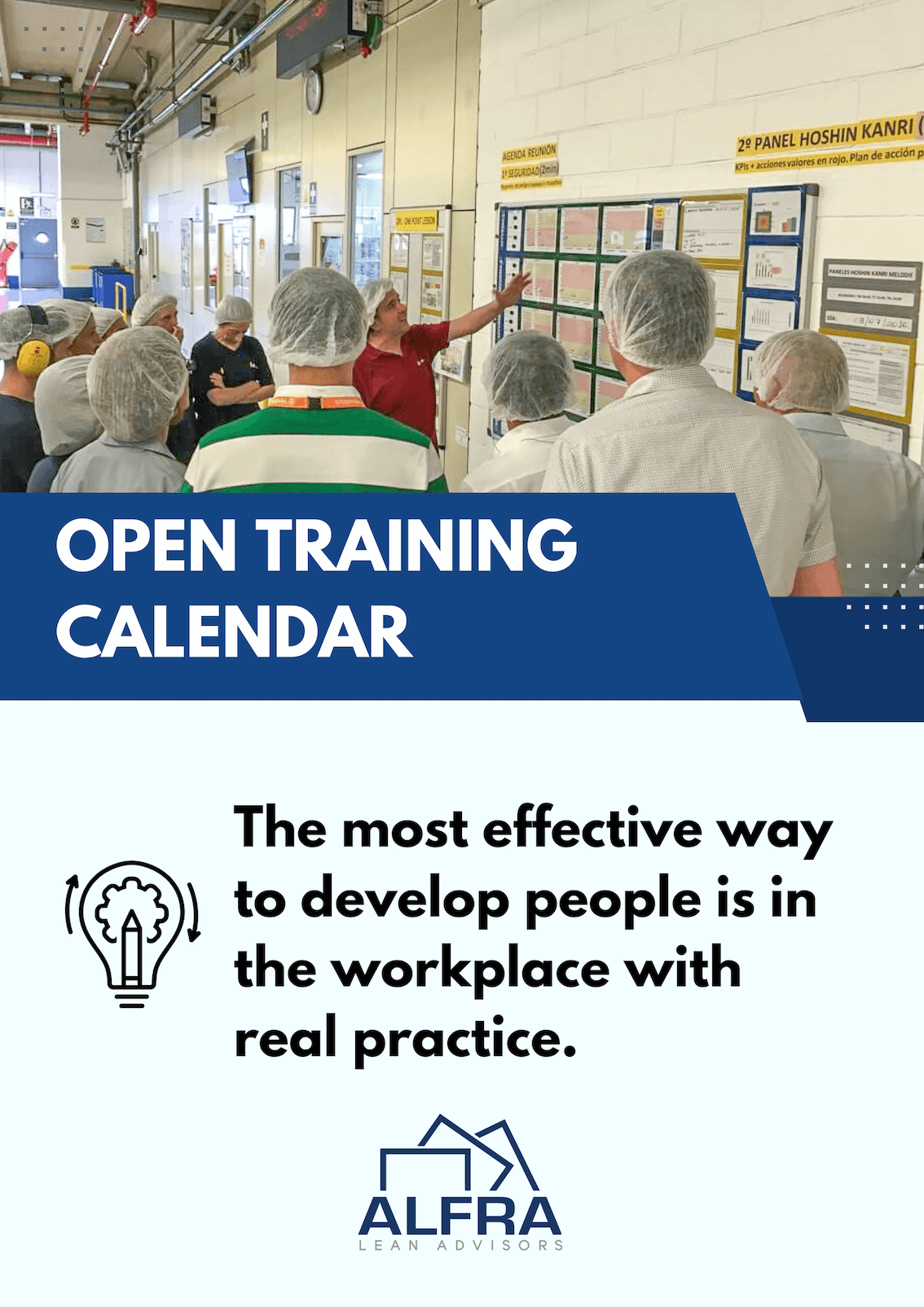

Open Trainings Calendar

We schedule trainings from our most required topics periodically, some of them are direct on the shop floor (Gemba), instructed by international and local experts.

Subscribe now to our Newsletter for the first notifications about the latest courses and activities.

Popular Trainings

Request a call with us to tailor a program for your team.

Participants’ feedback

- Lean Manufacturing

- 5S & Visual Management

- Standards Work

- Kanban System

- Lean Management for Business Processes

- Lean Management for Manufacturing

- 5S Training

- Lean Manufacturing Simulator

- Total Productive Maintenance

- Build in Quality

- Just in Time

- Value Stream Mapping & Design

- Lean for High Volume Low Mix (Make to Order) Production

- Cardboard Engineering

- Lean Supply Chain

- Lean Warehouse & Logistics

- Production Planning and Control

- Industrial Engineering

- Quick Changeover (SMED)

- Yamazumi Training

- Lean Strategy Deployment

- Making Materials Flow

- FMEA Training

- Shop floor Management (Superior performance teams & supervisors)

- Management by Value Streams

- Sustainable Team Building

- Human Resource Development

- Gemba Practice

- Train the Trainer

- Building and Sustaining Operational Workforce

- Emotional Intelligence

- Lean Expert Program

- Job Safety and Ergonomics Analysis

- Assertiveness Training

- Conflict Management

- Time Management